Antibacterial medical non-woven fabric and preparation process thereof

A preparation process and technology of non-woven fabrics, applied in non-woven fabrics, textiles and papermaking, needle punching machines, etc., can solve the problems of inability to meet non-woven fabric processing, relatively high degree of entanglement and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] This embodiment discloses a preparation process of antibacterial medical non-woven fabric, comprising the following steps:

[0032] Step S1, using a preparation system to prepare a non-woven fabric, and sequentially opening, carding, laying and spunlace the composite raw material fibers to obtain a non-woven fabric;

[0033] Step S2, drying the non-woven fabric prepared in step S1, controlling the drying temperature to 95-120°C, and after drying, the moisture content is 20-30%;

[0034] Step S3, washing the non-woven fabric prepared in step S2 three times with water, and neutralizing it with 3% acetic acid solution, so that the pH value of the non-woven fabric is 5.0-8.0;

[0035] Step S4, drying the non-woven fabric prepared in step S3, controlling the drying temperature to 95-120°C, and controlling the moisture content to 8-10%;

[0036] Step S5, cooling and rolling the nonwoven fabric obtained in S4.

[0037] In step S1, the composite raw fiber includes 40-50% by m...

Embodiment 2

[0041] This embodiment discloses another antibacterial medical non-woven fabric preparation process. On the basis of Example 1, a preparation system is used to prepare the non-woven fabric in step S1. Refer to figure 1 shown.

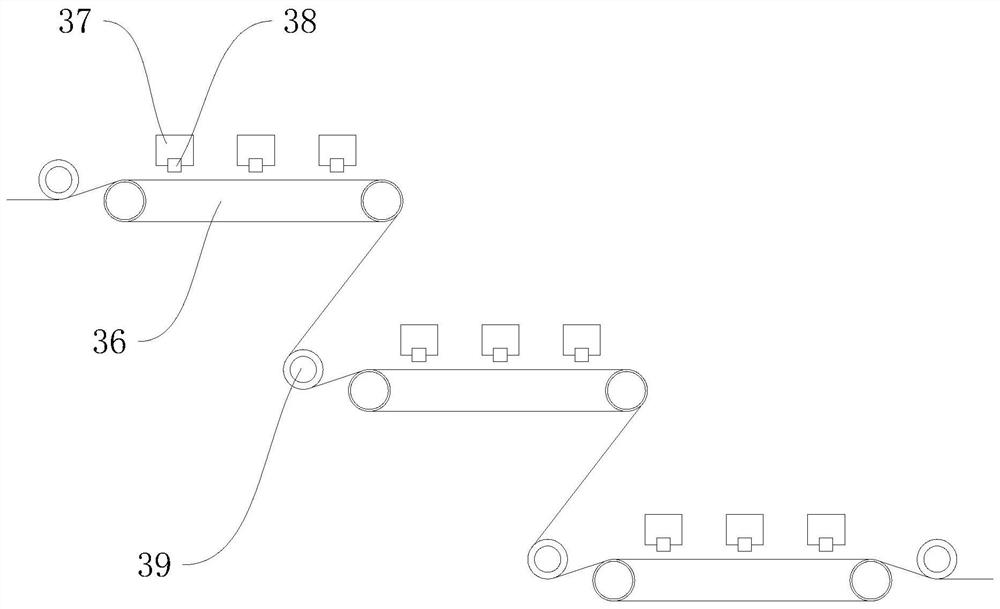

[0042] The preparation system includes three sets of spunlace devices, the spunlace devices include a conveying mesh belt 36 on which several spunlace components 37 are arranged, and several spunlace components 37 are evenly arranged along the conveying direction of the conveying mesh belt 36 , Adjacent spunlace devices are connected by guide rollers 39 to transport the non-woven fabric.

[0043] When the non-woven fabric passes through the position between the conveying mesh belt 36 and the spunlace head 38, the spunlace head 38 can spunlace the fibers in the non-woven fabric, so that the fibers are entangled and form a stable fabric structure; The spunlace strength in the three sets of spunlace devices decreases sequentially with the delivery sequenc...

