A kind of ncm ternary cathode material with surface layer lithium concentration gradient and preparation method thereof

A cathode material and concentration gradient technology, which is applied in the field of NCM ternary cathode material and its preparation, can solve the problems of limited effect and no problem, so as to improve the active lithium content, improve the discharge specific capacity, overcome the discharge specific capacity and Effects of Cyclic Stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A preparation method of NCM ternary positive electrode material with surface layer lithium concentration gradient, comprising the following steps:

[0038] S1, 5mL of citric acid was added to 50mL of solvent, stirred and mixed evenly at 60°C, and the stirring time was 10min to obtain a mixed solution;

[0039] S2, put 20g of NCM ternary cathode material LiNi 0.8 Co 0.1 Mn 0.1 O 2 Join in the mixed solution that S1 obtains, continue to maintain the stirring temperature of 60 ℃, soak time is 10min, obtain suspension;

[0040] S3, S2 gained suspension under reduced pressure suction filtration, obtains solid filter material;

[0041] S4. The solid filter material is placed in a tube furnace, and the temperature is controlled in an oxygen atmosphere for heat treatment at 600°C for 10 hours to obtain an NCM ternary cathode material with a surface lithium concentration gradient.

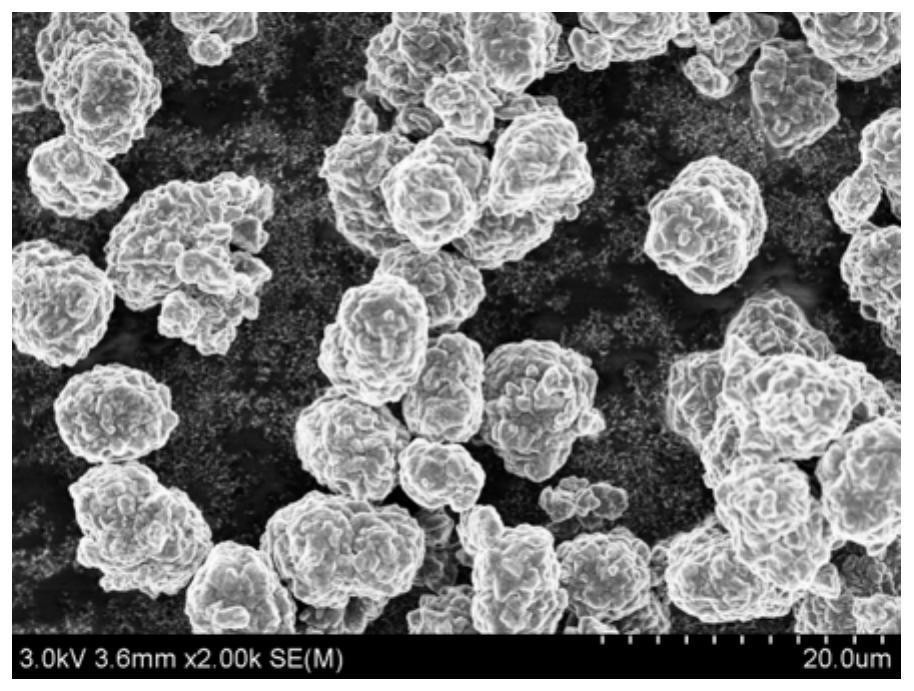

[0042] Scanning electron microscopy results of the final product as figure 1 As can be seen...

Embodiment 2

[0046] A preparation method of NCM ternary positive electrode material with surface layer lithium concentration gradient, comprising the following steps:

[0047] S1, 1mL of maleic acid was added to 50mL of solvent, stirred and mixed at 50°C, and the stirring time was 30min to obtain a mixed solution;

[0048] S2, put 20g of NCM ternary cathode material LiNi 0.8 Co 0.1 Mn 0.1 O 2 Join in the mixed solution that S1 obtains, continue to maintain the stirring temperature of 50 ℃, soak time is 30min, obtain suspension;

[0049] S3, S2 gained suspension under reduced pressure suction filtration, obtains solid filter material;

[0050] S4. The solid filter material is placed in a tube furnace, and the temperature is controlled in an oxygen atmosphere for heat treatment at 400°C for 20 hours to obtain an NCM ternary cathode material with a surface lithium concentration gradient.

Embodiment 3

[0052] A preparation method of NCM ternary positive electrode material with surface layer lithium concentration gradient, comprising the following steps:

[0053] S1, the tartaric acid of 10mL is added in 50mL solvent, at 80 DEG C, stirring and mixing, stirring time is 10min, obtains mixed solution;

[0054] S2, put 20g of NCM ternary cathode material LiNi 0.8 Co 0.1 Mn 0.1 O 2 Add to the mixed solution obtained by S1, continue to maintain the stirring temperature of 80 ° C, and the soaking time is 30 min to obtain a suspension;

[0055] S3, S2 gained suspension under reduced pressure suction filtration, obtains solid filter material;

[0056] S4. The solid filter material is placed in a tube furnace, and the temperature is controlled in an oxygen atmosphere for heat treatment at 800° C. for 5 hours to obtain an NCM ternary cathode material with a surface layer lithium concentration gradient.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com