Floor treatment machine

A floor and machine technology that is used in floor treatment machines to solve problems such as operator fatigue, not very suitable for straight line movements, and it is difficult for the machine to make sharp turns to get around corners or obstacles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

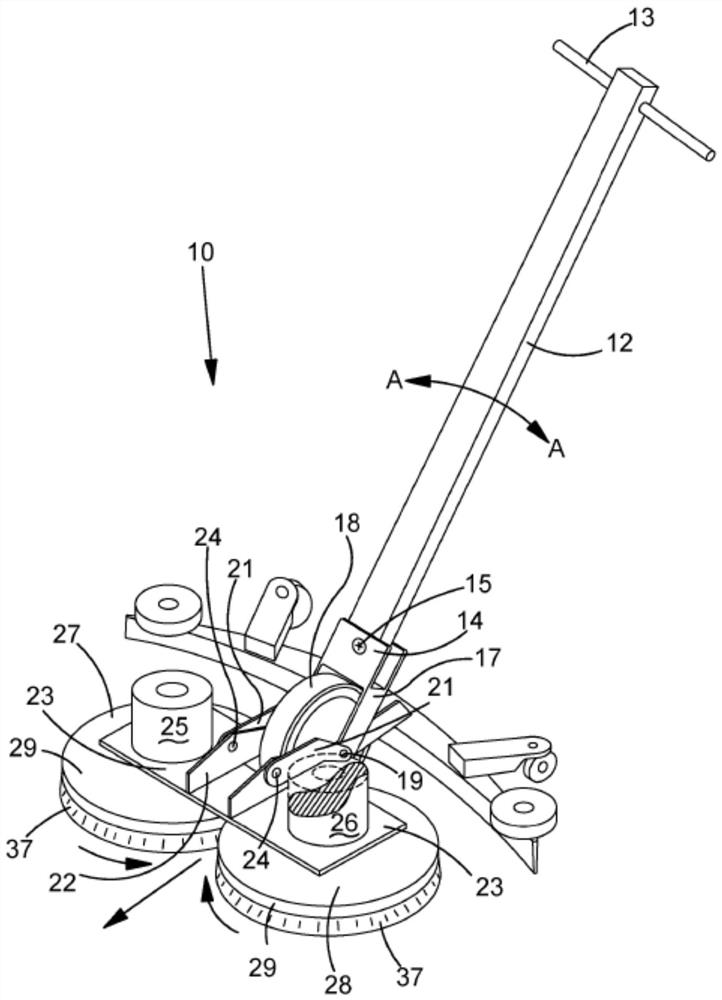

[0024] exist figure 1 In the figure, a floor scrubbing dryer according to the present invention is shown generally at 10 . The machine comprises a handle portion 12 of elongated rectangular section. The handle portion 12 includes a top end region and a bottom end region. A handle 13 is mounted transversely to the top end region of the handle portion 12 through a hole. A control unit (not shown) is also provided at the tip area. During use, the user walks behind the machine and uses the handle 13 to guide it onto the floor surface to be cleaned.

