Preparation method of low-smoke halogen-free flame-retardant cable material

A cable material and raw material technology, applied in the field of cable raw material preparation, can solve the problems of increasing particle load, difficulty in rapid drying, lack of strength and anti-deformation performance, etc., to achieve the effect of improving strength and anti-deformation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

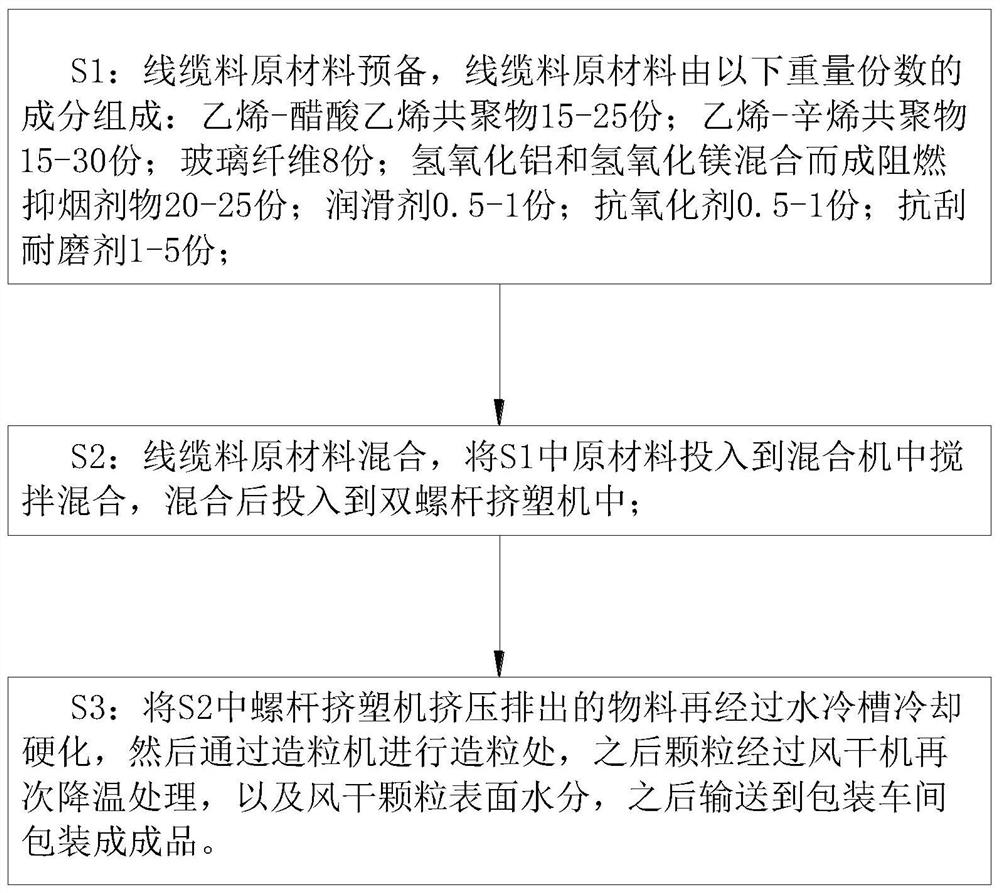

[0028] refer to Figure 1-Figure 3 Shown, the preparation method of low-smoke halogen-free flame-retardant cable material, its preparation method comprises the following steps:

[0029] S1: Preparation of cable material raw materials. The cable material raw materials are composed of the following components in parts by weight: 15-25 parts of ethylene-vinyl acetate copolymer; 15-30 parts of ethylene-octene copolymer; 8 parts of glass fiber; 20-25 parts of flame retardant and smoke suppression agent mixed with aluminum and magnesium hydroxide; 0.5-1 part of lubricant; 0.5-1 part of antioxidant; 1-5 parts of anti-scratch and wear-resistant agent; Improve the strength and deformation resistance of the cable;

[0030] S2: mixing the raw materials of the cable material, putting the raw materials in S1 into the mixer for stirring and mixing, and putting them into the twin-screw extruder after mixing;

[0031] S3: The material extruded by the screw extruder in S2 is cooled and harde...

Embodiment approach

[0032] As an embodiment of the present invention, in the S2, the raw materials of the cable material are mixed and stirred, and the counterclockwise and clockwise directions of the mixer are alternately stirred; the counterclockwise and clockwise directions of the mixer are alternately stirred, so that the glass fibers swim irregularly , so that the glass fibers are intertwined with each other, and the glass fibers play a supporting role, thereby improving the strength and deformation resistance of the cable.

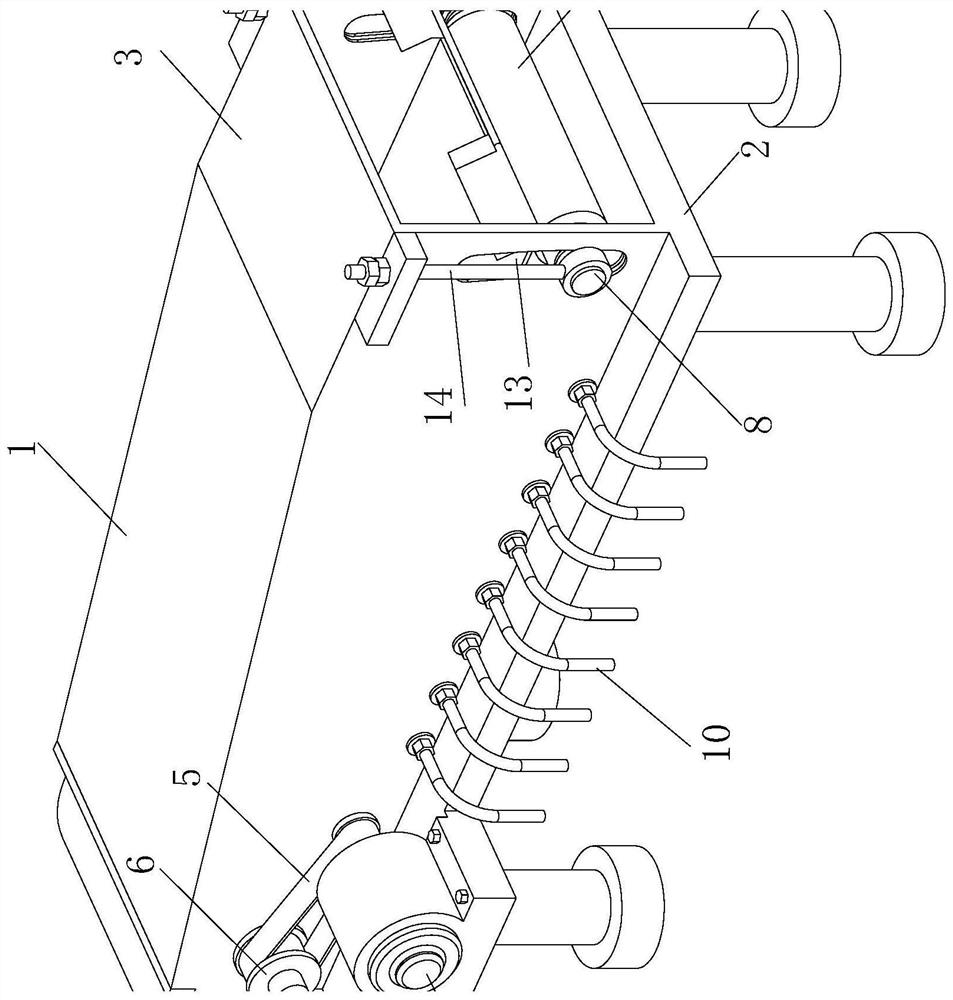

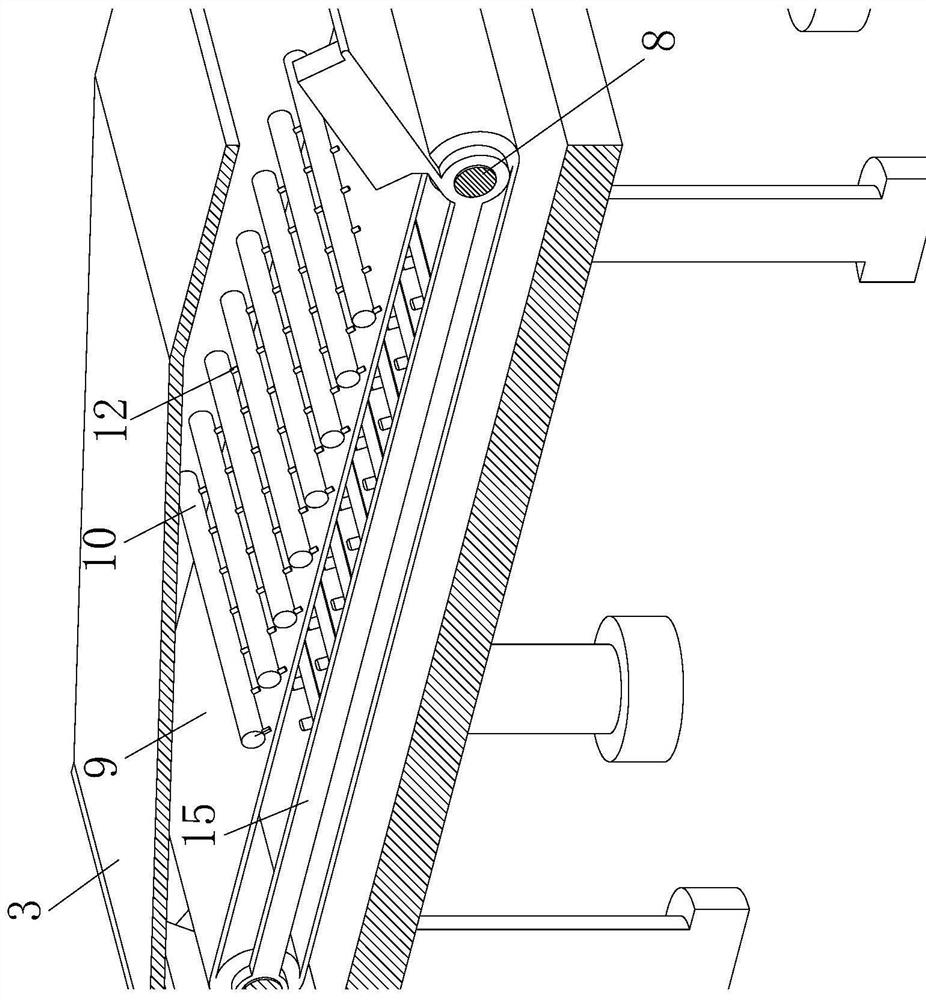

[0033]As an embodiment of the present invention, the air dryer 1 used in the S3 includes a workbench 2; the workbench 2 is provided with a ventilation housing 3, a transfer unit and an air-drying unit; the ventilation housing 3 is affixed to The workbench 2, the transmission unit is arranged between the ventilation housing 3 and the workbench 2; the transmission unit includes a motor 4, a belt 5, a pulley 6, a driving shaft 7, a driven shaft 8 and a conveyor belt 9; the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com