Rice production packaging system based on intelligent control

An intelligent control, rice technology, applied in the direction of packaging automatic control, packaging, packaging protection, etc., can solve the problems of inability to intelligently clean up impurities, inaccurate measurement, poor storage environment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

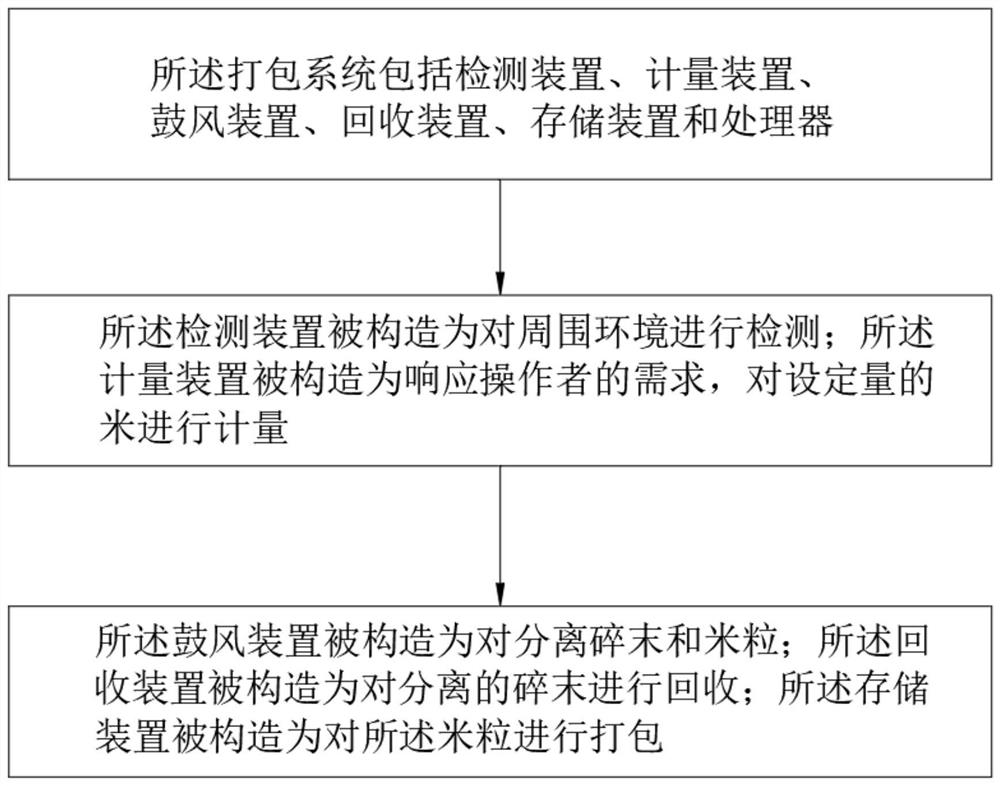

[0035]Embodiment 1: A kind of rice production packing system based on intelligent control, described packing system comprises detection device, metering device, blower device, reclaiming device, storage device and processor, and described detection device is configured to monitor the surrounding environment detection; the metering device is configured to measure a set amount of rice in response to the needs of the operator; the blower device is configured to separate the broken powder and rice grains; the recovery device is configured to separate the broken rice Recycling at the end; the storage device is configured to pack the rice grains;

[0036] Optionally, the detection device includes several display chambers, a material taking mechanism and a feeding mechanism, and the material taking mechanism and the feeding mechanism are correspondingly arranged in each of the display chambers, and the material taking mechanism is configured as Retrieving the rice stored in the stora...

Embodiment 2

[0041] Embodiment 2: Usually, the milled rice is collected in a container connected to the rice, and then the user takes out the milled rice by himself; in this way, it brings inconvenience to the user and cannot fully satisfy the user. At the same time, due to the small diameter of the end of the rice, the rice is prone to fragmentation during transportation; compared with the intact rice, the particle size of the fragmented rice is relatively small, and the time required for cooking is relatively short , that is, in the case of the same cooking time, if the broken rice is mixed with the whole rice, the broken rice will be overcooked and soft, which will affect the taste of the rice. The broken rice needs to be removed during packaging; in addition, there are common problems such as inaccurate measurement, poor storage environment, low degree of automation, and inability to intelligently clean impurities;

[0042] Provide a kind of rice production packing system based on inte...

Embodiment 3

[0049]Embodiment 3: This embodiment should be understood as at least including all the features of any one of the foregoing embodiments, and further improved on the basis of it; a kind of rice production packing system based on intelligent control is provided, and the packing system includes a detection device , a metering device, a blower device, a recovery device, a storage device and a processor, the detection device is configured to detect the surrounding environment; Metering; the blowing device is configured to separate the broken powder and rice grains; the recovery device is configured to recover the separated broken powder; the storage device is configured to pack the rice grains; the detection device It is used to detect the range of activities of people. When there are task activities around the whole system, it will trigger the display of rice samples, which changes the traditional situation of rice samples being exposed in the storage tank; the condition of rice st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com