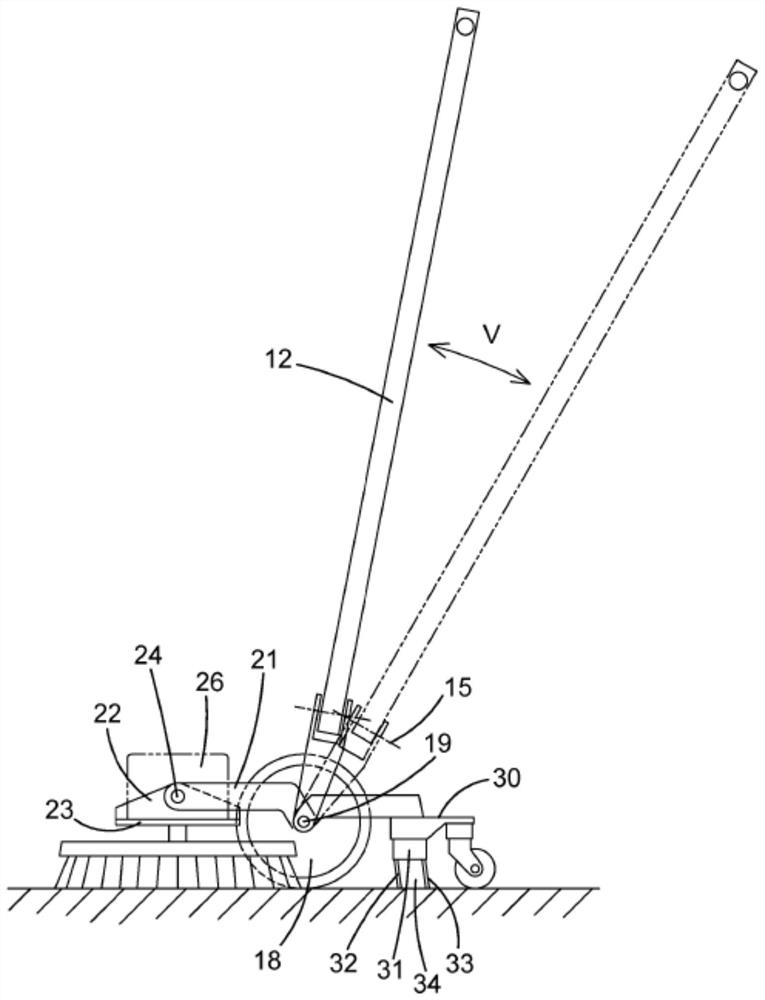

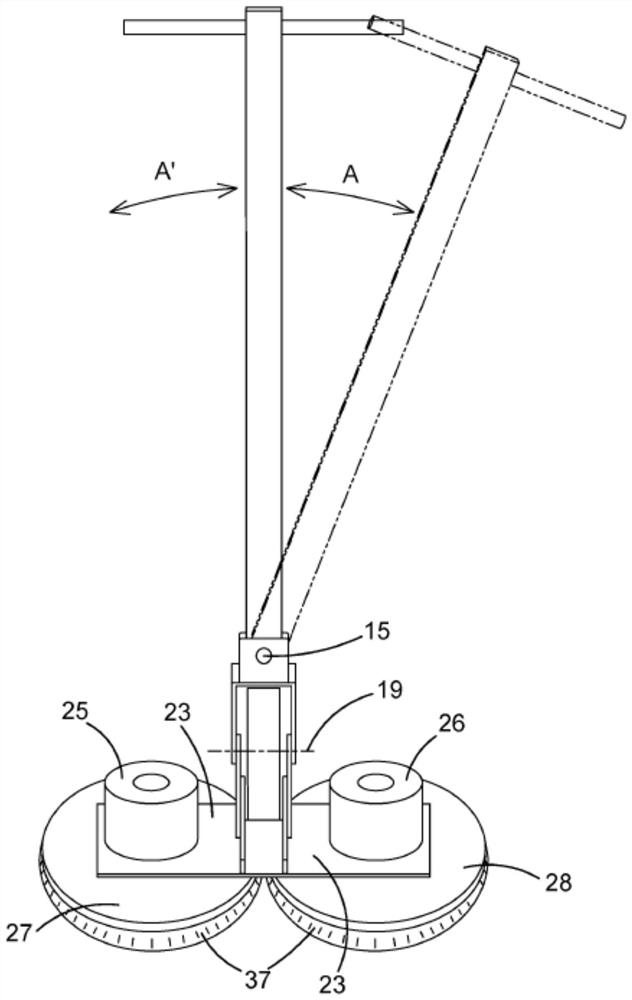

[0025] The bottom end region of the handle portion 12 is pivotally attached between upstanding ears of a U-section mounting bracket 14 . The pivot is oriented forward and backward so that the handle portion is about the pivot axis 15 relative to the bracket 14 (eg image 3 Shown by arrows A, A') can be rotated side to side. This axis 15 is substantially perpendicular to the length of the handle part 2 and allows lateral side-to-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com