Layered canning equipment for Taihe black-bone stewed soup cans

A black-bone chicken pot and layered technology, which is applied in the field of layered canning equipment for Taihe black-bone chicken pot cans, can solve the problems of inconsistent canning quality, easy precipitation of silky chicken pot, and difficulty in ensuring uniform canning, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

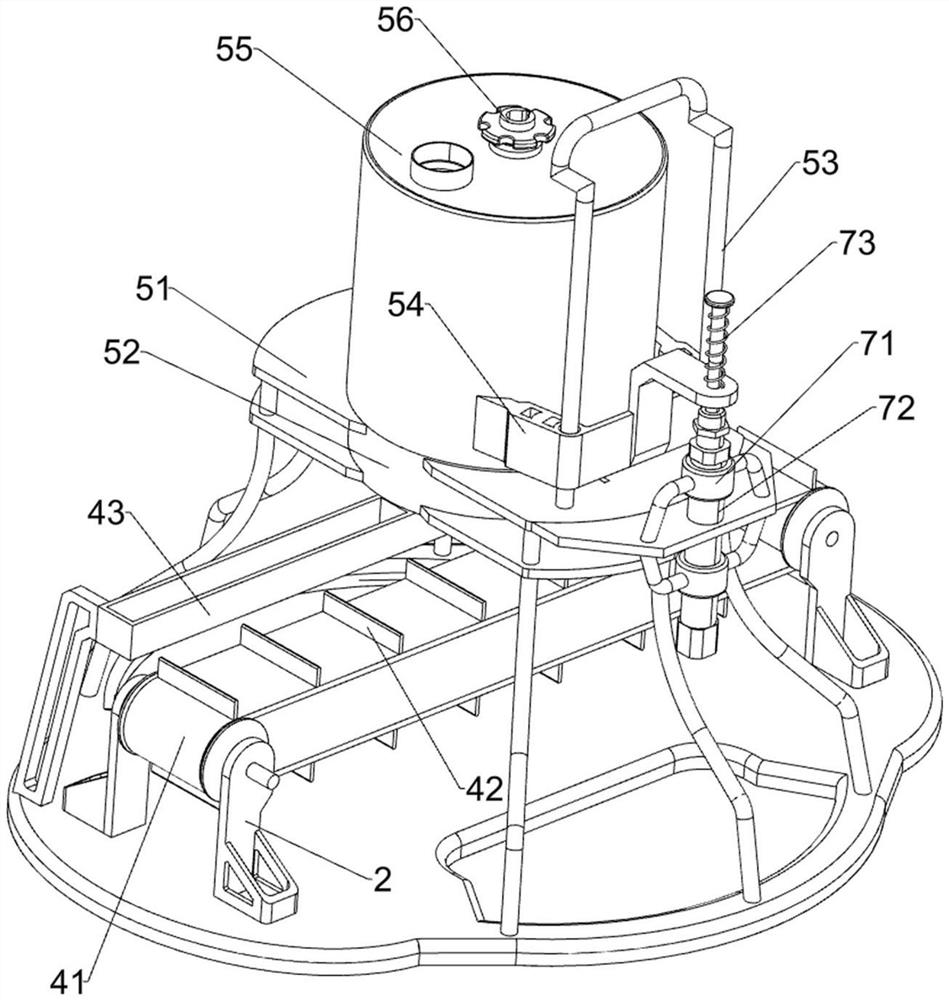

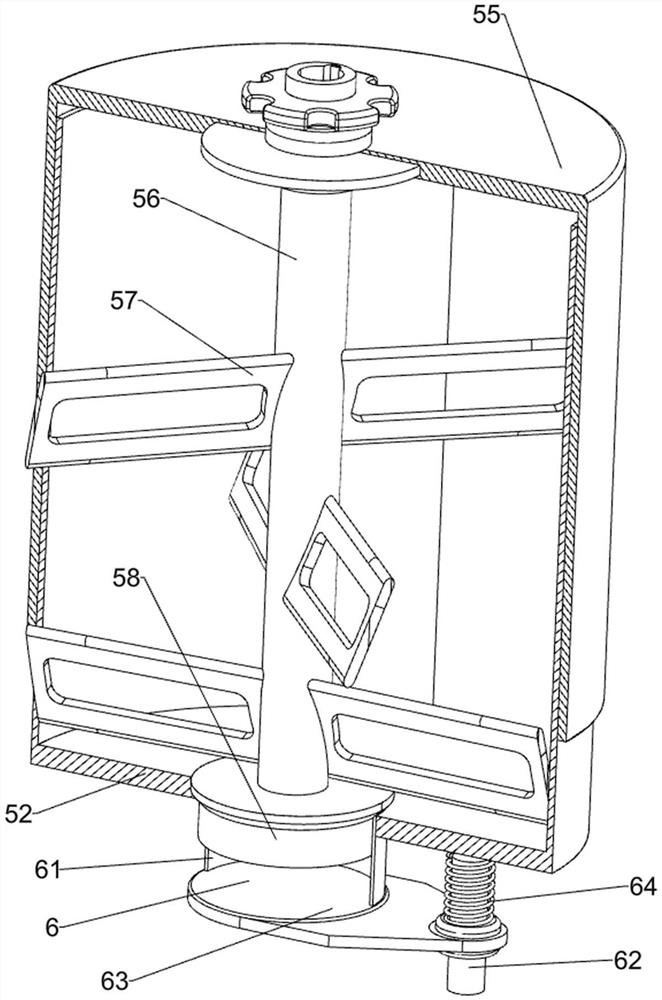

[0028] A kind of layered canning equipment for Thai and silky chicken pot cans, such as Figure 1-3 As shown, it includes a base 1, a mounting base 2, a conveying assembly 4, a material storage assembly 5, a feeding assembly 6 and a lifting assembly 7. The top left and right sides of the base 1 are connected with the mounting base 2, and the base 1 and the mounting base 2 A conveying assembly 4 is connected between them, a storage assembly 5 is installed on the top of the base 1, the storage assembly 5 is located above the conveying assembly 4, and a blanking assembly 6 and a lifting assembly 7 are connected to the storage assembly 5.

[0029] The conveyor assembly 4 includes a conveyor belt 41, a partition 42 and a limit plate 43, a conveyor belt 41 is connected between the mounting seats 2 on both sides, and a partition 42 is evenly spaced on the conveyor belt 41. Limiting plates 43 are connected to both sides, and the limiting plates 43 on both sides are respectively locate...

Embodiment 2

[0035] On the basis of Example 1, such as Figure 4Shown, also include rotating assembly 8, rotating assembly 8 includes first connecting rod 81, contact plate 82, mounting plate 83, shaft rod 84, disk 85, connecting plate 86 and bevel gear 87, cylinder 72 telescoping rod The