Honeycomb core glass fiber reinforced plastic floating disc for oil storage tank

A technology of honeycomb core and glass fiber reinforced plastic, which is used in containers, packaging, transportation and packaging, etc., can solve the problems of unsuitability of aluminum alloys

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

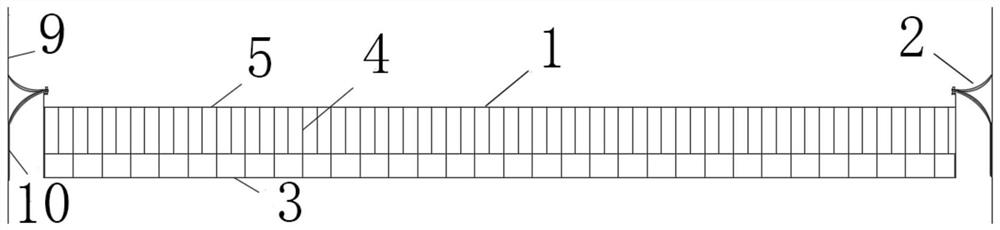

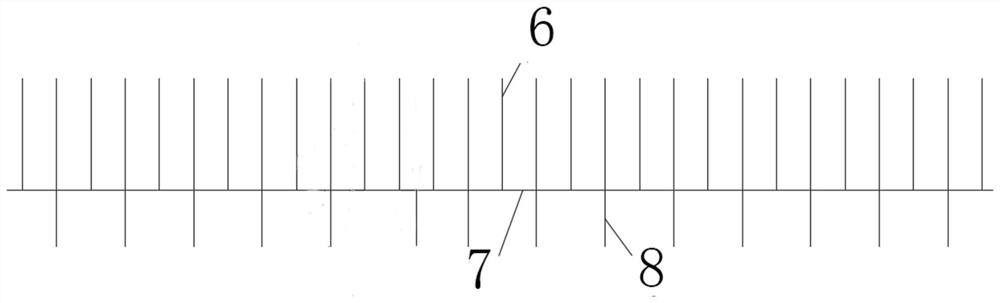

[0018] A honeycomb core FRP floating plate for oil storage tanks according to the present invention will be further described in detail below with reference to the accompanying drawings.

[0019] combined with Figure 1-2 , a honeycomb core FRP floating plate for oil storage tanks, comprising a floating plate body 1 and a sealing mechanism 2 cooperating with the floating plate body 1;

[0020] Described floating disc body 1 comprises floating disc lower bottom plate 3, the honeycomb core that is arranged on the upper side of floating disc lower floor bottom plate 3, the floating disc upper floor cover plate 5 that is arranged on the honeycomb core; Composed of core 6, partition board 7 and lower honeycomb core 8;

[0021] The sealing mechanism 2 includes tongue-shaped sealing scrapers 9 arranged at both ends of the floating disc body 1 and a full compensation sealing system 10 matched with the tongue-shaped sealing scrapers 9 .

[0022] The lower bottom plate 3 of the floati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Side length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com