Sandstone screening equipment for building construction

A technology for construction and screening equipment, which is applied in the direction of filter screen, solid separation, grille, etc. It can solve the problems of screen blockage, large-size sand and gravel that cannot be effectively used, and large-size sand and gravel that cannot be crushed and processed. Achieve the effect of solving easy blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

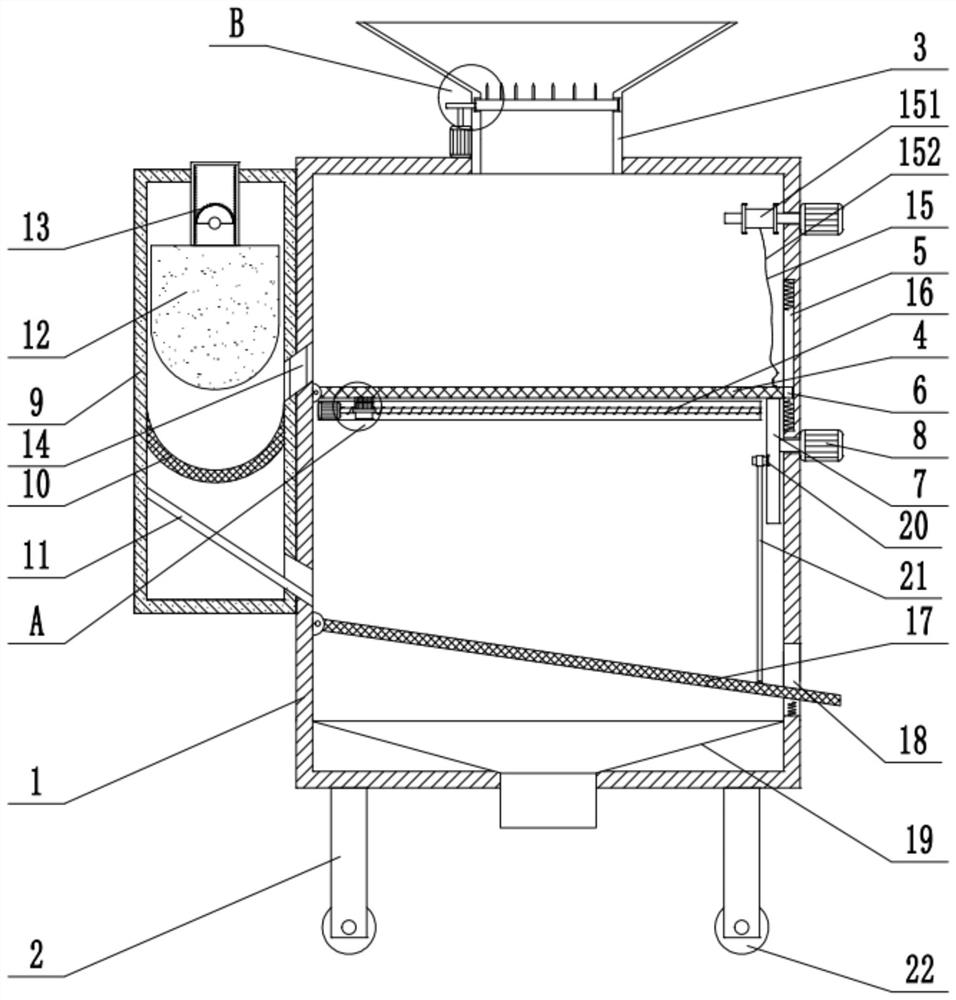

[0025] see Figure 1-5 , a kind of sand and gravel screening equipment for building construction, comprising a box body 1, supporting legs 2 are fixedly installed around the bottom of the box body 1, and a feeding funnel 3 extending to the inside of the box body 1 is fixedly installed on the top of the box body 1, and the box body 1. The first filter plate 4 is installed on the inner left wall. The right wall of the box body 1 is provided with a vertical groove 5. A slider 6 fixedly connected to the right side wall of the first filter plate 4 is slidably installed in the vertical groove 5. The box body 1. A motor 8 is fixedly installed on the right side wall. The output shaft of the motor 8 extends into the box body 1 and a cam 7 close to the right bottom wall of the first filter plate 4 is fixedly installed. The box body 1 on the left side of the first filter plate 4 The side wall is provided with a first discharge port 14, and the left side wall of the box body 1 is fixedly ...

