Auxiliary assembly tool for correcting perpendicularity and deflection of lower core of main body core

A technology for auxiliary assembly and main body, applied in the direction of tools, manufacturing tools, cores, etc., can solve the problems that assemblers need high ability and experience requirements, large errors, and high operation requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, but it should be understood that the protection scope of the present invention is not limited by the specific embodiments.

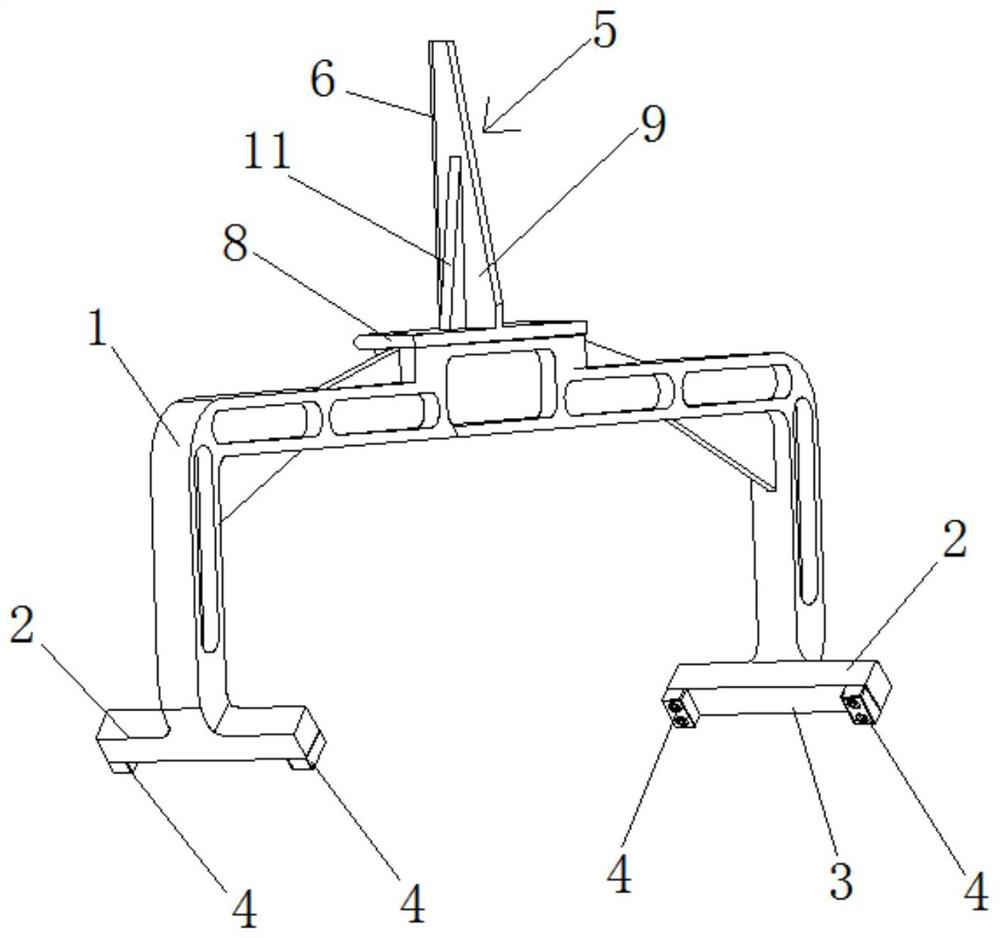

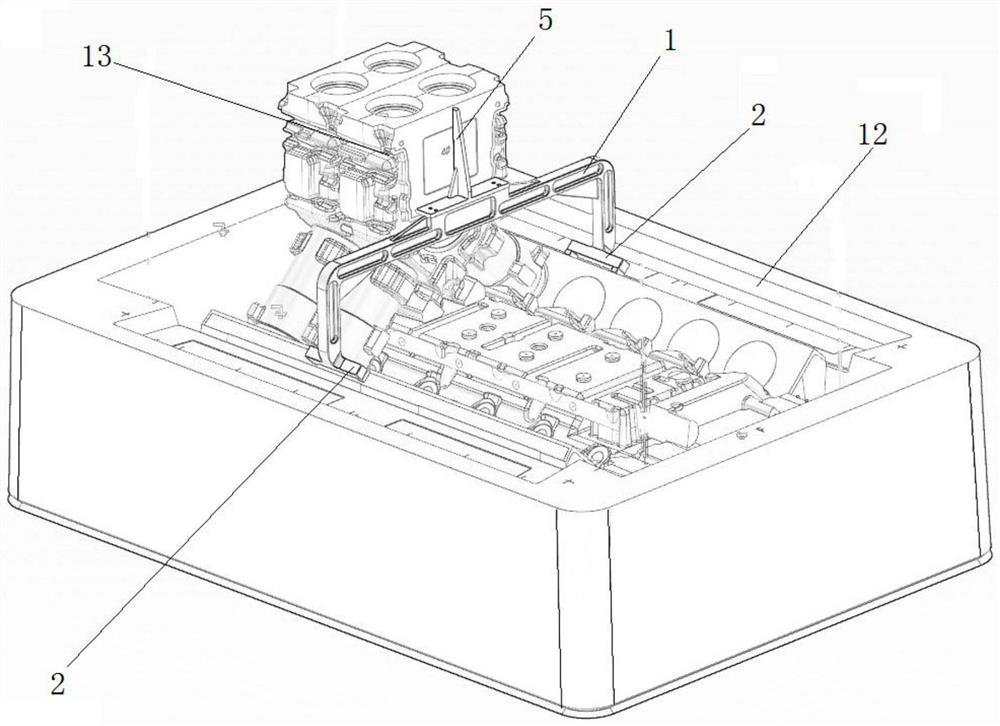

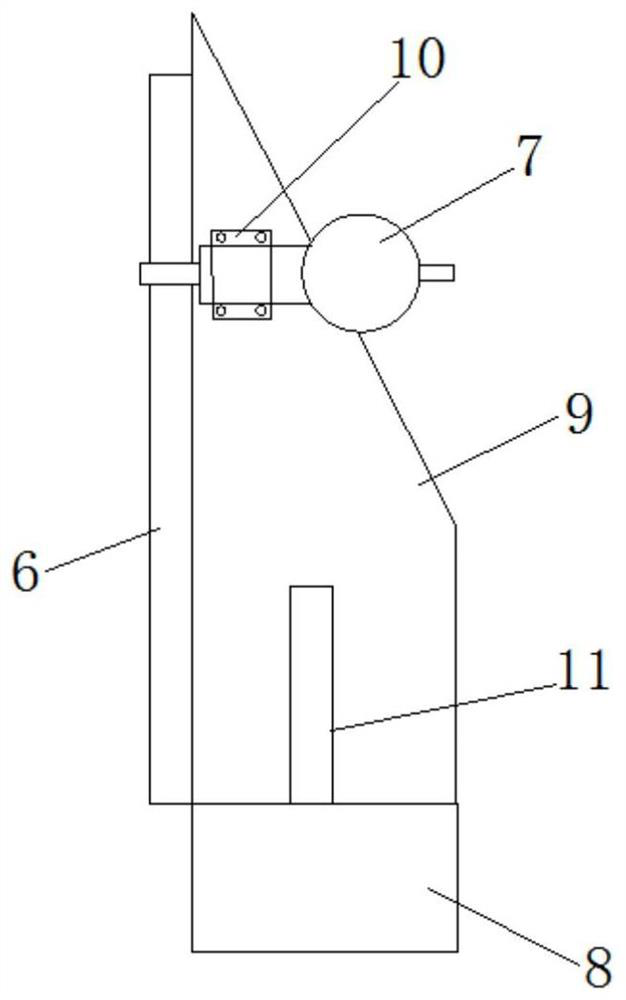

[0020] The specific embodiment of the present invention is like this: as Figure 1-3 As shown, an auxiliary assembly tool for correcting the verticality and deflection of the lower core of the main body includes a gantry 1, and two positioning slant seats 2 bent inwardly are arranged on both sides of the bottom of the gantry 1, and the positioning slant seats The inner side of 2 is provided with a positioning slope 3 inclined inwardly, and the two ends of the positioning slope 3 are provided with wear-resistant blocks 4, the top of the gantry 1 is provided with a detection needle 5, and one end of the detection needle 5 is provided with a detection end surface 6; In the auxiliary assembly tool used to correct the verti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com