Movable robot for carrying

A robotic and mobile technology, applied in the field of handling robots, can solve problems such as damage to material structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

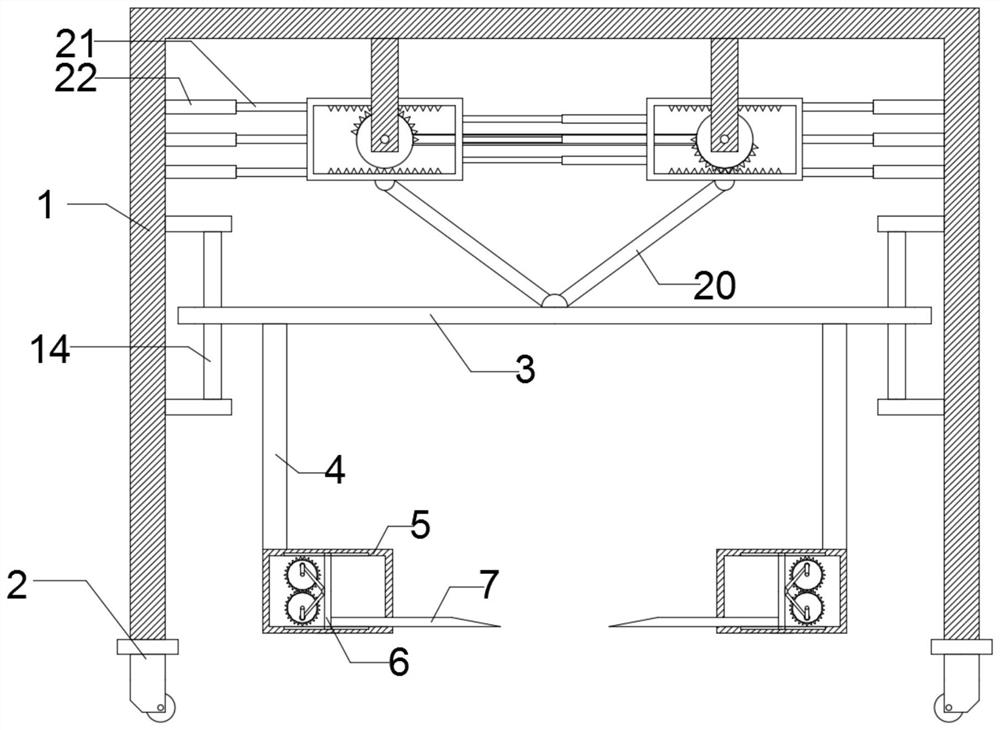

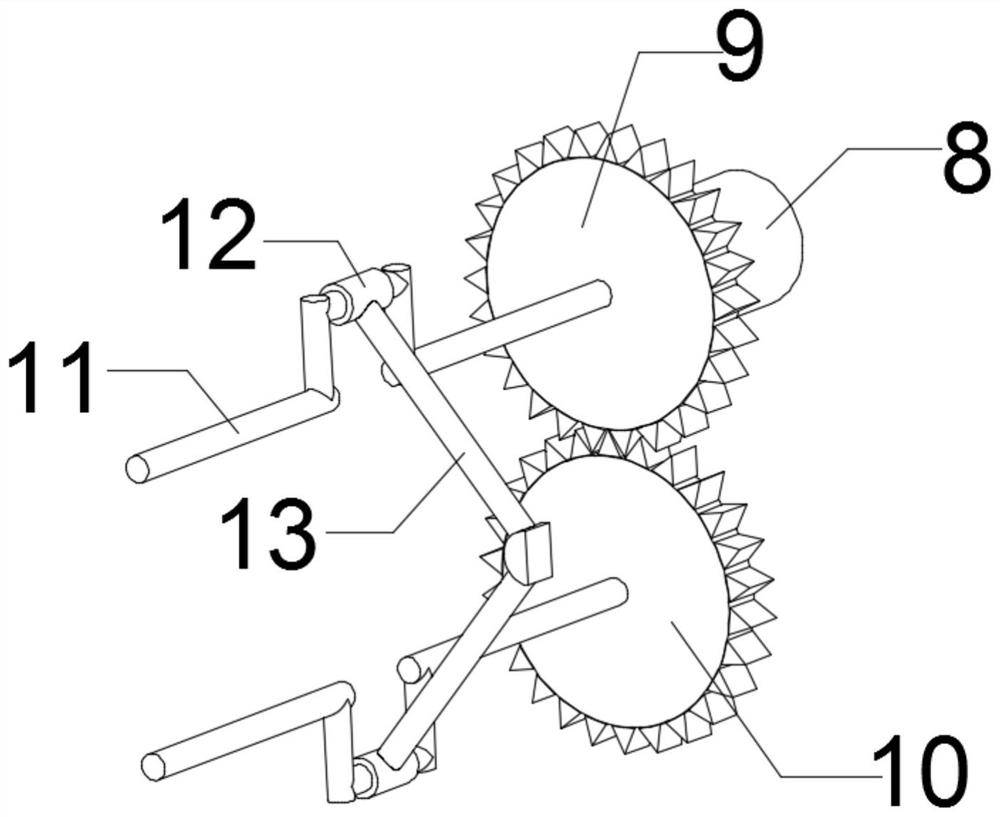

[0019] see Figure 1-3 , this embodiment provides a mobile robot for handling, including a bracket 1, a wheel device 2, a movable plate 3, a connecting plate 4 and a clamping warehouse 5; the bottom of the bracket 1 is symmetrically provided with multiple The wheel device 2, and the bracket 1 is provided with a movable plate 3; the bottom of the movable plate 3 is symmetrically fixed with a connecting plate 4, and the bottoms of the two connecting plates 4 are provided with a clamping warehouse 5; the two clamping warehouses Push plates 6 are all slid inside the 5; clamping plates 7 are fixed on the inner sides