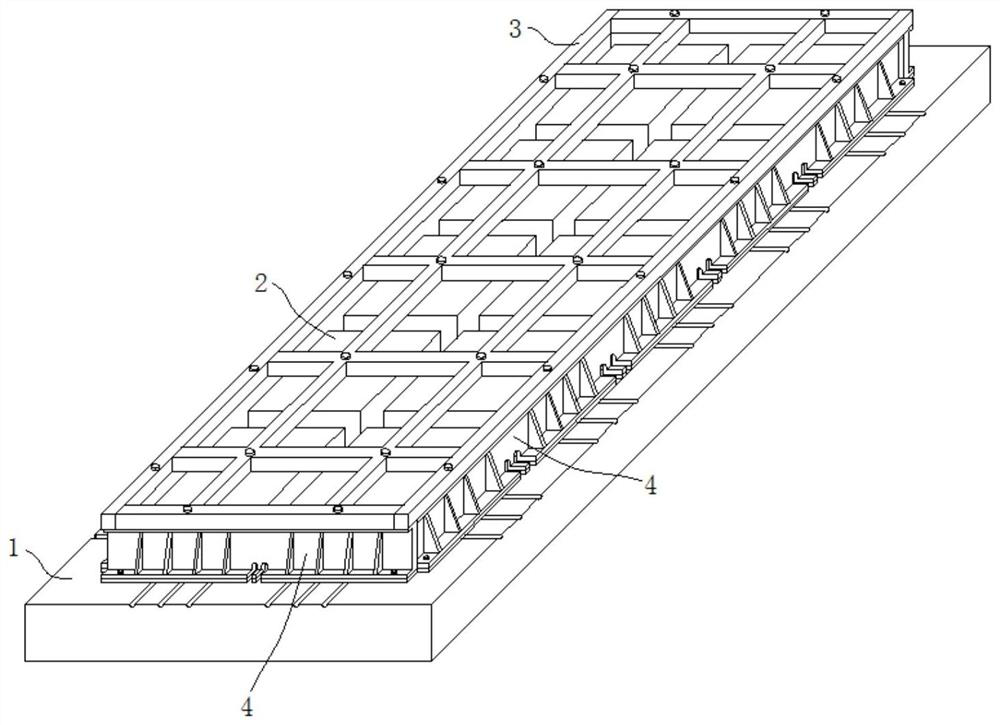

Forming die of cross beam prefabricated part and mounting and using method thereof

A prefabricated component and criss-cross technology, applied in mold fixtures, manufacturing tools, ceramic molding machines, etc., can solve problems such as difficult one-time molding and pouring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

