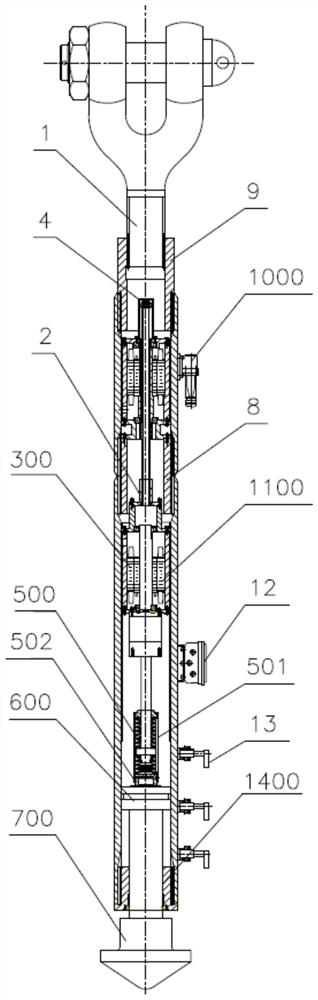

Windproof tie rods with electric telescopic and twist lock

An electric retractable and twist-lock technology, which is applied in the directions of transportation and packaging, load suspension components, and traveling mechanisms, can solve problems such as time-consuming, labor-intensive, long adjustment time, and incompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

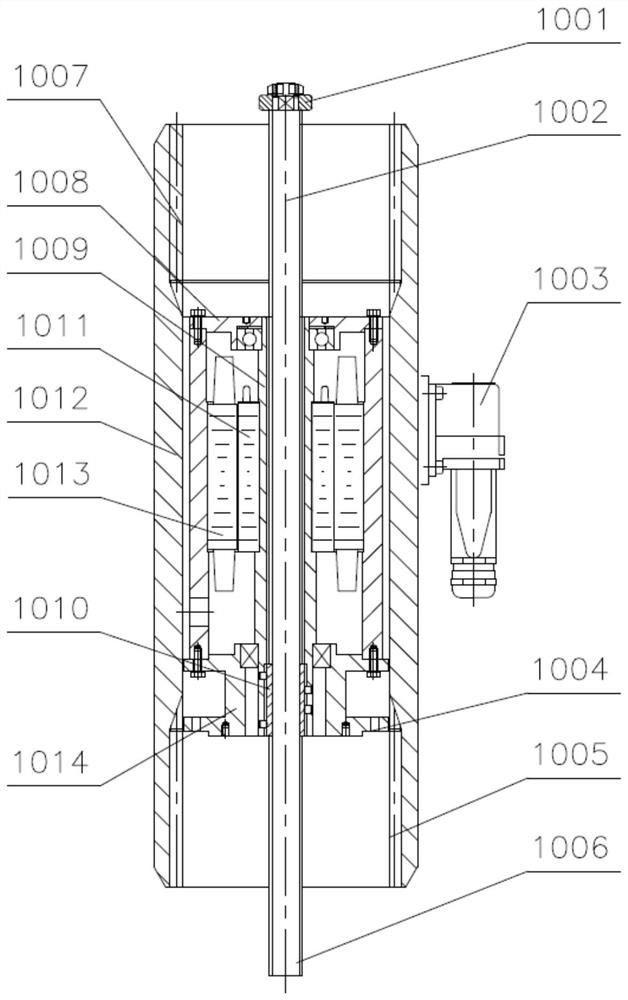

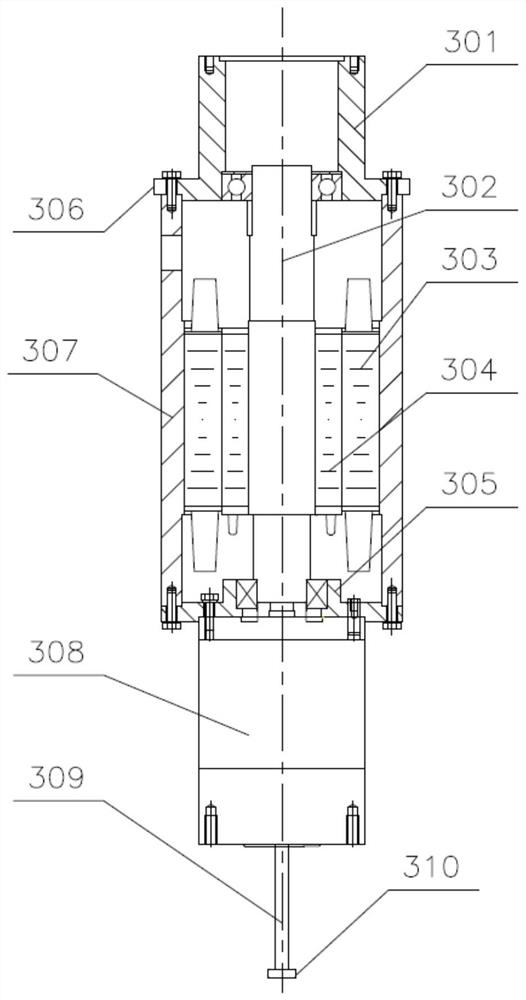

[0055] Example 1, when the ground anchor is open in the running direction of a large mechanical cart (the lock head shaft telescopic motor 1000 works, and the lock head rotation deceleration motor 300 does not work):

[0056] The large-scale machinery of the container terminal is positioned by the induction limit or the encoder, and walks to the side of the anchoring position; the lock shaft telescopic motor 1000 in the embodiment of the present invention is activated, and the motor shaft 1009 drives the nut 1010 in the shaft hole to rotate, and drives the telescopic screw shaft 1002 moves down, drives the rotary motor 300 to slide down together, and makes the lock head of the lock head shaft 700 drop vertically to the middle of the ground anchor seat lock body through the buffer coupling 500, and the lock head of the lock head shaft 700 rotates to lock the hook anchor. When the surface 705 is lower than the hooking surface of the lock body of the anchor seat, the telescopic mo...

Embodiment 2

[0058] Embodiment 2, when the ground anchor is plug-in:

[0059] The large-scale machinery of the container terminal is positioned by the induction limit or the encoder, and walks to the top of the insertion hole at the anchoring position; the lock shaft telescopic motor 1000 in the embodiment of the present invention is activated, and the motor shaft 1009 drives the nut 1010 in the shaft hole to rotate, driving the telescopic wire The rod shaft 1002 moves downward, driving the rotary motor 300 to slide down together, and through the buffer coupling 500, the lock head of the lock head shaft 700 is vertically lowered and inserted into the middle of the ground anchor seat lock body. The lock head hook of the lock head shaft 700 When the anchor surface 705 is lower than the hooking surface of the anchor seat lock body, the lock shaft telescopic motor 1000 automatically stops according to the position information detected by the position sensor 13; 500 rotates the lock head of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com