Cutting and film pasting integrated cutting machine for grafting

A technology of cutting machine and cutting mechanism, which is applied in the direction of grafting, cutting tools, cutting equipment, etc., and can solve the problems of water entering the grafting incision, low efficiency, unstable and flat grafted branches, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

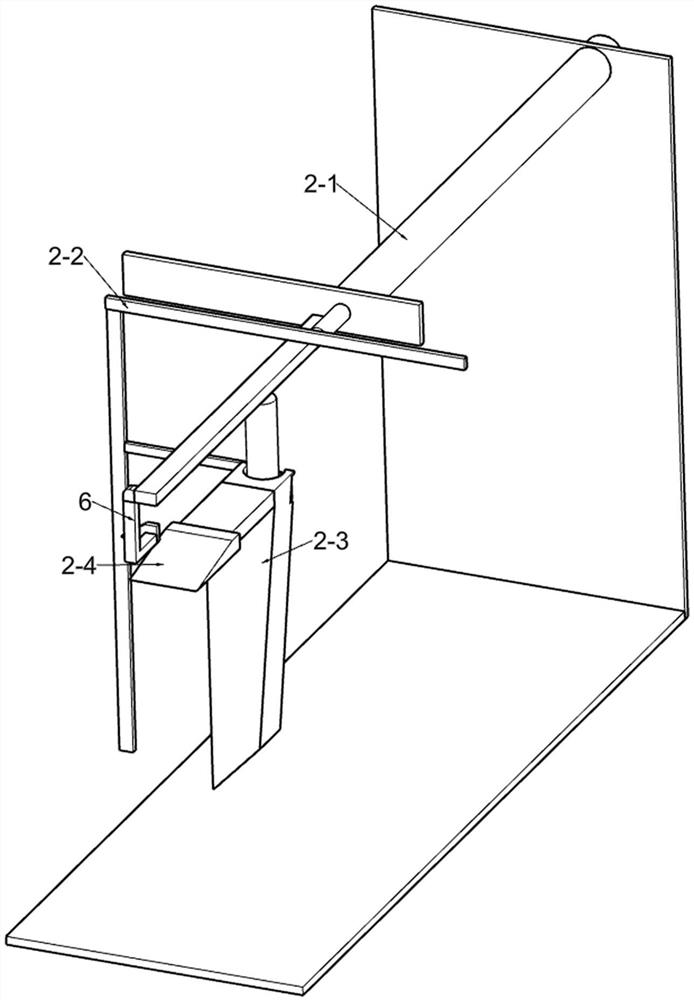

[0030] A cutting machine that integrates cutting and pasting films for grafting, such as Figure 1-2 As shown, it includes a portable frame 1, a cutting mechanism 2, a film sticking mechanism 3 and a clamping mechanism 4. One side of the portable frame 1 is provided with a cutting mechanism 2, and the cutting mechanism 2 is used to cut off and split the redundant part of the grafted rootstock. Stock, one side of cutting mechanism 2 is provided with film-sticking mechanism 3, and film-sticking mechanism 3 is used to carry out rotation film sticking to the branch of rootstock and scion, and one side of film-sticking mechanism 3 is provided with clamping mechanism 4, and clamping mechanism 4 can rootstock Clamping is carried out so that the follow-up of the branches of its rootstock and scion carries out tight film.

Embodiment 2

[0032] On the basis of Example 1, such as Figure 1-11 As shown, the cutting mechanism 2 includes an electric push rod 2-1, a first connecting bar 2-2, a vertical cutter 2-3 and a horizontal cutter 2-4, and the portable frame 1 is fixedly connected with an electric push rod 2-2. 1. One end of the telescopic rod of the electric push rod 2-1 is fixedly connected with the first connecting bar 2-2, and one end of the first connecting bar 2-2 is welded with a vertical cutter 2-3, and the vertical cutter 2-3 one side of the vertical cutter 2-3 is welded with a horizontal cutter 2-4, and the horizontal cutter 2-4 is positioned above the vertical cutter 2-3, and the vertical cutter 2-3 will The rootstock is split to be used for scioning, and the horizontal cutting knife 2-4 is used for cutting off the redundant rootstock for grafting.

[0033] The film pasting mechanism 3 includes a second connecting bar 3-1, a first rack 3-2, a third connecting bar 3-3, a second rack 3-4, a first fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com