Automatic rotary cutting fitting grafting machine

A grafting machine and cutting technology, which is applied in the fields of horticulture and vegetable seedling raising machinery, can solve the problems of low efficiency, effort, and energy consumption, and achieve the effects of increasing grafting speed, reducing labor intensity, and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention includes a frame 1, a frame 2, a cylinder 3, a side push rod 4, a guide groove 5, a guide rod 6, a spring 7, a push block 8, a push rod 9, a carding plate 10, a driving rod 11, and a groove plate 12 , baffle 13, slide block 14, cylinder 15, cylinder 16, earwood clamping claw 17, blade 18, pole 19, knife rest 20, pressure plate 21, cylinder 22, driving rod 23, support rod 24, rootstock clamping Claw 25, stop block 26, cylinder 27, cylinder 28, cylinder 29, switch 30, clamping plate 31, spring 32, support 33, put seedling clamping claw 34, drop seedling plate 35, drop seedling hole 36, spring 37, support 38, screw 39, supporter 40.

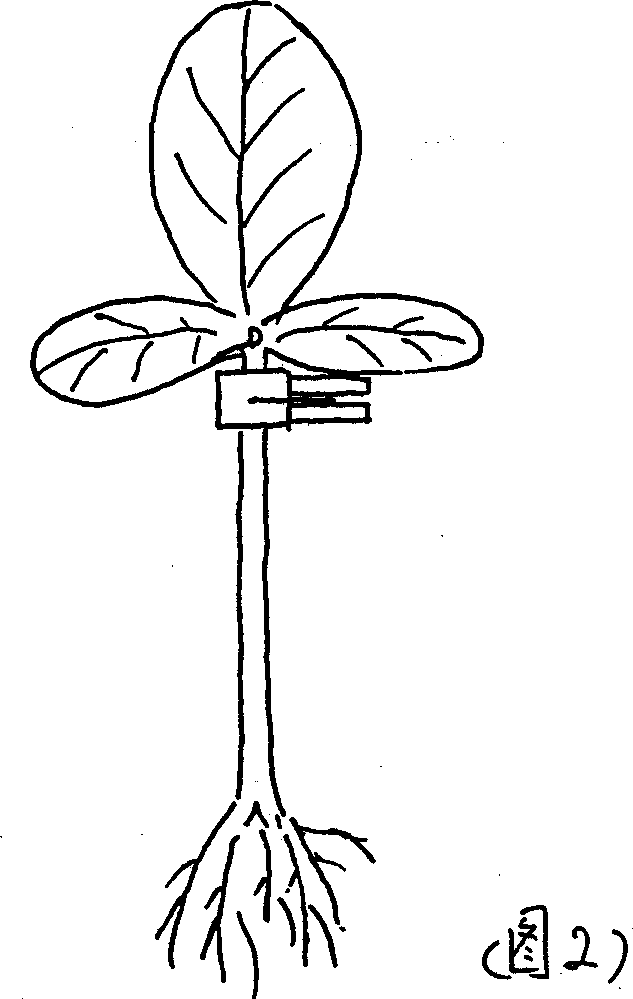

[0025] As shown in Figure 1 and Figure 2, the working process of rotary cutting and laminating grafting is: first cut an oblique incision along the end of the rootstock, cut off the cotyledon and the growth point of the rootstock; at the same time cut an oblique incision on the stem of the earwood. Finally, the cuts of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com