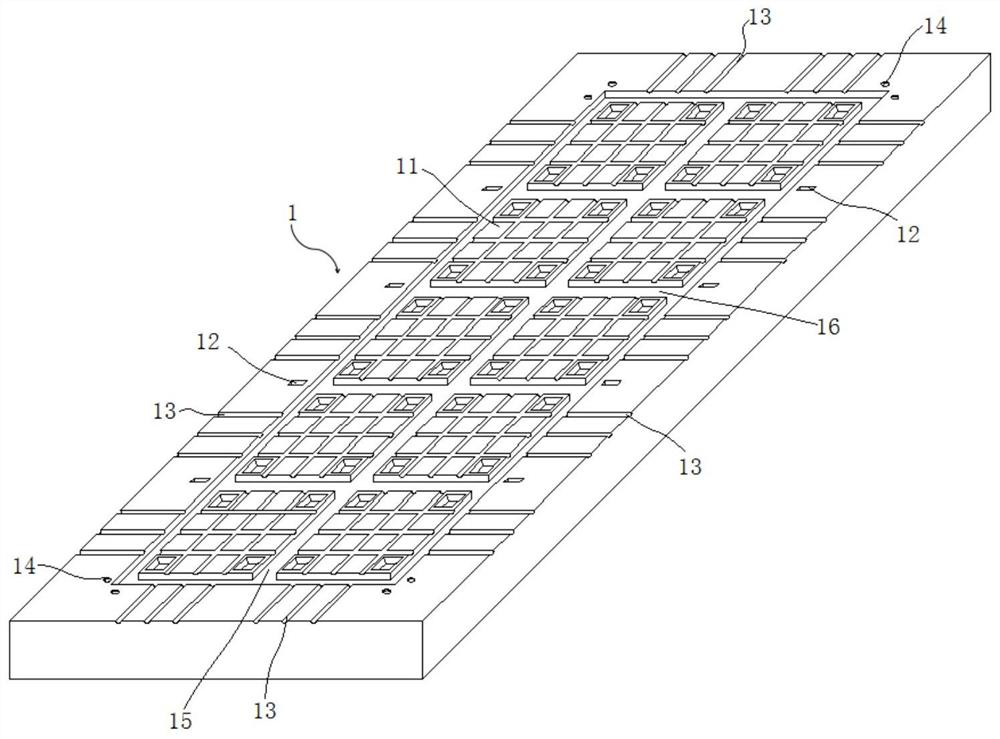

[0050] Such as Figure 8 As shown, the product cross beam prefabricated component 5 formed by one-time pouring using the molding die of a cross beam prefabricated component of this embodiment has a rectangular box structure, and the cross beam prefabricated component 5 includes surrounding side ribs 52, The outer surface of the rib 52 in the side area is provided with rib grooves 53 sunken inwards, and the ribs 52 in the side area form a cavity, and a plurality of rib beams 56 are evenly spaced along the length and width directions respectively, and the rib beams 56 connect the cross The internal cavity of the cross-beam prefabricated member 5 is divided into multiple rows and columns of grids, and the bottom of the grids is provided with a horizontal steel mesh 51, which is composed of a plurality of grid steel bars 55 vertically and horizontally intersecting, and the ribs The inner bottom of the beam 56 is also provided with matching rib beam reinforcement bars 54 , wherein ...

Embodiment 2

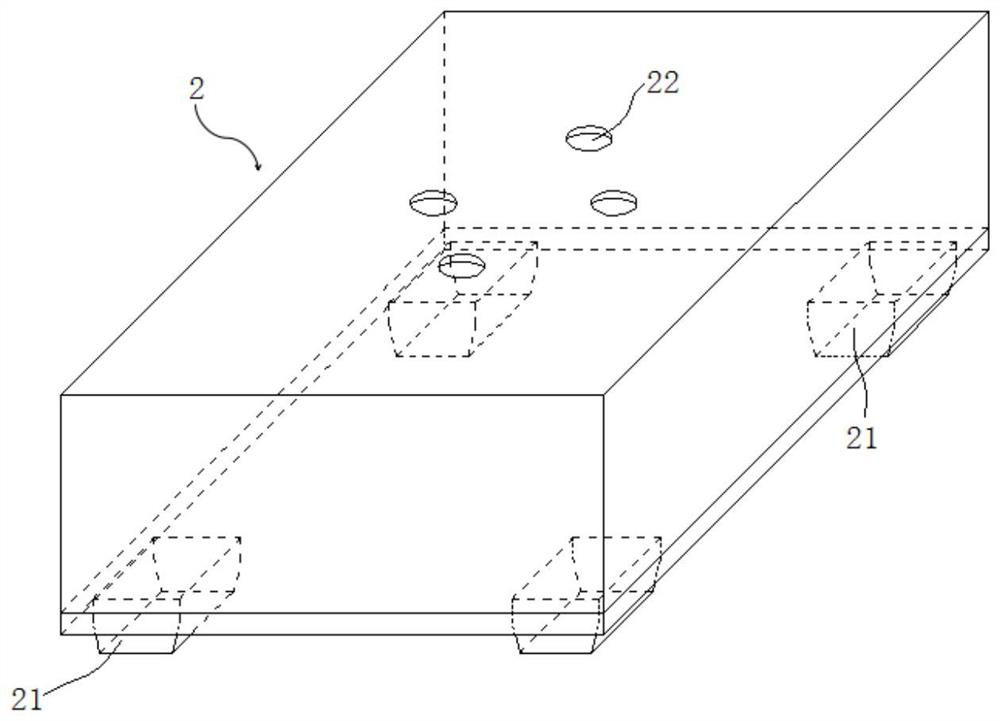

[0067] The molding die of a kind of cross beam prefabricated member of the present embodiment, basic structure is identical with embodiment 1, further, as Figure 4 As shown, the inner mold 2 in this embodiment is a thin-walled box, and the material is a steel plate or a hard plastic plate with a thickness of 3 mm to 5 mm. A reinforcing plate is provided inside the box to ensure that there is no obvious deformation when the concrete is vibrated. The lower part of the bottom plate of the inner mold 2 is provided with a layer of flexible cushion, and the thickness of the flexible cushion is 10mm-20mm. Specifically, the thickness of the flexible cushion layer in this embodiment is 10 mm. After the inner mold 2 is in place, it is pressed on the horizontal reinforcement mesh in block 11, and the flexible cushion layer contacts with the vertically and horizontally intersecting reinforcement on the horizontal reinforcement mesh and wraps the reinforcement extending out of block 11, w...

Embodiment 3

[0070] The forming die of a kind of cross beam prefabricated member of the present embodiment, basic structure is the same as embodiment 1, further, in the present embodiment, the side mold 4 is set up at the position of rib beam reinforcing bar 54 to pass through for reinforcing bar vertically. The rib beam reinforcement avoidance groove 45 in the length or width direction of the formwork, the rib beam reinforcement avoidance groove 45 penetrates the lower flange plate 43 downwards, the groove top of the beam reinforcement avoidance groove 45 is a semicircular arc structure, and the semicircular arc structure The depth is not less than 1 / 2 of the diameter of the rib beam steel bar 54, nor greater than the diameter of the rib beam steel bar 54, so the scope of adaptation is wider. In this embodiment, the bottom of the lower flange plate 43 of the side form 4 is laid with a layer of flexible cushion, which can effectively reduce the phenomenon of grout leakage when pouring concr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com