top is connected with a first connecting rod 81, the front side of the mounting frame 51 is slidably connected with a contact plate 82, the top of the contact plate 82 is connected with the first connecting rod 81, the bottom of the mounting frame 51 is connected with a mounting plate 83, the mounting plate 83 is rotatably connected with shaft rod 84, and the front end of shaft rod 84 is connected with disc 85, and is connected with connecting plate 86 on the disc 85, and connecting plate 86 cooperates with contact plate 82, and the rear end of shaft rod 84 is connected with the first The lower part of the rotating shaft 62 is connected with a bevel gear 87, and the two bevel gears 87 are meshed.

[0036...

Embodiment 3

[0038] On the basis of Example 2, such as Figure 4-5 As shown, a transposition assembly 9 is also included, and the transposition assembly 9 includes a fixed plate 91, a second rotating shaft 92, a one-way gear 93, a second connecting rod 94 and a drive rack 95, and the front left part of the base 1 is connected to There is a fixed plate 91, on which the second rotating shaft 92 is rotatably connected, the front end of the second rotating shaft 92 is equipped with a one-way gear 93, the second rotating shaft 92 is connected with the transmission belt 41, and the end of the first connecting rod 81 A second connecting rod 94 is connected to the upper part, and a driving rack 95 is connected to the lower end of the second connecting rod 94, and the driving rack 95 meshes with the one-way gear 93.

[0039] When the cylinder 72 shortens, it drives the second connecting rod 94 to move downward, and the driving rack 95 moves downward thereupon. The driving rack 95 moves downward to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com