Mask strip classification equipment and mask strip classification method

A technology of sorting equipment and sorting methods, which is applied in sorting and other directions, and can solve problems such as low netting yield, metal mask frame deformation, and hole position offset.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

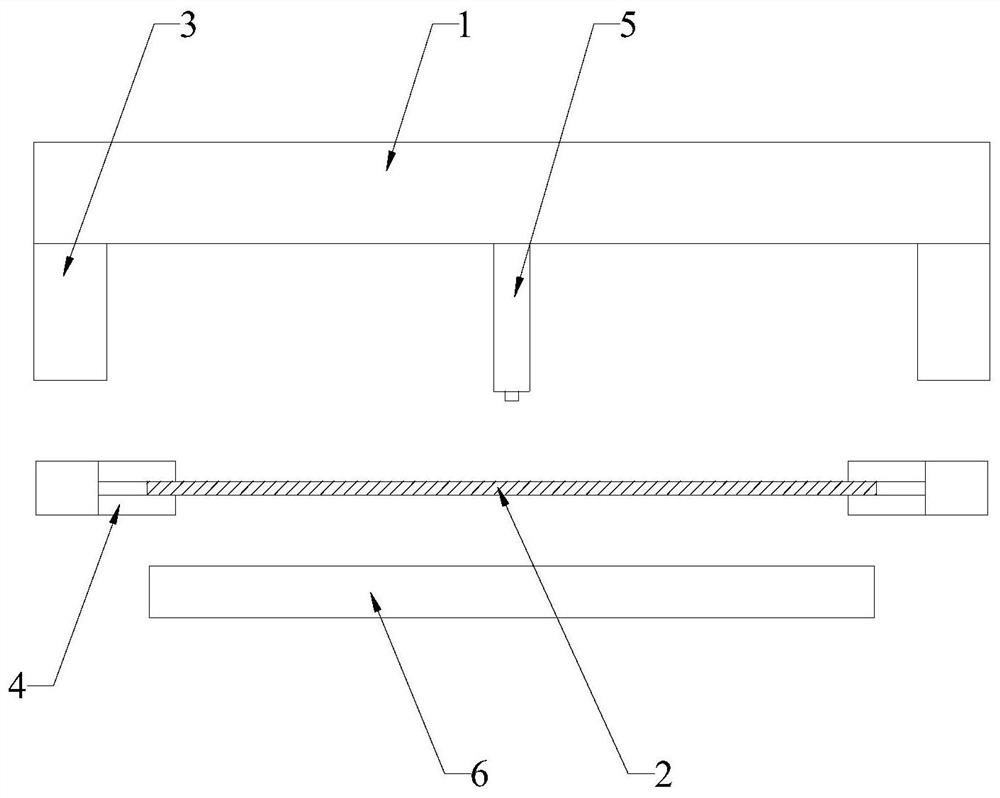

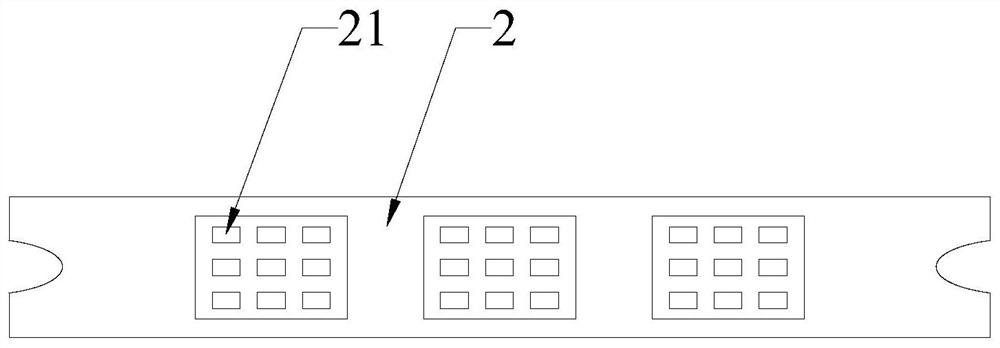

[0051] Please refer to figure 1 and figure 2 , Embodiment 1 of the present invention is:

