Carriage with inner container

A technology for carriages and linings, which is applied to vehicle components, superstructures and superstructures of trucks, etc., can solve the problems of increasing labor costs and time costs, lengthening freight time, reducing economic benefits, etc., and achieves easy promotion, The effect of reducing transportation costs and fuel consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

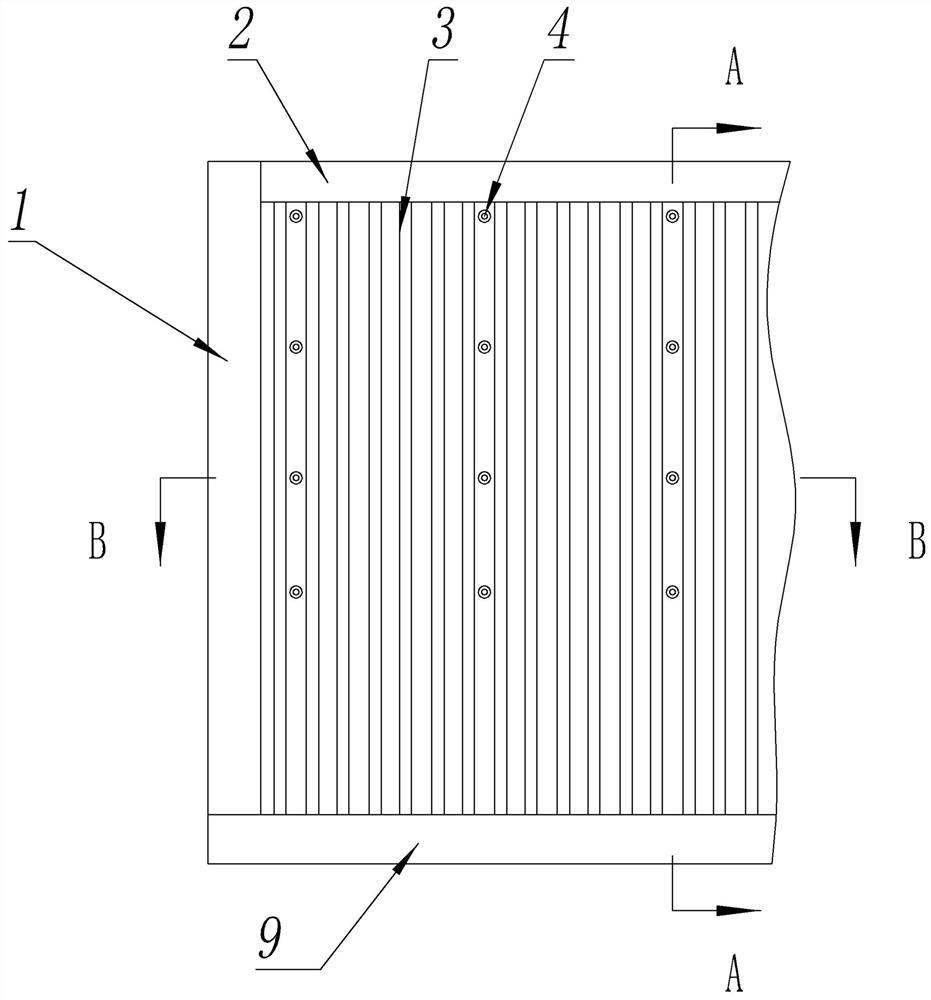

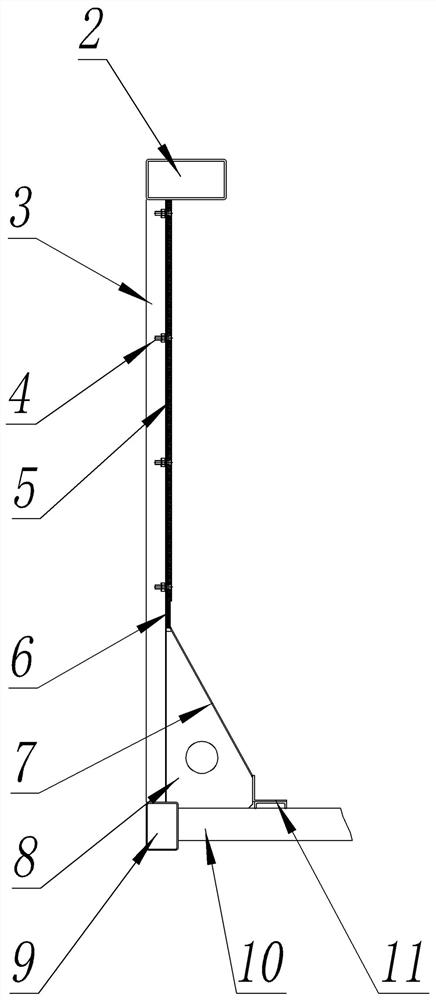

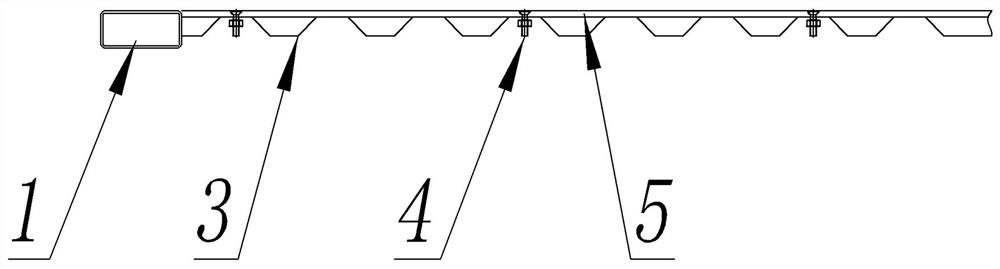

[0014] Such as Figure 1-4 As shown, a schematic diagram of the overall structure of the compartment with a liner of the present invention is provided. The shown compartment includes a compartment column 1, an upper side beam 2, a lower side beam 9 and a frame beam 10, and the upper side beam 2 and the front and rear ends of the side rail 9 are respectively fixed on the upper and lower ends of the carriage column 1 at the front and rear ends of the carriage, the frame beam 10 is respectively fixed between the lower ends of the carriage pillar 1 at the left and right ends of the carriage, and the upper side beams 2 on the left and right sides The outside between the lower side beam 9 is fixed with an outer box plate 3, and the outer box plate 3 is set to a corrugated type, and the corrugated type box plate increases the overall strength of the compartmen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com