Separable mining permanent magnet synchronous frequency conversion and speed regulation all-in-one machine motor structure

A permanent magnet synchronous and variable frequency speed regulation technology, which is applied in the direction of connecting with the control/drive circuit, etc., can solve the problems of reduced system reliability, inconvenient maintenance and replacement, etc., and achieves the effect of improving reliability, easy maintenance, and compact structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

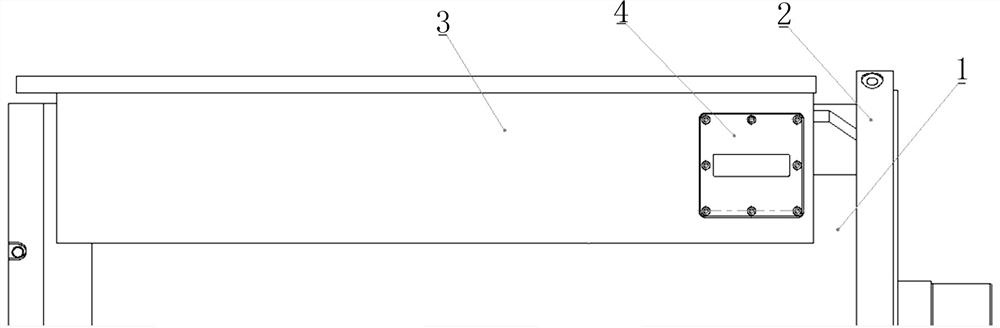

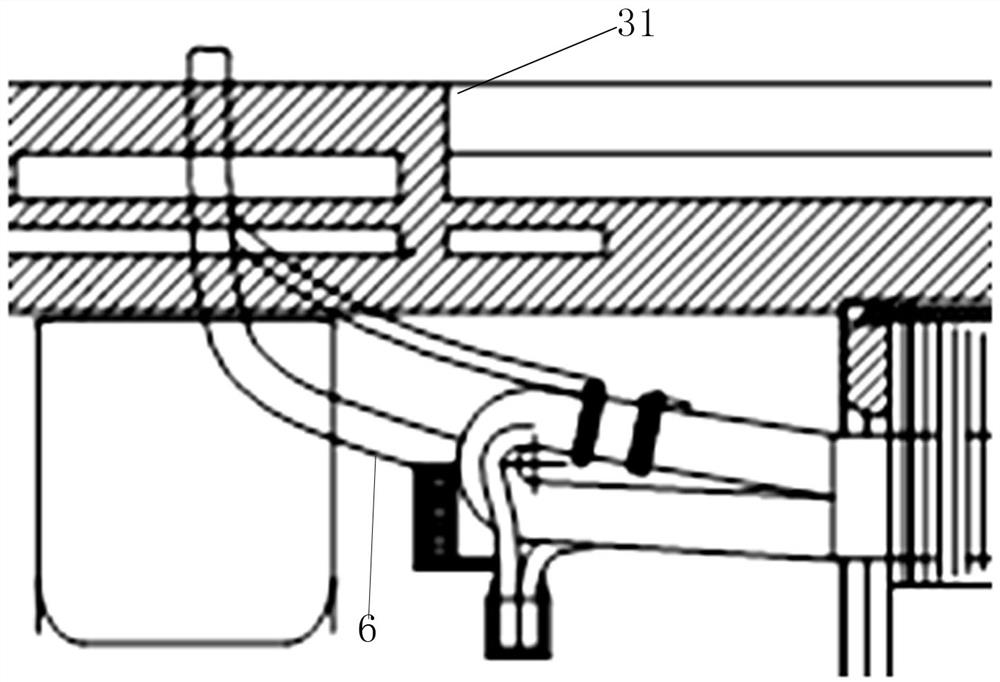

[0040] A detachable mine-used permanent magnet synchronous frequency conversion and speed regulation integrated machine motor structure, including a motor case, a frequency converter connection base 3 is installed on the top of the motor case 1, and a frequency converter and wiring are installed in the frequency converter connection base 3 Terminal 5, wherein the connection between the frequency converter and the frequency converter connection base 3 adopts a movable detachable connection; the bottom of the terminal 5 has a hole through the inside of the motor casing 1 (the connection base of the frequency converter corresponding to the bottom of the connection terminal and the motor machine There are holes on the shell); the frequency converter assembly is installed in the frequency converter connection base 3, and the motor three-phase connection wire extends from the inside of the motor casing to the frequency converter connection base and is directly connected to the output ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com