Embodiment 3

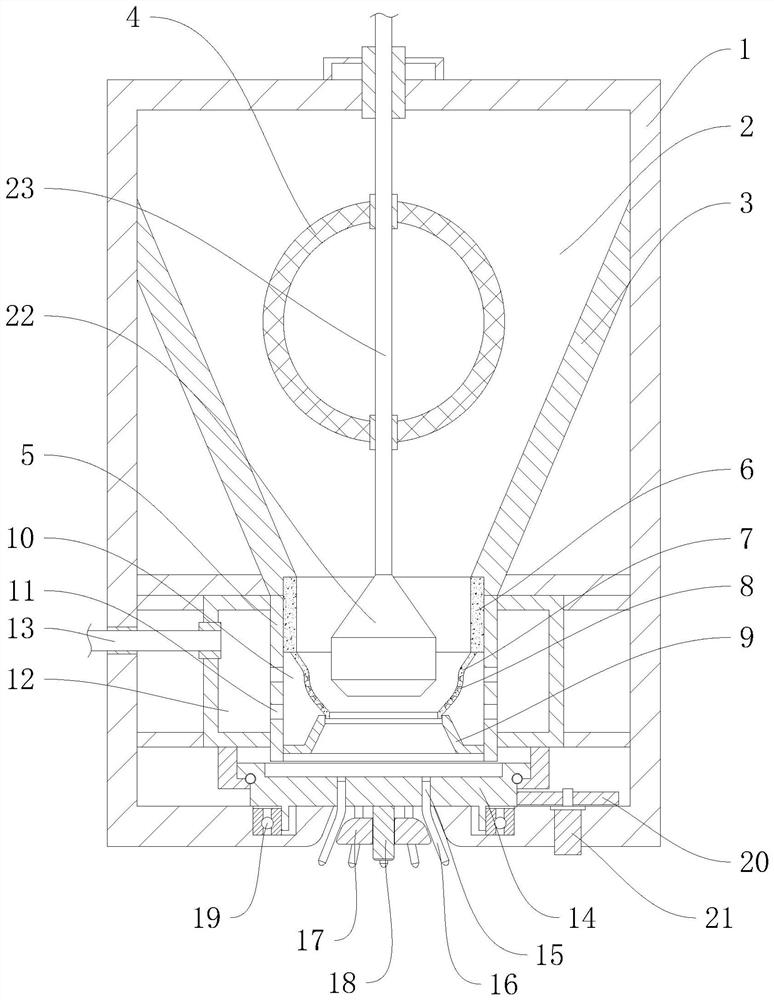

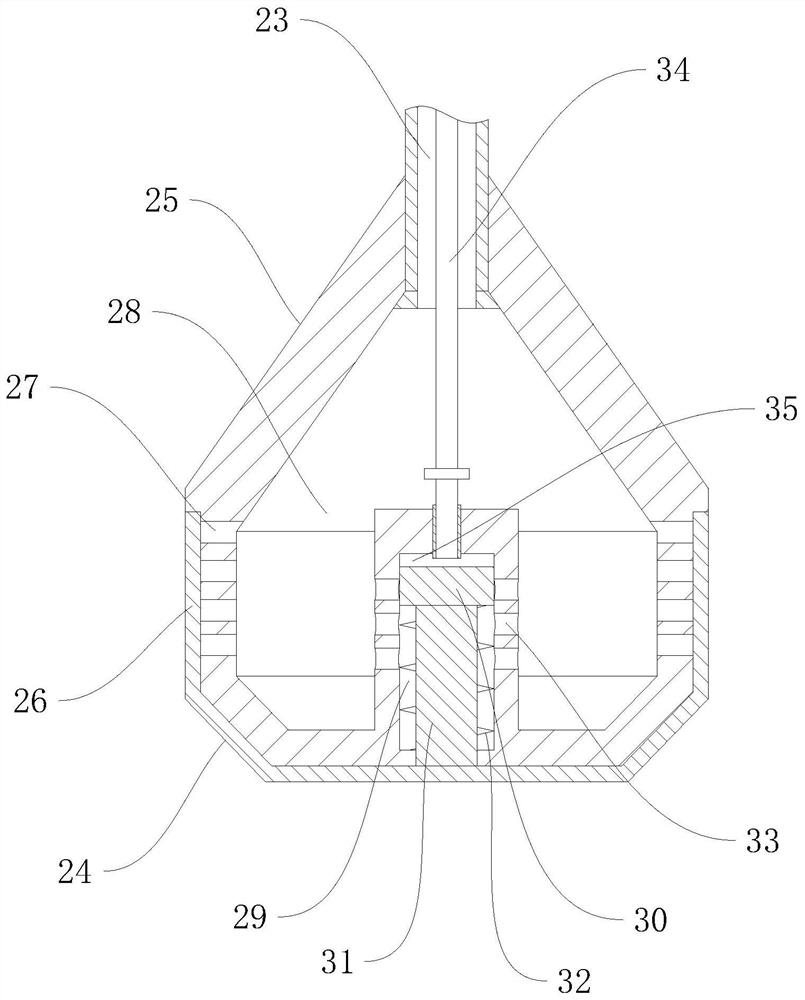

[0045] This embodiment discloses another antibacterial medical non-woven fabric preparation process, on the basis of embodiment two, refer to Figure 1-Figure 2 To illustrate, the hydroentanglement head 38 in the hydroentanglement device is further optimized to enhance the effect of hydroentanglement.

[0046] The spunlace device uses spunlace reagents to spunlace various fibers in the non-woven fabric, wherein the spunlace head 38 is provided with a high-pressure liquid chamber 2, which is set in the width direction of the non-woven fabric, and is placed in the high-pressure liquid A filter tube 4 is set in the cavity 2, and the water inlet position in the high-pressure liquid cavity 2 is located in the filter tube 4, so that the filter tube 4 can filter the impurities in the spunlace reagent and prevent the impurities in the spunlace reagent from clogging the spunlace head 38 .

[0047] Two inverted cone-shaped baffles 3 are installed at the lower part of the high-pressure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com