Temperature control type hydraulic cooling system

A cooling system and temperature-controlled technology, which is applied in the field of hydraulic cooling systems, can solve the problems that the oil temperature cannot be adjusted in real time, the flow of oil in the circuit cannot be adjusted, and the temperature adjustment is not timely and accurate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

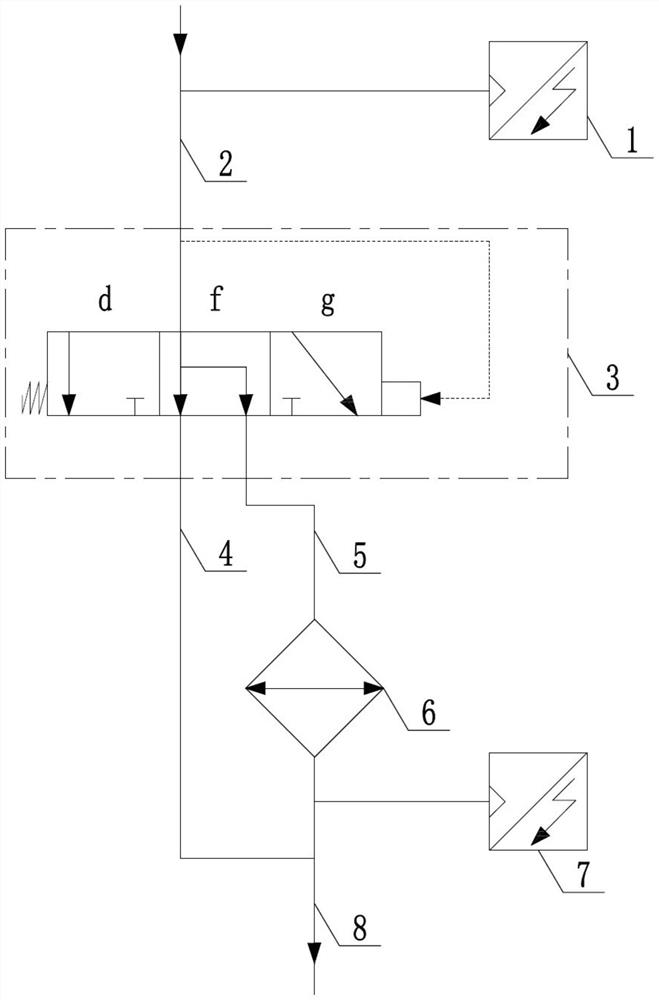

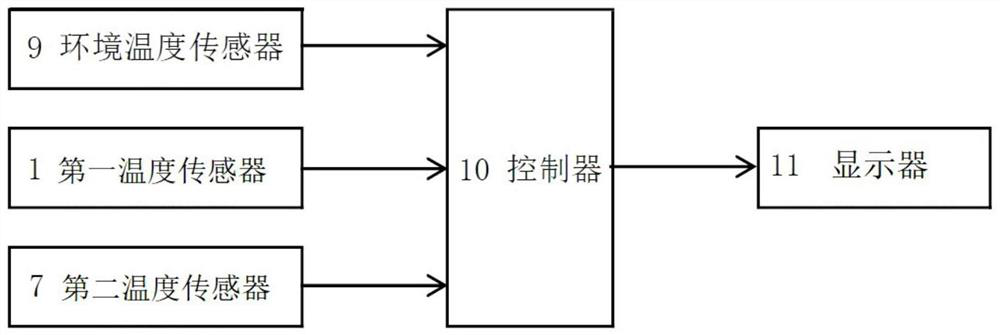

[0023] The invention discloses a temperature-controlled hydraulic cooling system, which is used to regulate the oil temperature of the hydraulic system, such as figure 1 , 2 As shown in . A branch oil passage 4 and a second branch oil passage 5 are connected to an oil return pipeline 8 . The radiator is arranged on the second branch oil circuit.

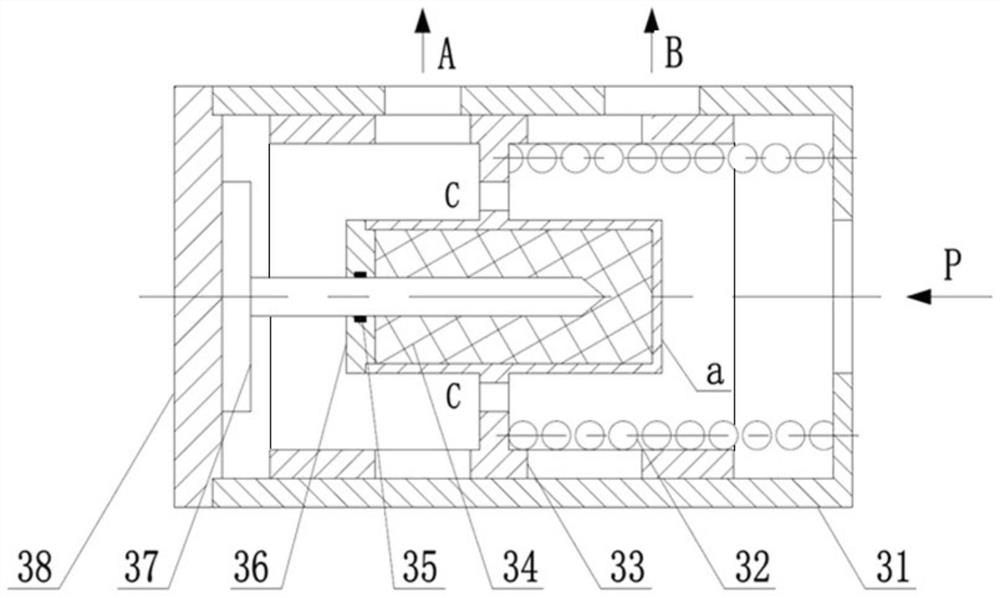

[0024] The temperature control valve includes a valve sleeve, a heat-sensitive material 34 located in the inner cavity of the valve sleeve, a spring 32 and a valve core 33 slidingly fitted with the valve sleeve. The two ends of the spring are respectively fixedly connected to the valve sleeve and the valve core, and the deformation direction of the spring is parallel to the sliding direction of the valve core. The heat-sensitive material is affected by the temperature change of the oil in the inner cavity of the valve sleeve to cause thermal expansion and contraction deformation. The heat-sensitive material and the spring work tog...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com