Slide valve structure with function of inhibiting large temperature drift of electro-hydraulic servo valve and adjustment method

An electro-hydraulic servo valve, temperature drift technology, applied in the valve shell structure, valve operation/release device, valve details and other directions, can solve the problem of reducing the temperature drift of the servo valve and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

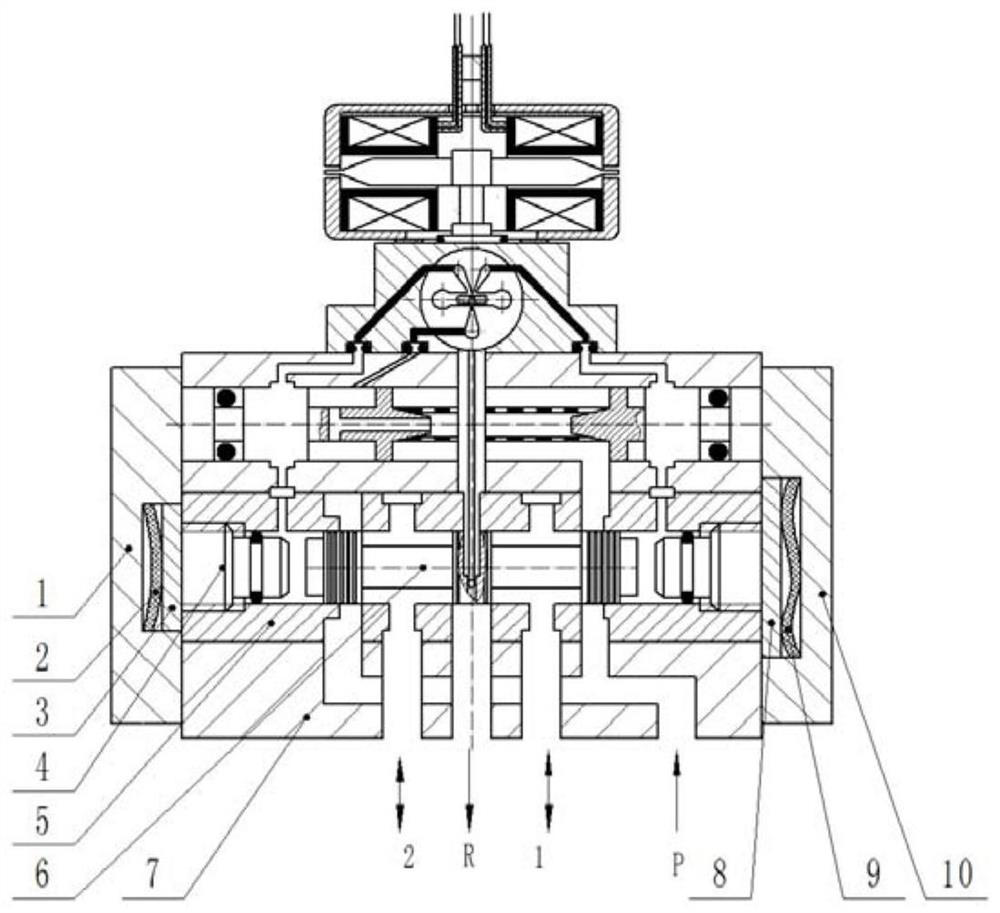

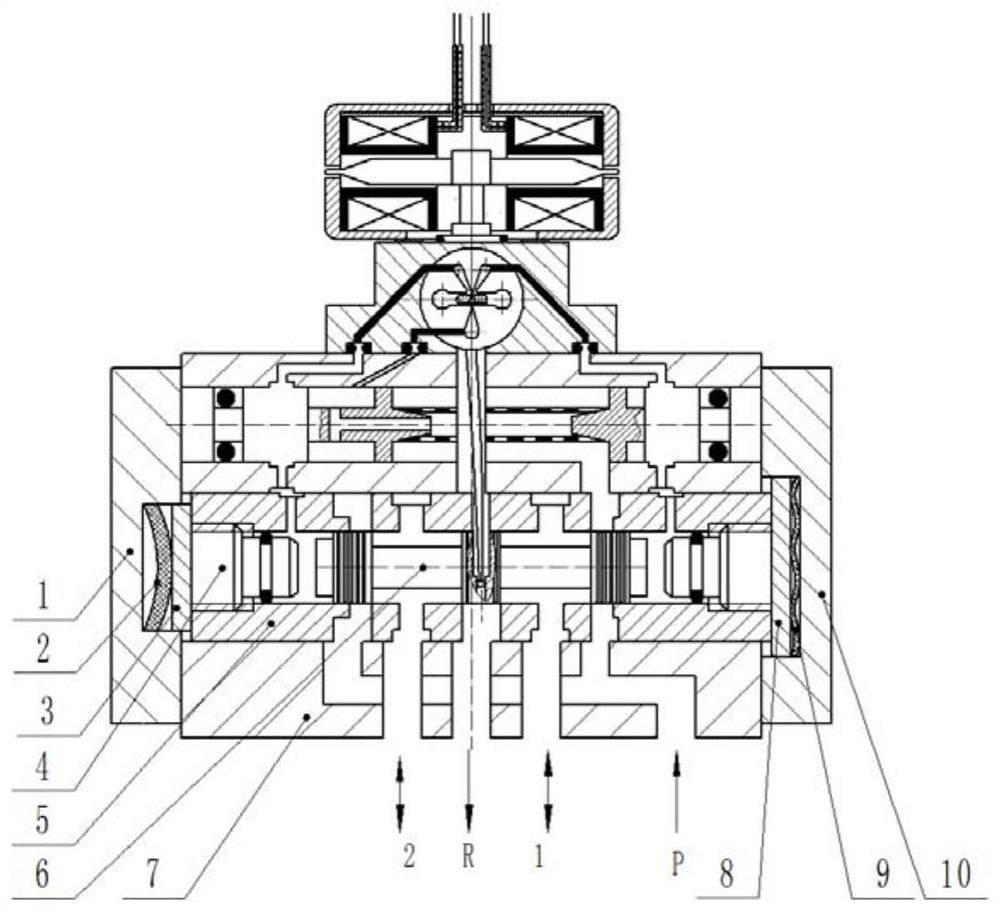

[0042]The present invention provides a sliding valve structure that suppresses the temperature drifting of the electro-hydraulic servo valve, by curved deformation by using a butterfly bimetallic temperature sensitive sheet 2, by temperature adjustment gasket 3 push the valve sleeve 5 The force end cover 10 direction is moved to make the zero position of the spool change with temperature, compensating the biasing jet type two-stage electro-hydraulic servo valve torque motor level and jet flux, which ultimately reduces the warm drift of the entire valve.

[0043]figure 1 It is a schematic diagram of a slight-tension-resistant to a temperature compensated inhibitory electro-hydraulic servo valve that is warm and drifting function to be mounted to the jet deflecting plate electro-hydraulic servo valve. When the temperature of the servo valve is lower than the temperature point required for compensation, the amount of bending deformation of the butterfly-shaped bimetallic temperature sensi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com