Longitudinal-radial coupled vibration double-roller ultrasonic rolling welding device

A welding device and coupling vibration technology, applied in the field of double-roller ultrasonic rolling welding device, can solve the problems of wrinkling and poor welding sealing performance of multi-layer non-woven products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The technical solution of the present invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings.

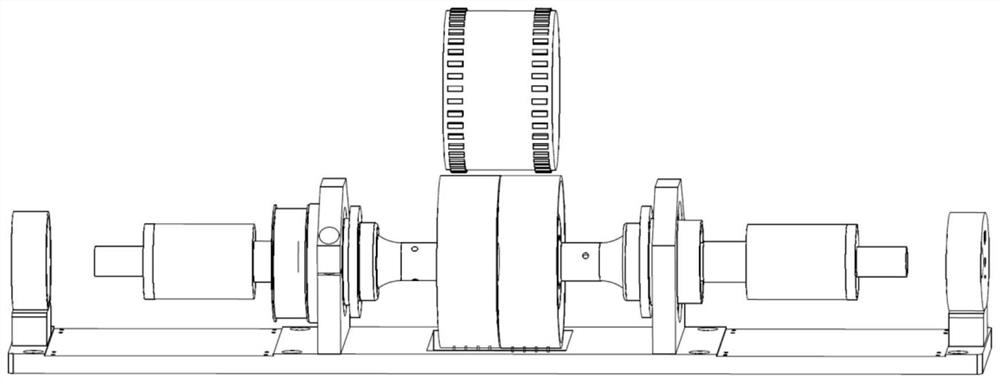

[0030] figure 2 The double-roller ultrasonic rolling welding device with longitudinal-diameter coupling vibration provided by the present invention includes an ultrasonic vibration part and a fixed clamping part; the ultrasonic vibration part includes a coaxially arranged double-roller roll welding tool head and an ultrasonic transducer.

[0031] The double-roller seam welding tool head is composed of two butt seam welding tool heads 12 . The seam welding tool head 12 includes an integrally processed end disc structure and an axial horn structure, and the overall cross-section is T-shaped; the radial resonance frequency of the end disc structure and the longitudinal resonance frequency of the axial horn structure The frequency is consistent during the coupled vibration process of rolling welding. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com