Monitoring equipment cleaning management device

A technology for managing devices and monitoring equipment, applied in combination devices, cleaning methods and utensils, cleaning methods using tools, etc., can solve the problems of blurred pictures, cameras will not be cleaned, and camera cleaning methods are inconvenient, and achieve high transparency. The effect of light, reducing the frequency of cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The following is further described in detail through specific implementation methods:

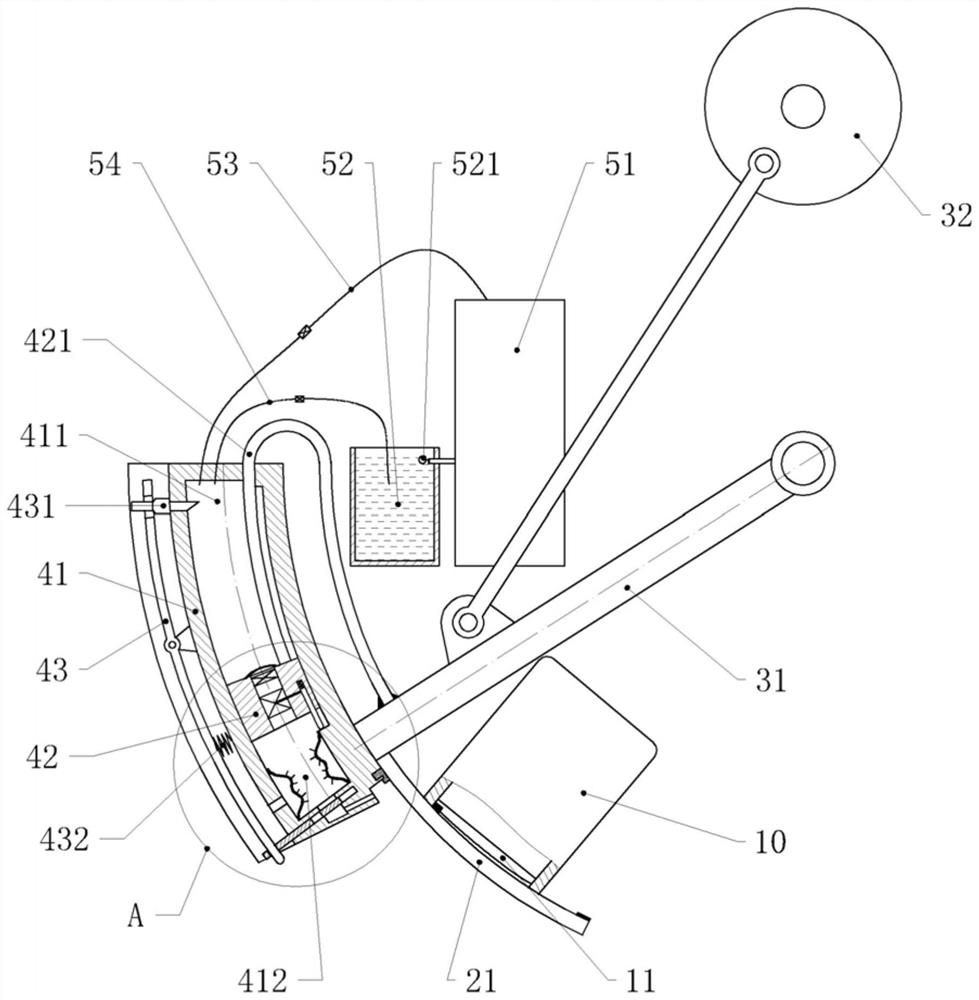

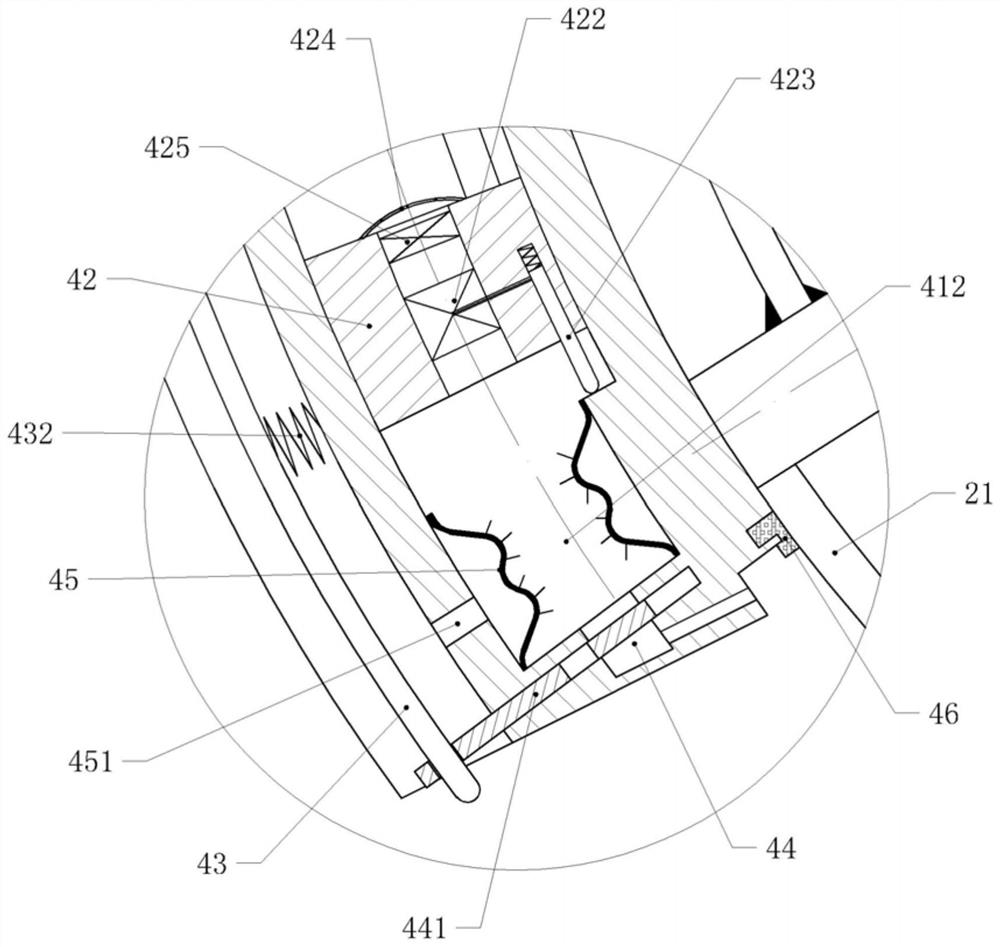

[0025] The reference signs in the drawings of the description include: camera 10, lens 11, cover 21, rocker 31, crank 32, cylinder 41, upper cavity 411, lower cavity 412, piston 42, U-shaped rod 421, exhaust valve 422, control pressure rod 423, net cover 424, exhaust one-way valve 425, control lever 43, wedge 431, compression spring 432, intake valve 44, valve core 441, elastic layer 45, through hole 451, dust strip 46 , main water tank 51, auxiliary water tank 52, float switch 521, second pipeline 53, first pipeline 54.

[0026] The embodiment is basically as attached figure 1, figure 2 Shown:

[0027] The monitoring equipment cleaning management device comprises a mounting frame, a camera 10 fixed on the mounting frame, and a cleaning management system arranged on the mounting frame. The cleaning management system includes an infrared sensor facing the same direction as the ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com