[0052] Please refer to figure 1 , a sorting device for mask strips, comprising a frame and a moving mechanism 1, the frame is provided with a mask carrier, the moving mechanism 1 is located above the mask carrier, and the mask carrier is close to the moving mechanism A mask strip packaging box is placed on one side of the mask strip 1, and more than two metal mask strips 2 are placed in the mask strip packaging box, and a dust-free Paper, dust-free paper is used to isolate the friction damage caused between two adjacent metal mask strips 2, and the side surface of the moving mechanism 1 close to the mask stage is connected with more than two adsorption mechanisms 3, the The adsorption mechanism 3 is configured to adsorb the metal mask strip 2 and the dust-free paper in the mask strip packaging box;

[0053] Please refer to figure 1 , the opposite ends of one side of the frame are r...

Embodiment 2

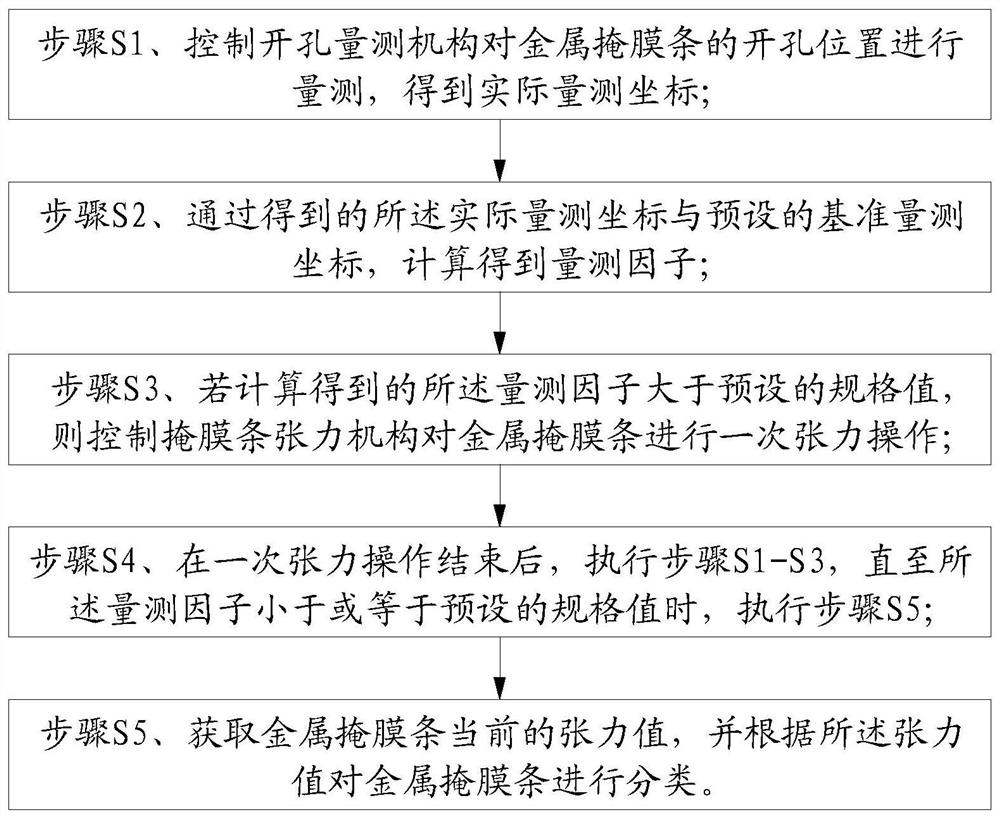

[0068] Please refer to image 3 and Figure 4 , the second embodiment of the present invention is:

[0069] Please refer to image 3 , a mask strip classification method, comprising the following steps:

[0070] Step S1, control the opening measuring mechanism 5 to measure the opening position 21 of the metal mask strip 2, and obtain the actual measurement coordinates; step S1 is specifically: control the opening measuring mechanism 5 to the metal mask strip 2 relative The opening positions 21 at the edges of both ends are measured to obtain actual measurement coordinates.

[0071] Step S2, calculating a measurement factor through the obtained actual measurement coordinates and the preset reference measurement coordinates;

[0072] Step S3, if the calculated measurement factor is greater than the preset specification value, then control the mask strip tension mechanism 4 to perform a tension operation on the metal mask strip 2; step S3 is specifically:

[0073] If the cal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com