Dynamic stress testing method for runner of water turbine

A test method and water turbine technology, applied in the direction of automobile tire testing, etc., can solve the problems of slow progress, affecting the reliability of test data, and limiting the measurement accuracy of the measurement system.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

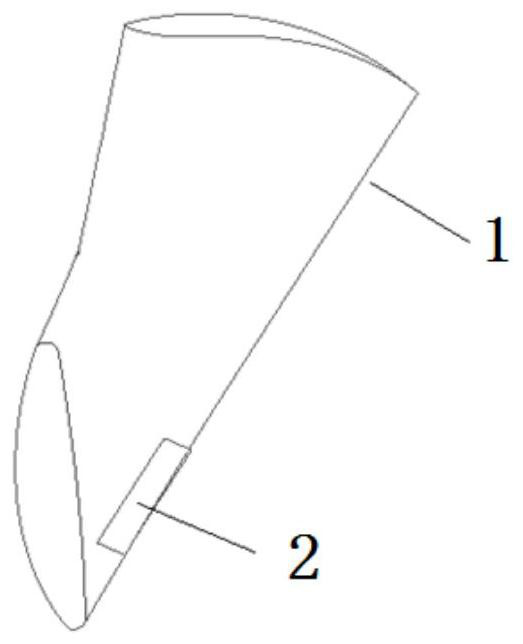

[0081] The static stress and dynamic stress of the runner blades are tested, and the dynamic stress data of the blades are collected under different start-up modes.

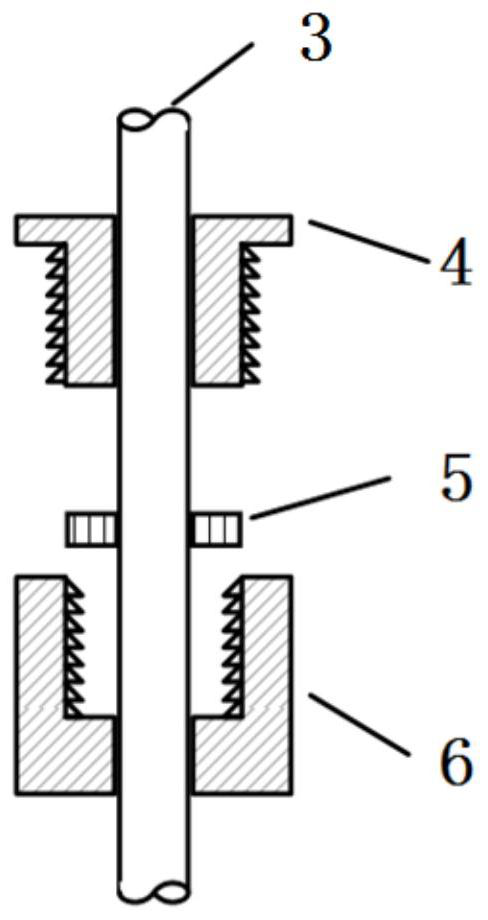

[0082] Goupitan Hydropower Station has the characteristics of high water head, large fluctuation of upstream and downstream water levels, frequent start-up and load adjustment, etc. Its water head ranges from 200m to 144m, and its rated water head is 175.5m. There are 5 installed machines in the underground plant, with a single unit capacity of 600MW, 16 runner blades, 7m runner inlet diameter, 125r / min rated speed, and clockwise when viewed from above. The air supply valve structure of the main shaft of the unit is an air buffer type air supply valve plus a porous floating ball valve seal. During the overhaul of No. 2 unit, install the strain gauges and debug the test equipment, and start the test after the overhaul is completed. The gross water head is about 167m during the test.

[0083] 1 Measuring point la...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap