Wastewater recovery treatment equipment

A technology for treatment equipment and waste water recovery, applied in filtration loops, filtration separation, separation methods, etc., can solve problems such as unsatisfactory treatment effect, defects in waste water treatment quality and efficiency, and lack of maintenance in structural design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

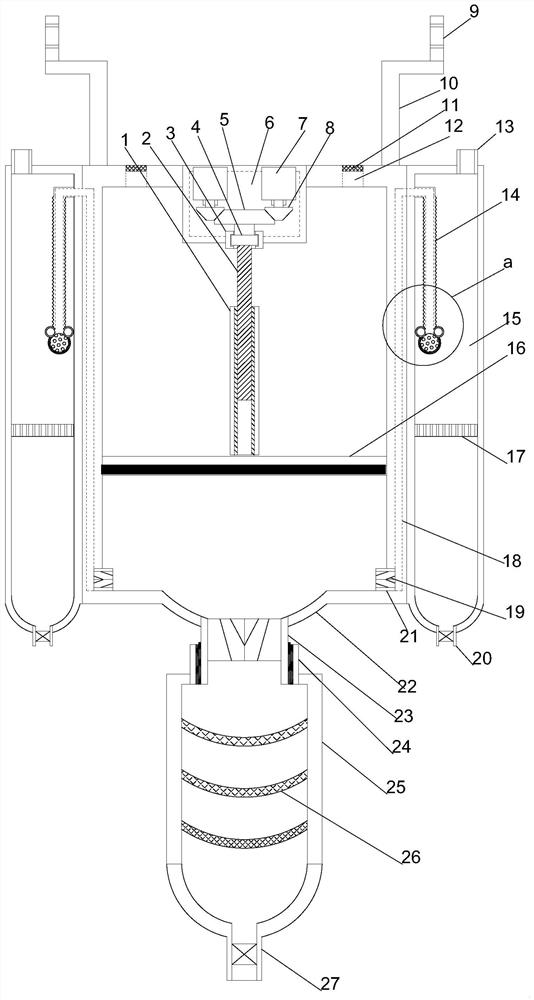

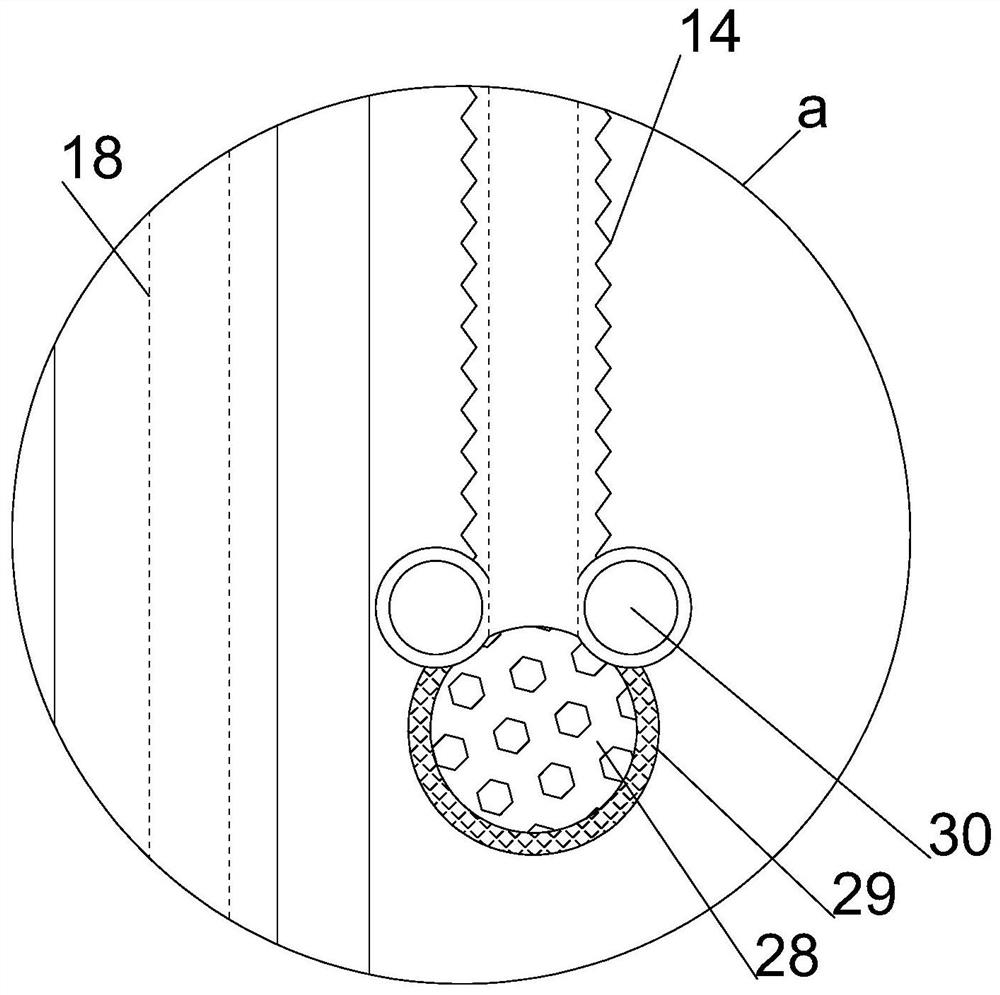

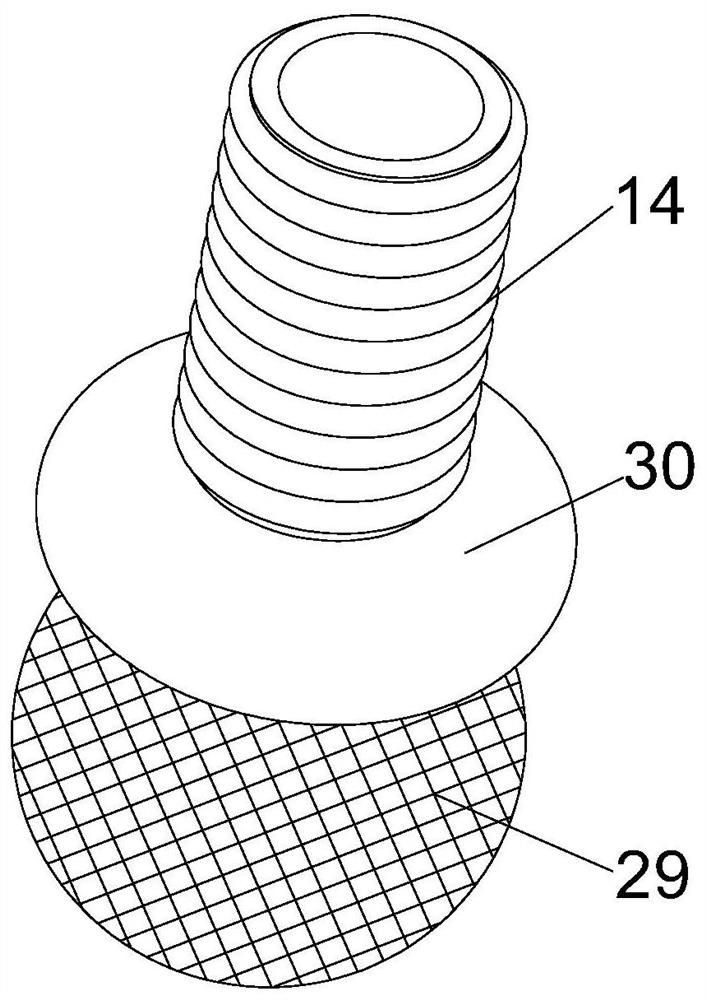

[0021] see Figure 1~3 , in an embodiment of the present invention, a waste water recovery and treatment equipment includes a vertically arranged support installation cylinder 22, and a plurality of support installation frames 10 are vertically arranged at an equal angle on the upper edge of the support installation cylinder 22, and the upper ends of the support installation frames 10 are arranged vertically. A fixed installation ring 9 is provided, and a transmission installation cylinder 6 is vertically arranged in the middle position of the upper end of the support installation cylinder 22. The upper end of the support installation cylinder 22 cooperates with the transmission installation cylinder 6 to vertically penetrate at an equal angle and is provided with a number of diversion holes 12. The upper ends of the holes 12 are provided with air intake filter screens 11, the inside of the support installation cylinder 22 is horizontally provided with a lifting piston 16, and ...

Embodiment 2

[0024] On the basis of Embodiment 1, after the wastewater has been purified for a period of time, the liquid in the liquid storage cylinder 15 is exported from the sewage pipe 20 through the control of the electromagnetic valve, and the sediment is also exported at the same time, then the electromagnetic valve is closed, and the above operations are repeated. In the purification operation, through the cooperation of the external thread installation cylinder 23 and the internal thread installation cylinder 24, the rapid replacement of the filter installation cylinder 25 is realized, the efficiency and quality of purification are significantly improved, and the maintainability is better.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com