Automatic foam adhesive film waste discharge production line

A cotton glue film, automatic discharge technology, applied in metal processing and other directions, can solve the problems of high labor intensity, low production efficiency, inexhaustible waste discharge, etc., to improve waste discharge efficiency, ensure product yield, and reduce labor intensity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

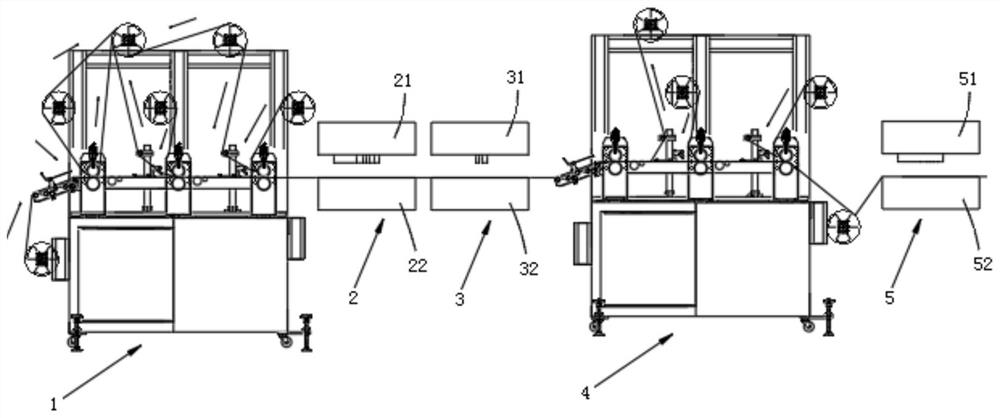

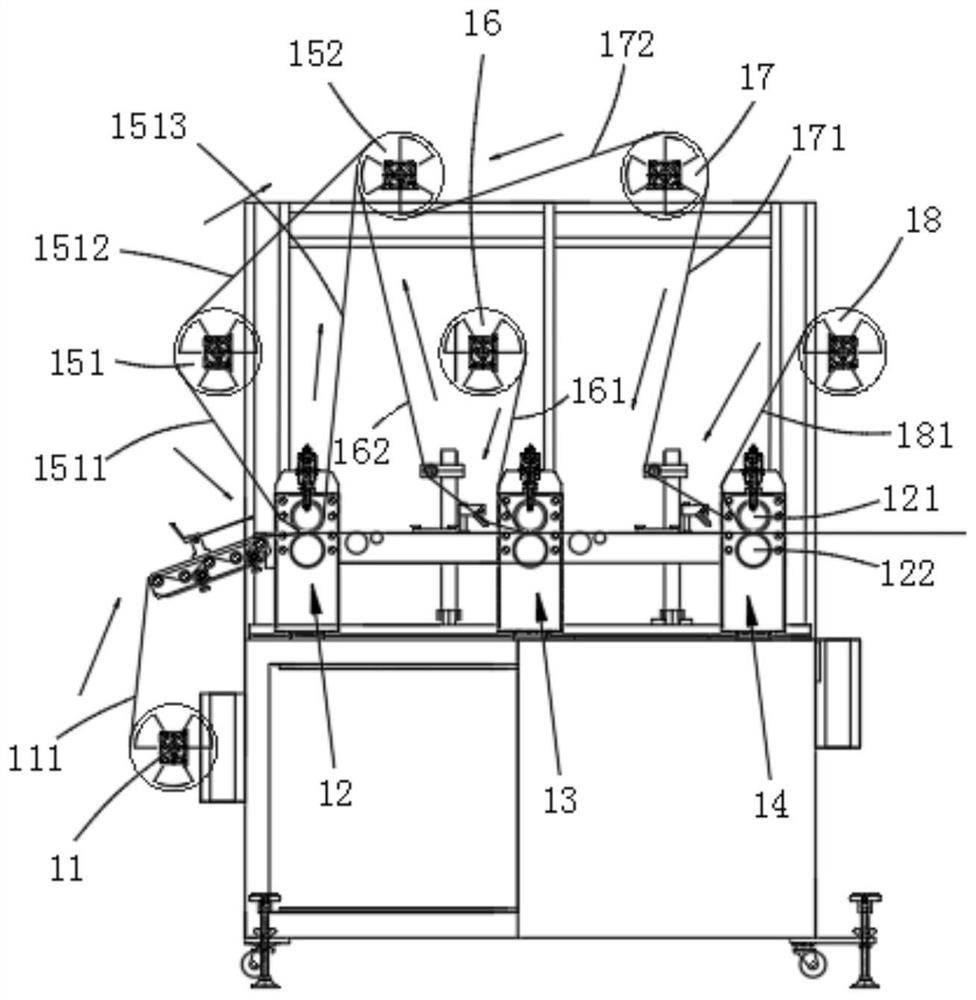

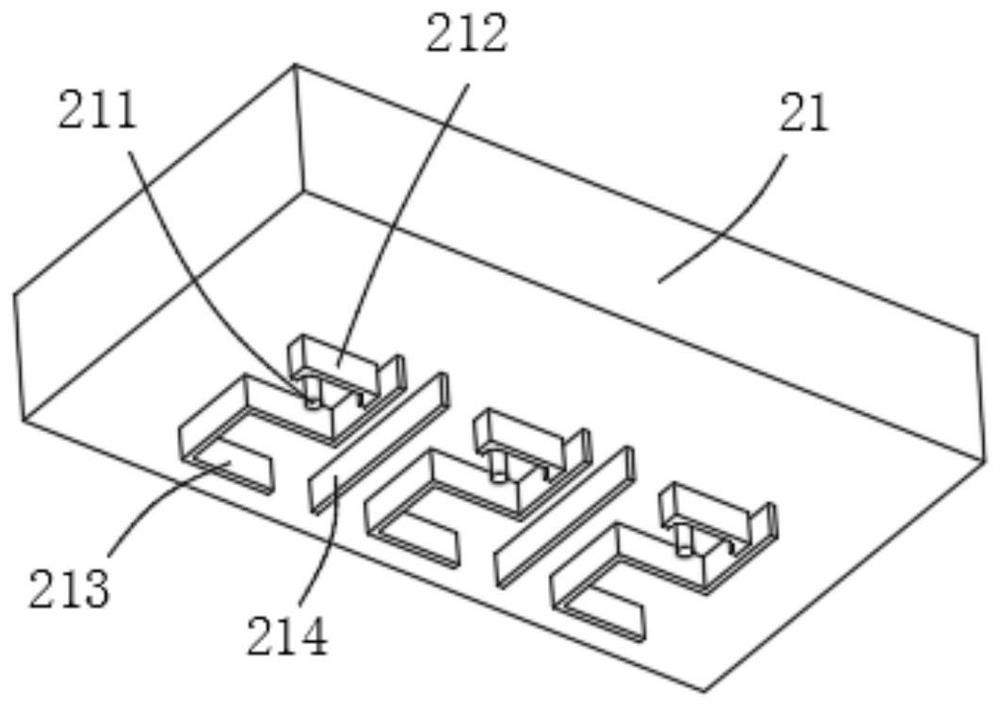

[0038] Embodiment: a kind of foam film automatic waste discharge production line, such as Figure 1-Figure 9 As shown, it includes a feeding device 1, a first die-cutting mechanism 2, a waste discharge mechanism 3, a bonding device 4 and a second die-cutting mechanism 5, and the feeding device 1 is located upstream of the first die-cutting mechanism 2 , the first die-cutting mechanism 2 is located upstream of the waste discharge mechanism 3, the waste discharge mechanism 3 is located upstream of the laminating device 4, and the laminating device 4 is located at the second die-cutting mechanism 5 upstream of

[0039] The feeding device 1 sequentially includes a protective film discharge roller 11, a first belt pressing mechanism 12, a second belt pressing mechanism 13 and a third belt pressing mechanism 14 according to the production process, and the protective film discharging roller 11 is covered with a protective film film 111, a first tape unwinding mechanism is provided a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com