Embodiment 2

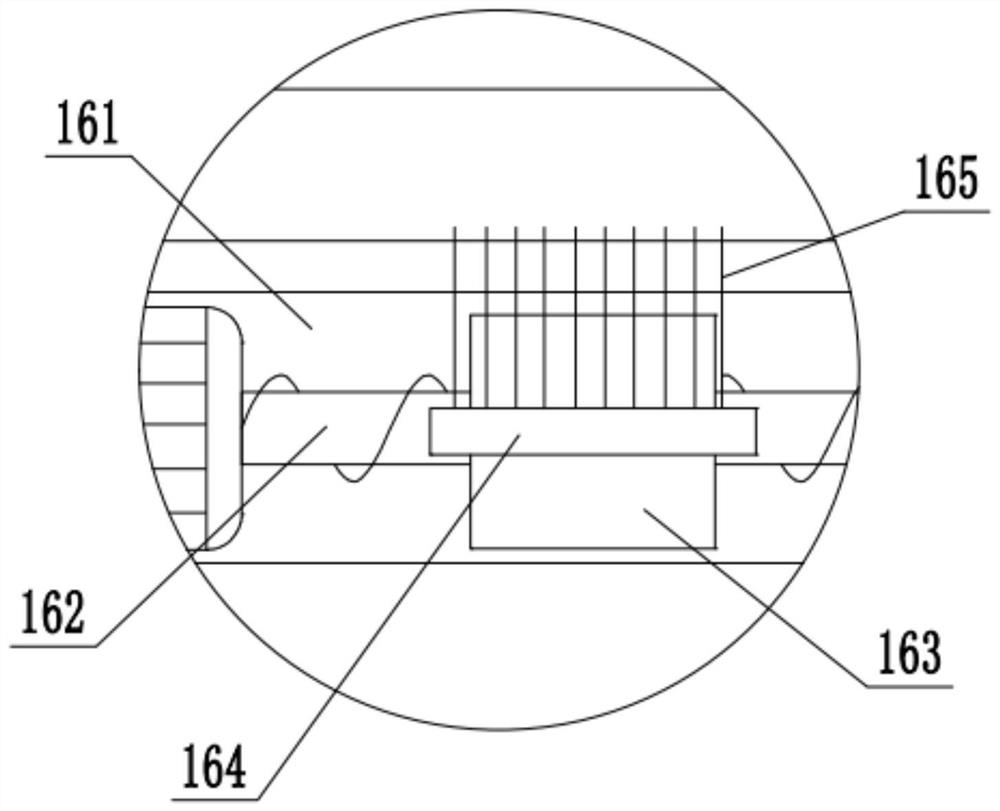

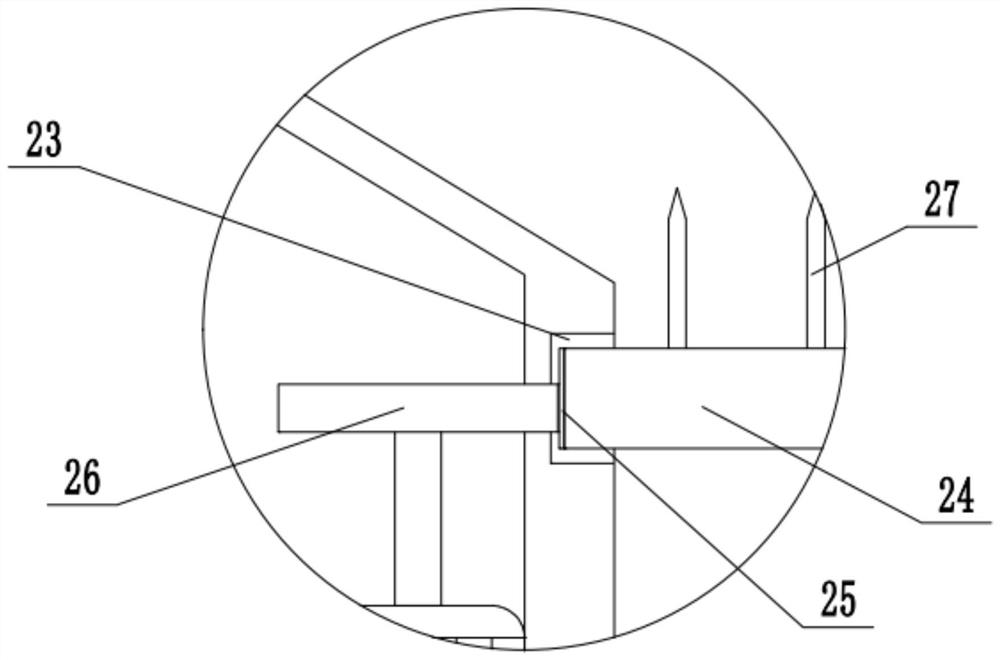

[0027]On the basis of Embodiment 1, an annular groove 23 is provided on the circumferential inner wall of the feeding funnel 3, and a blanking plate 24 is slidably installed in the annular groove 23, and a toothed ring 25 is fixedly installed on the circumferential side wall of the blanking plate 24, and the box body 1. A motor 8 is fixedly installed on the top, and the output shaft of the motor 8 is fixedly installed with a gear plate 26 meshed with the gear ring 25. The top of the blanking plate 24 is fixedly installed with multiple groups of stirring cones 27 distributed at intervals from the blanking holes. The disc 26 meshes with the gear ring 25 to drive the lower material plate 24 to rotate and cooperate with the stirring cone 27 to effectively control the falling speed of the sand and prevent the sand from being blocked in the feeding funnel 3. The vibrating part 13 includes a vibrating The U-shaped frame 131 that is fixedly installed upwards on the top of the smashing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com