A kind of Korean standard sd600 plate screw steel and its production method and preparation device

A preparation device and a technology for coiling snails, which is applied in the field of Korean standard SD600 coiled snail steel and its production method and preparation device, which can solve the problems of large labor force, hidden safety hazards, inconvenient operation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

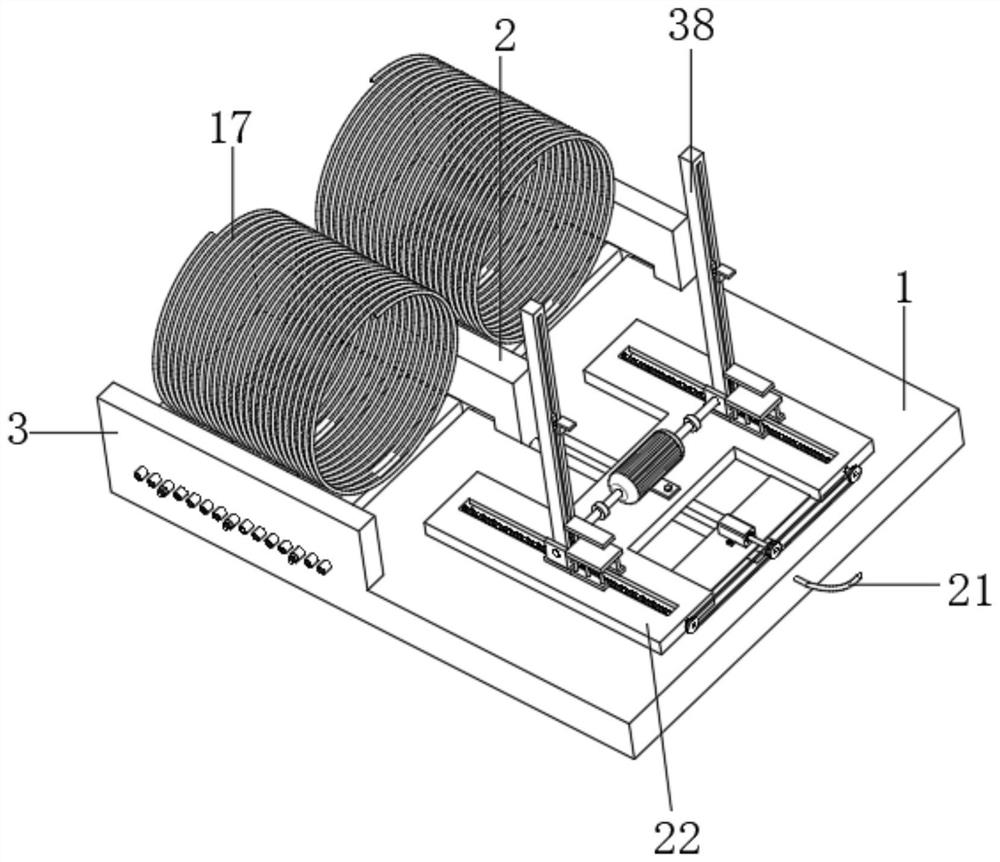

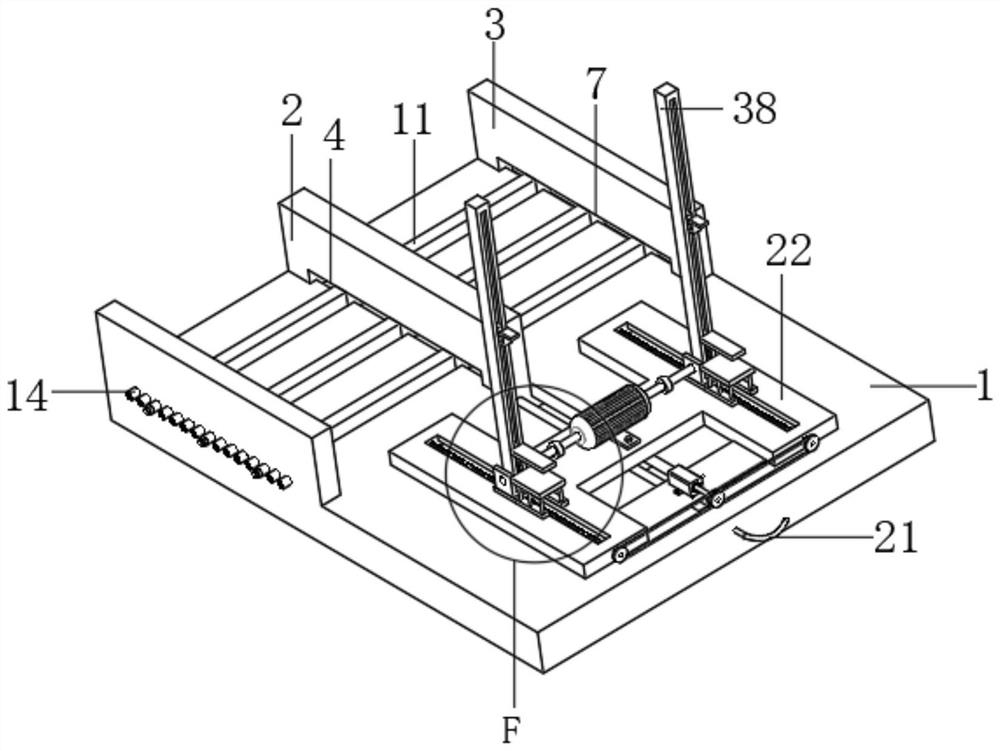

[0044] Such as figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 As shown, a Korean standard SD600 coil steel and its production method and preparation device include a flipping substrate 1, a stacking assembly arranged on the top center side of the flipping substrate 1, and the stacking assembly includes a central partition 2, a side plate 3, Center chute 4, center slide block 5, jack 6, side chute 7, side slide block 8, through hole 9, perforation 10, backing plate 11, matching hole 12 and connecting rod 13, lay flat on the backing plate 11 Pan screw steel 17;

[0045] The central partition 2 is fixed at the center of one half of the top center of the flipped base plate 1. There are two groups of side plates 3, which are symmetrically arranged on the top of the flipped base plate 1 with the central partition 2 as a symmetrical object. The central partition 2 and the side plates 3 The lengths and heights are the same respectively, one end of the central partition...

Embodiment 2

[0047] Embodiment 2 is a further improvement to Embodiment 1:

