Fabric with open mesh structures and preparation method of fabric

A mesh structure and open technology, applied in knitting, warp knitting, textiles and papermaking, etc., can solve the problems of low production efficiency, single color of fabric surface, lack of three-dimensional effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

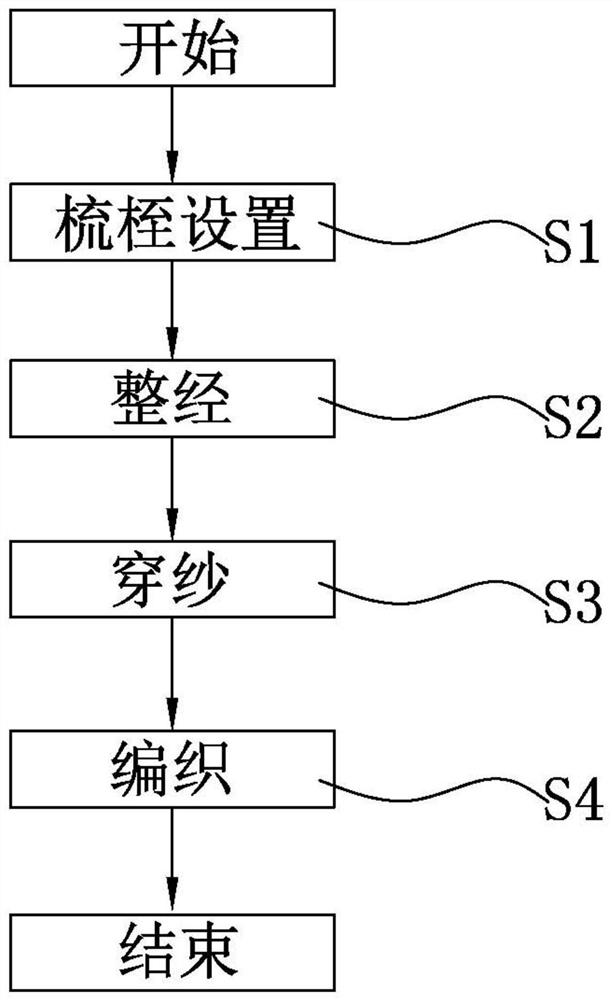

Method used

Image

Examples

Embodiment 1

[0047] refer to figure 1 , figure 2 , figure 1 It is the front view of the fabric with open mesh structure of the present invention; figure 2 It is a cross-sectional view of a fabric having an open mesh structure according to the present invention.

[0048] This embodiment provides a fabric with an open mesh structure, including a surface layer, a bottom layer, a connecting layer and a jacquard layer.

[0049] The surface layer includes a plurality of first yarns, a plurality of the first yarns are cross-woven to form the surface layer, and several mesh structures are formed on the surface layer, and each mesh structure includes a plurality of open meshes, A plurality of closed meshes, the shape of the open meshes is circle, ellipse, crescent or polygon.

[0050] Each of the mesh structures is arranged parallel to each other, and the length of each of the mesh structures is the same, and the length gradually changes or the length changes alternately.

[0051] Each of th...

Embodiment 2

[0069] refer to figure 1 , figure 2 , figure 1 It is the front view of the fabric with open mesh structure of the present invention; figure 2 It is a cross-sectional view of a fabric having an open mesh structure according to the present invention.

[0070] This embodiment provides a fabric with an open mesh structure, including a surface layer, a bottom layer, a connecting layer and a jacquard layer.

[0071] The surface layer includes a plurality of first yarns, a plurality of the first yarns are cross-woven to form the surface layer, and several mesh structures are formed on the surface layer, and each mesh structure includes a plurality of open meshes, A plurality of closed meshes, the shape of the open meshes is circle, ellipse, crescent or polygon.

[0072] Each of the mesh structures is arranged parallel to each other, and the length of each of the mesh structures is the same, and the length gradually changes or the length changes alternately.

[0073] Each of th...

Embodiment 3

[0091] refer to figure 1 , figure 2 , figure 1 It is the front view of the fabric with open mesh structure of the present invention; figure 2 It is a cross-sectional view of a fabric having an open mesh structure according to the present invention.

[0092] This embodiment provides a fabric with an open mesh structure, including a surface layer, a bottom layer, a connecting layer and a jacquard layer.

[0093] The surface layer includes a plurality of first yarns, a plurality of the first yarns are cross-woven to form the surface layer, and several mesh structures are formed on the surface layer, and each mesh structure includes a plurality of open meshes, A plurality of closed meshes, the shape of the open meshes is circle, ellipse, crescent or polygon.

[0094] Each of the mesh structures is arranged parallel to each other, and the length of each of the mesh structures is the same, and the length gradually changes or the length changes alternately.

[0095] Each of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com