Visual counting and packaging all-in-one machine

An all-in-one machine and visual technology, applied in packaging, transportation packaging, packaging protection, etc., can solve the problems of inaccurate material quantity, high manual labor intensity, low efficiency, etc., and achieve reduced material overlap, good feeding stability, and high feeding efficiency high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the embodiments and accompanying drawings, and the contents mentioned in the embodiments are not intended to limit the present invention.

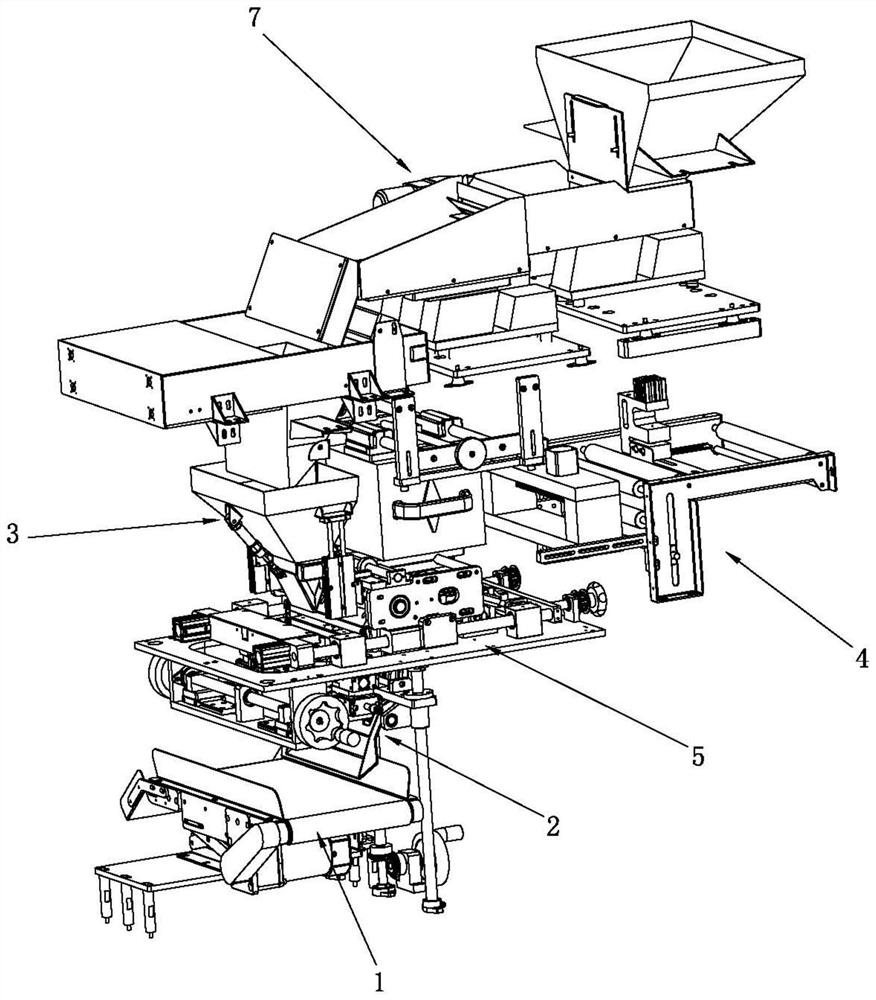

[0035] like Figure 1 to Figure 18As shown, a visual counting and packaging integrated machine provided by the present invention includes a machine platform, a tube film feeding device 4 arranged on the machine platform, and a bag opening, cutting and sealing integrated device 5 arranged at the discharge end of the tube film feeding device 4 , the material supporting device 2 located below the bag opening, cutting and sealing integrated device 5, the bagging device 3 located above the bag opening, cutting and sealing integrated device 5, and the precision feeding device 7 located above the bagging device 3, so The precise feeding equipment 7 includes a feeding funnel 71, a first feeding mech...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com