[0048] Such as Figure 6 , Figure 7 , Figure 8 and Figure 9 As shown, a moving chute 18 is provided on the center line of the other half of the top center of the flip substrate 1. One end of the moving chute 18 is flush with the side of the center partition 2 near the center of the top of the flip substrate 1. The inside of the moving chute 18 Sliding has mobile slide block 19, and the top of mobile slide block 19 is flush with the top of mobile chute 18 and mobile slide block 19 is an iron slide block, and the center of two ends of mobile chute 18 is provided with electromagnet bar 20, and electromagnet bar 20 activities run through mobile slide bar. block 19, one end of the electromagnet rod 20 is connected with a transmission line 21, and the transmission line 21 runs through the side of the flip substrate 1 and is arranged; the position of the mobile slider 19 can be adjusted by utilizing the sliding fit...

Embodiment 3

[0051] Embodiment 3 is a further improvement to embodiment 2:

[0052] Such as figure 2 , Figure 7 , Figure 8 , Figure 10 and Figure 11 As shown, the center of the top of the adjustment slider 25 is provided with an overturning assembly, and the overturning assembly includes a mounting plate 32, a concave frame 33, a bearing 34, a rotating rod 35, a double-head motor 36, a coupling 37, a rotating plate 38, and an auxiliary slide. Groove 39, auxiliary slider 40, screw hole 41, screw rod 42 and L plate 43;

[0053] The mounting plate 32 is fixed on the center of the top of the adjustment slider 25, and the concave frame 33 is fixed on the center of the top of the mounting plate 32. The horizontal plane at the top of the concave frame 33 is higher than the horizontal plane of the backing plate 11, and the bearing 34 rotates through the concave frame 33. The center of the side is set, the rotating rod 35 rotates in the bearing 34, the double-headed motor 36 is installed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com