Rail-hanging fire-fighting inspection robot

A patrolling robot and fire-fighting technology, applied in manipulators, fire rescue, manufacturing tools, etc., can solve the problems of high investment cost, limited fire extinguishing range, and inability to replace fire extinguishing bags by itself, and achieve the effect of reducing construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

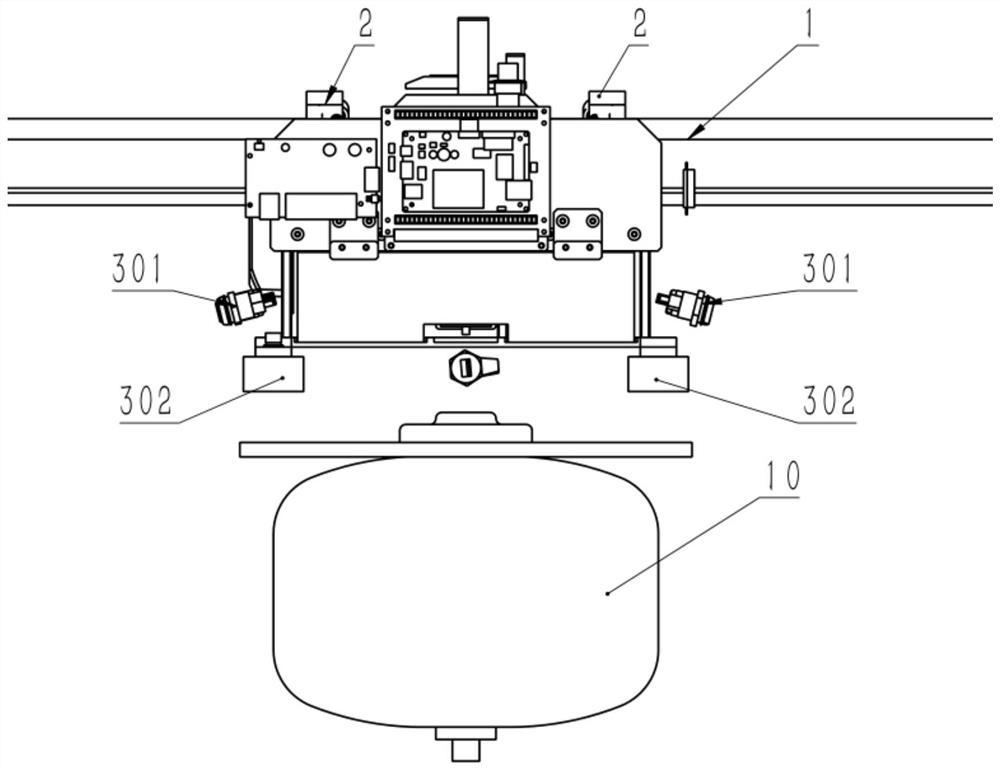

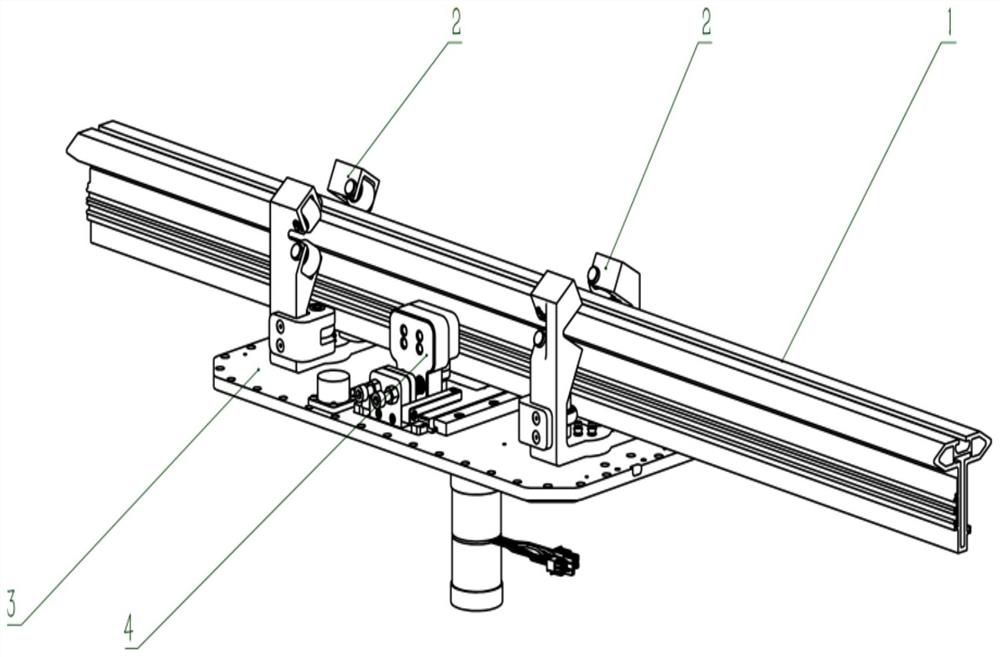

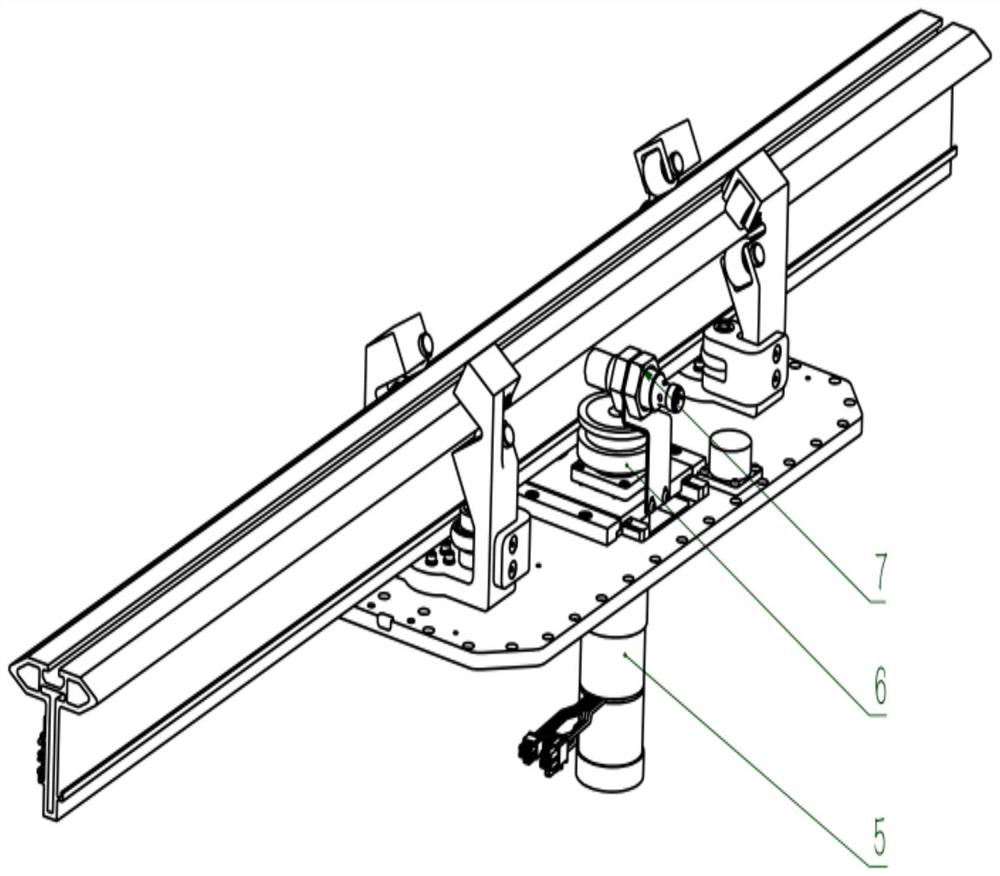

[0023] see Figure 1-7 , the present invention provides a technical solution: a rail-mounted fire inspection robot, including a track module 1, the side wall of the track module 1 is slidably provided with a symmetrical driven wheel mechanism 2, and the lower ends of the two driven wheel mechanisms 2 are fixed together There is a traveling mechanism frame 3, and the front end of the upper side wall of the traveling mechanism frame 3 is fixedly provided with a slide rail line collector and a pressure wheel 4, and the slide rail line collector and pressure wheel 4 are slidingly connected with the front side wall of the track module 1, and the traveling mechanism The lower side wall of the frame 3 is fixedly provided with a motor 5, the rear end of the upper side wall of the traveling mechanism frame 3 is fixedly provided with a drive wheel 6, and the upper end of the drive wheel 6 is fixedly provided with an RFID reader-writer 7, and the RFID reader-writer 7 and the track The re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com