of the two pushing plates 6; There is a pushing mechanism that pushes the clamping plate 7 to move inward; in this way, when the material needs to be transported, the support 1 moves to the top of the material, and at this time, the two pushing mechanisms respectively push the two pushing plates 6 to move inward. Thereby promoting two clamping plates 7 to move inwardly...

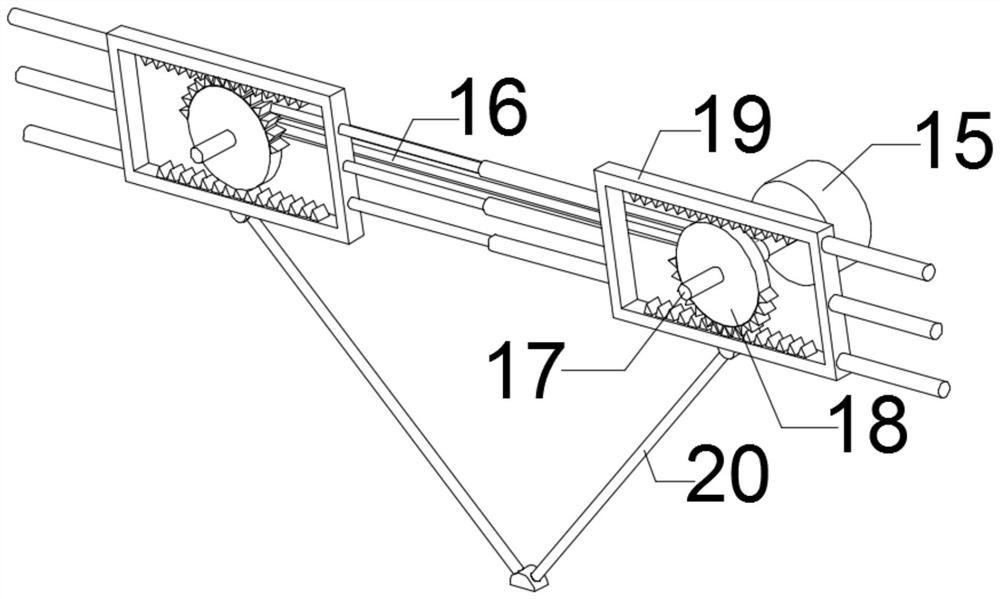

Embodiment 2

[0028] This embodiment is further improved on the basis of Embodiment 1. The improvement is: in order to make the two adjustment plates 19 more stable during movement, between the bracket 1 and the two adjustment plates 19, the two adjustment plates 19 A plurality of spacer rod structures are symmetrically arranged between them; the spacer bar mechanism includes an inner spacer bar 21 and an outer spacer bar 22; Inside.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com