Fruit picking robot

A technology for picking robots and fruits, applied in picking machines, harvesters, agricultural machinery and implements, etc., can solve problems such as affecting the quality of fruit picking, affecting picking efficiency, and pulp damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

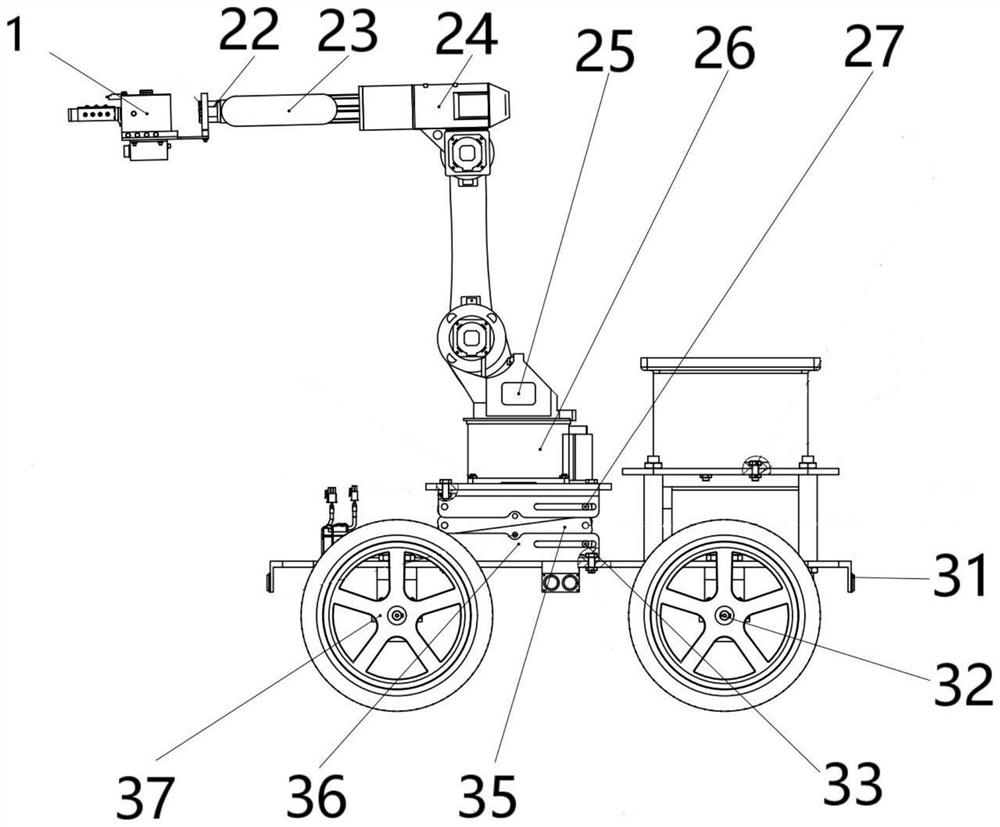

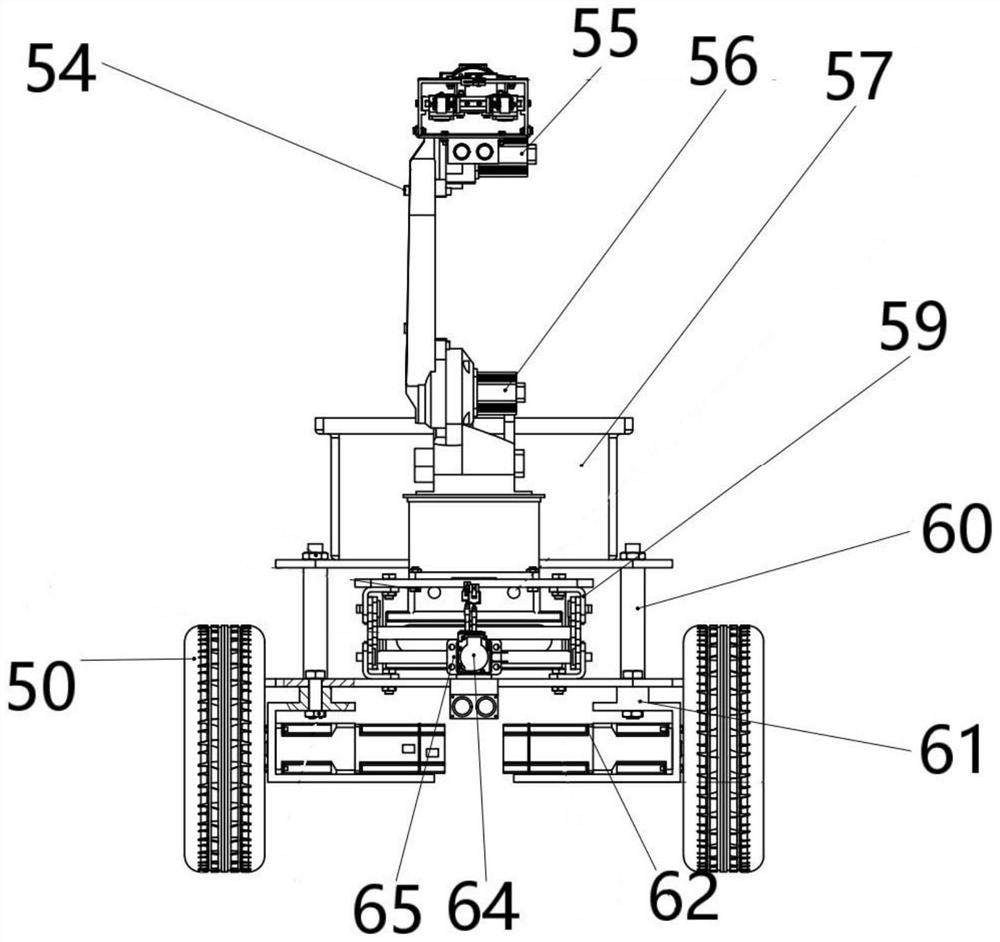

[0035] see Figure 1-Figure 3 , this embodiment discloses a fruit picking robot, comprising a walking chassis, a picking execution device arranged on the walking chassis for picking fruit, and a picking execution device arranged between the walking chassis and the picking execution device for adjusting the height of the picking execution device The lifting device and the fruit collecting device arranged on the walking chassis for collecting fruits.

[0036] see Figure 1-Figure 5 , the picking execution device includes an end effector and a mechanical arm arranged between the end effector and the lifting device for driving the end effector to perform multi-degree-of-freedom movements on the lifting device; the end effector includes a mounting frame arranged on the mechanical arm, a fruit stem clamping mechanism disposed on the front end of the mounting frame for clamping the fruit stem, and a cutting mechanism disposed above the fruit stem clamping mechanism for cutting the f...

Embodiment 2

[0065] Other structures in this embodiment are the same as in Embodiment 1, the difference is that the scissor lifting mechanism is a two-stage scissor lifting mechanism, and two first scissors and two second scissors are connected up and down. , its specific structure refers to the prior art. By setting the two-stage scissor lifting mechanism, the height adjustment range can be improved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com