Method for making yoghourt by using air fryer

An air fryer and yogurt technology, applied in applications, dairy products, household appliances, etc., can solve problems such as high heating temperature, failure to ferment normally, and inability to make yogurt food

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

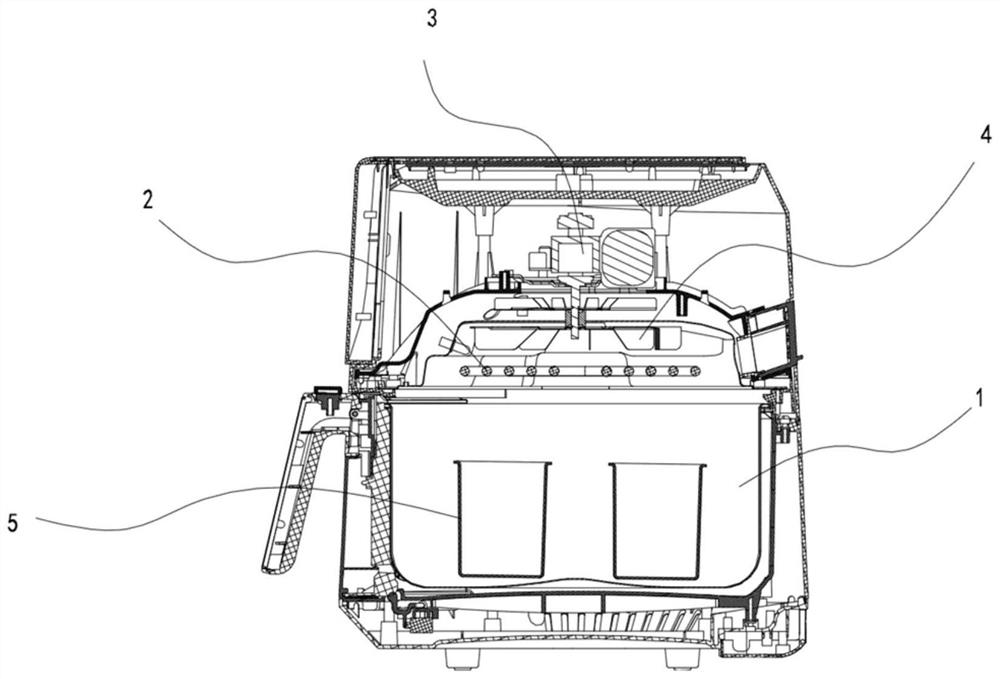

Embodiment 1

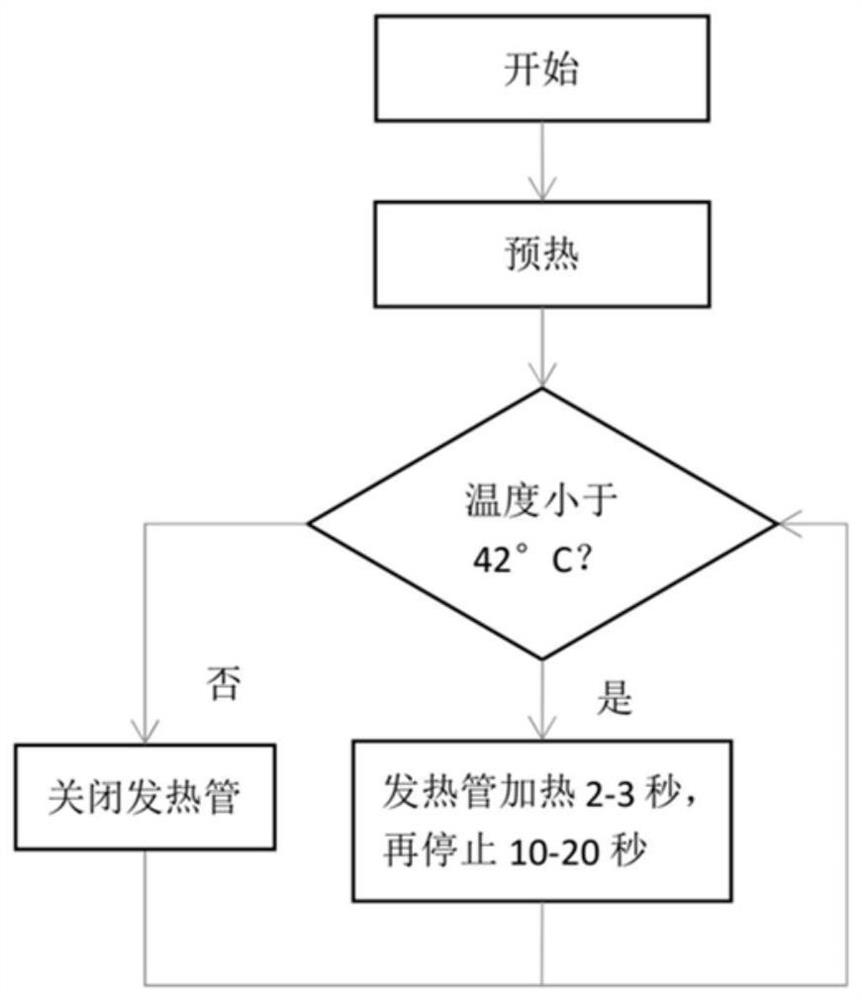

[0035] Set T0 as the suitable temperature of 42°C for the fermentation of lactic acid bacteria in yogurt 5, and the heating element 2 is a heating tube arranged on the top of the cooking chamber 1 and below the fan 4. Considering that the power of the heating tube of the air fryer is generally as high as 1000- 1500W, at the same time, the cooking cavity is a relatively closed cavity. When the heating tube is turned on, the temperature rise will be very fast. 1 / 5-1 / 10, such a power will not cause the temperature in the cooking cavity 1 to change too fast, and can further reduce the temperature range.

[0036] The specific steps for the intermittent heating method for the heating tube are: open the heating tube, heat for 2-3 seconds, then close the heating tube, stop heating for 10-20 seconds; use this as a cycle for continuous intermittent heating, this Both the heating time and the intermittent time can be determined according to the characteristics of the heating element 2 . ...

Embodiment 2

[0040] This embodiment is similar to Embodiment 1, the difference is that before the fan is turned off, the initial temperature of the cooking chamber 1 in this embodiment is at normal temperature, so it is necessary to preheat the cooking chamber 1, and start the fan at the same time during preheating 4 and the heating tube, so that the temperature T in the cooking cavity 1 rises rapidly to a certain temperature, then turn off the fan 4, and control the working condition of the heating tube according to the detected temperature T in the cooking cavity, and use intermittent heating to make the cooking cavity The temperature T inside reaches the temperature 42 ℃ suitable for lactic acid bacteria fermentation. By means of preheating, the inside of the cooking cavity reaches an appropriate high temperature first, and then the heating element is controlled to adopt the intermittent heating method, so that the temperature can be changed in a small temperature range, and can be maint...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com