Hot melt glue gun

A technology of hot-melt glue guns and hoses, which is applied in coatings, devices for coating liquids on surfaces, etc., can solve problems such as not being able to meet actual needs, and achieve the effect of reducing the time for replacing glue sticks and making the operation simple and convenient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

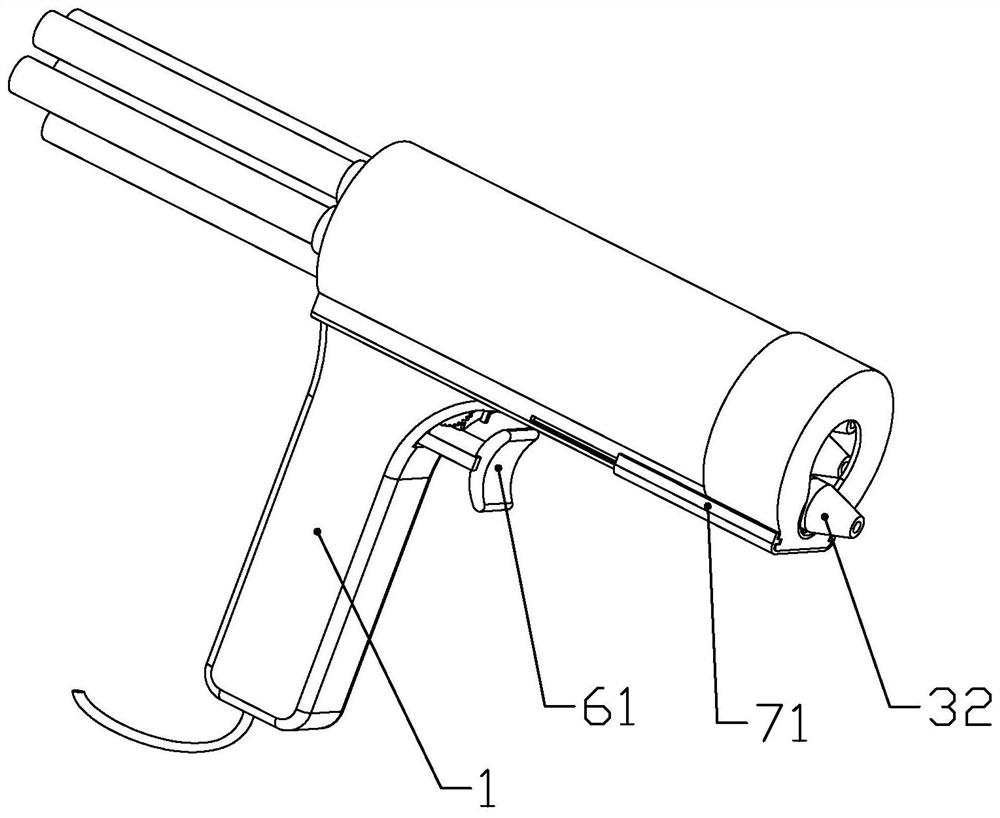

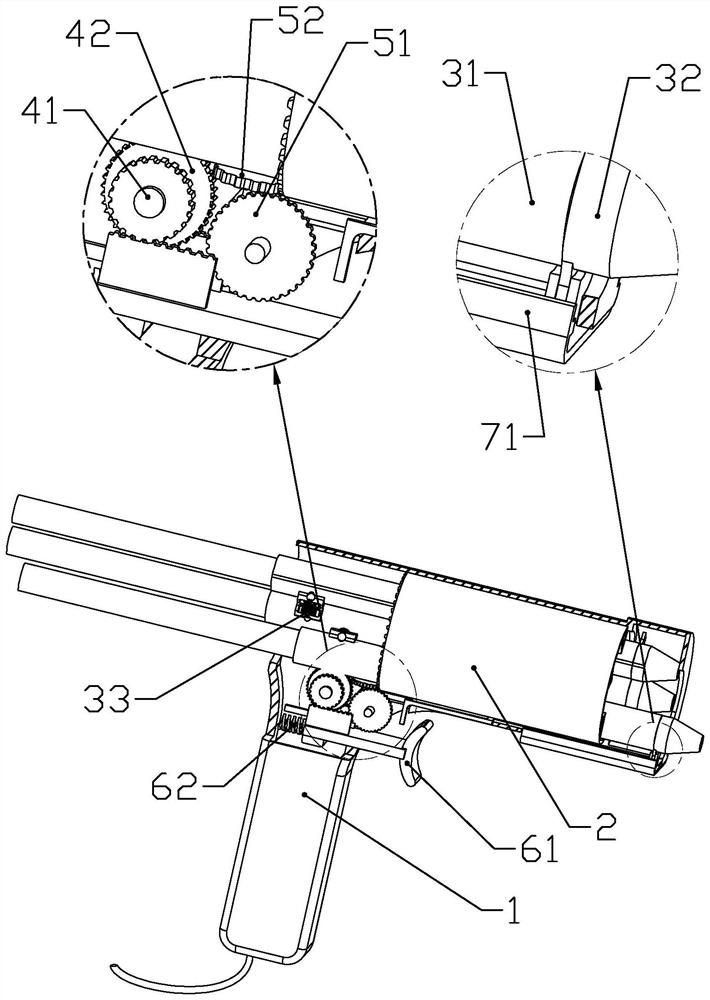

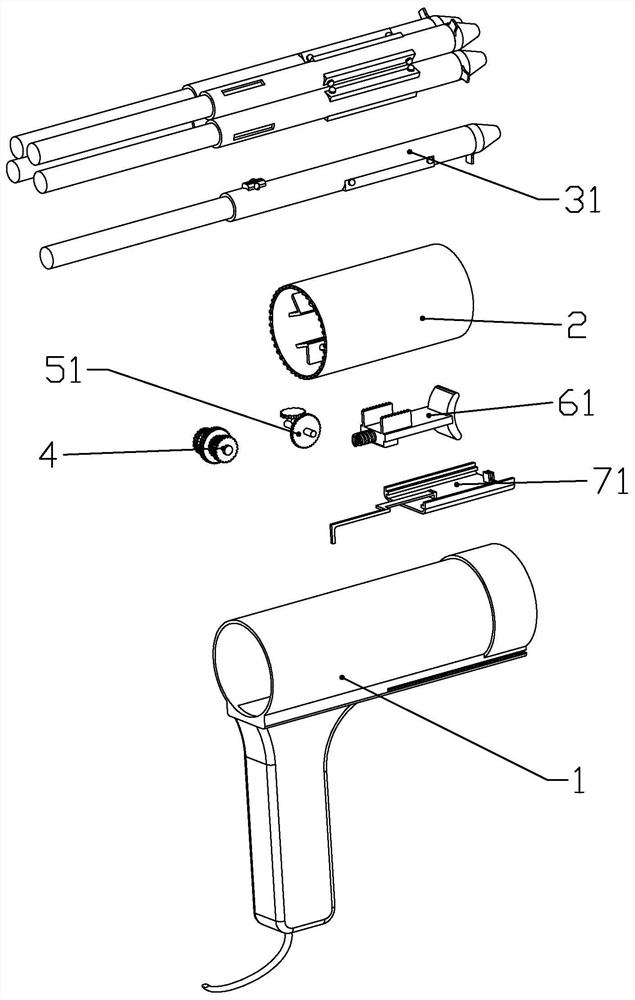

[0037] according to Figure 1 to Figure 13 As shown, a hot-melt glue gun described in this embodiment includes an outer casing 1; its feature is that: the outer casing 1 is rotatably connected with an inner rotating cylinder 2 whose rotating shaft is arranged along the front and rear directions; A plurality of rubber hoses 31 arranged along the front and back directions are evenly installed in the rotating cylinder 2 along the circumferential direction; the front ends of each of the rubber hoses 31 are respectively fixedly connected with a glue tap 32 capable of heating glue sticks; the inner rotating cylinder 2 can At the same time, glue sticks of various colors can be installed to meet different usage needs at the same time.

[0038] The inner wall of the inner rotating cylinder 2 is located on both sides of each of the rubber hoses 31 and is respectively formed with guide plates 22 arranged along the front and rear directions; the guide plates 22 are evenly formed with a pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com