Enhanced rubber extrusion feeding device

A feeding device, enhanced technology, applied in the field of enhanced rubber extrusion feeding device, can solve the problems of easy agglomeration of materials, lower work efficiency, inconvenient manual operation, etc., to avoid accumulation and agglomeration, and improve production efficiency and quality, the effect of avoiding manual operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

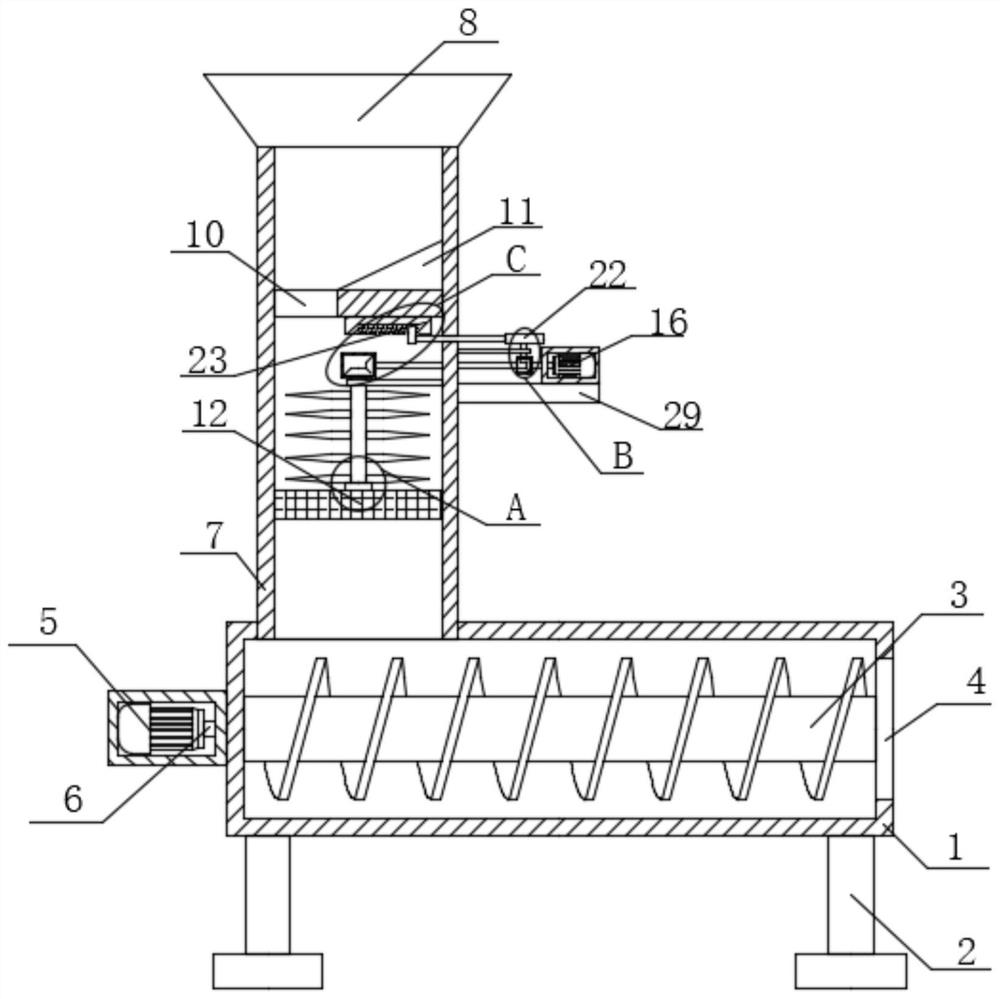

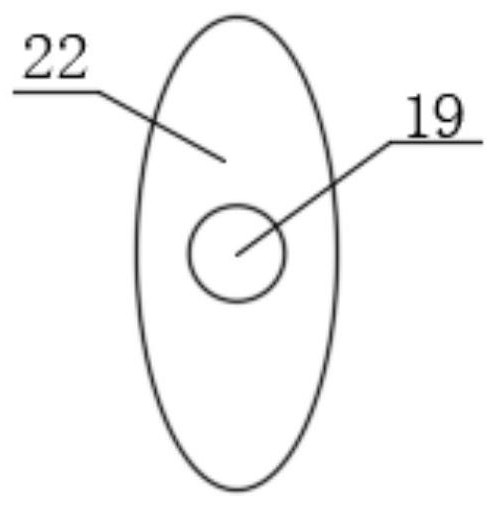

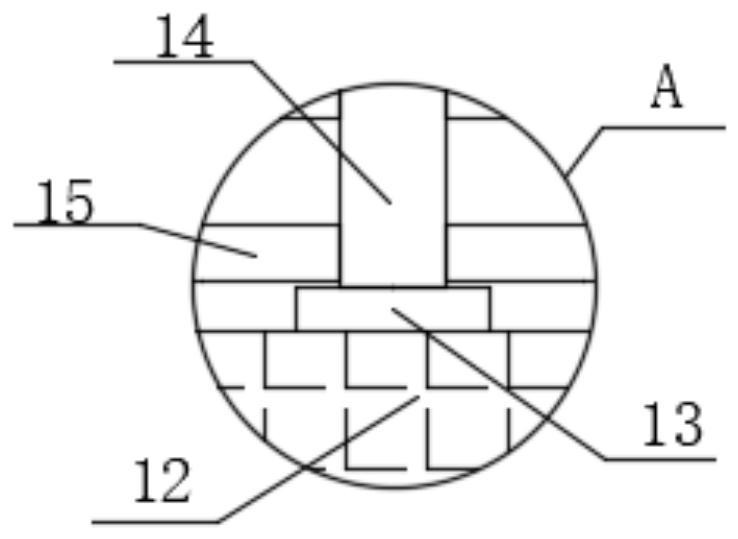

[0026] refer to Figure 1-5 , an enhanced rubber extrusion feeding device, comprising a box body 1, two brackets 2 are symmetrically and fixedly installed on the bottom of the box body 1, an extruding screw 3 is installed in rotation in the box body 1, and one side of the box body 1 is opened There is a discharge hole 4, and the other side of the box body 1 is fixedly installed with a first drive motor 5, and a drive shaft 6 is fixedly installed on the output shaft of the first drive motor 5, and the drive shaft 6 is far away from the output shaft of the first drive motor 5. One end is fixedly connected with the extruding screw 3, a treatment box 7 is fixedly installed on the top of the box body 1, a material guide cover 8 is fixedly installed on the top of the treatment box 7, a partition 9 is fixedly installed in the treatment box 7, and a Leakage 10 is arranged, the top of dividing plate 9 is fixedly installed with inclined plate 11, and filter screen 12 is fixedly installe...

Embodiment 2

[0035] refer to Figure 1-5 , a reinforced rubber extrusion feeding device, including a box 1, the bottom of the box 1 is symmetrically fixed with two brackets 2 by welding, the inside of the box 1 is rotated and installed with an extrusion screw 3, one part of the box 1 The side is provided with a discharge hole 4, and the other side of the box body 1 is fixed with a first drive motor 5 by screws, and a drive shaft 6 is fixedly installed on the output shaft of the first drive motor 5 by welding, and the drive shaft 6 is far away from the first drive shaft. One end of the output shaft of the driving motor 5 is fixedly connected with the extruding screw 3, the top of the box body 1 is fixedly installed with a treatment box 7 by welding, the top of the treatment box 7 is fixedly installed with a material guide cover 8 by welding, and the inside of the treatment box 7 is welded. A partition 9 is fixedly installed, and a leak hole 10 is provided on the partition 9. The top of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com