Liquid nitrogen dumping device and dumping method thereof

A technology of pouring device and liquid nitrogen, which is applied in container filling method, container discharging method, container structure installation device, etc., can solve the problems of high operational risk factor, low work efficiency, high labor intensity, etc., and reduce safety risks. , the effect of reduced labor intensity and strong applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

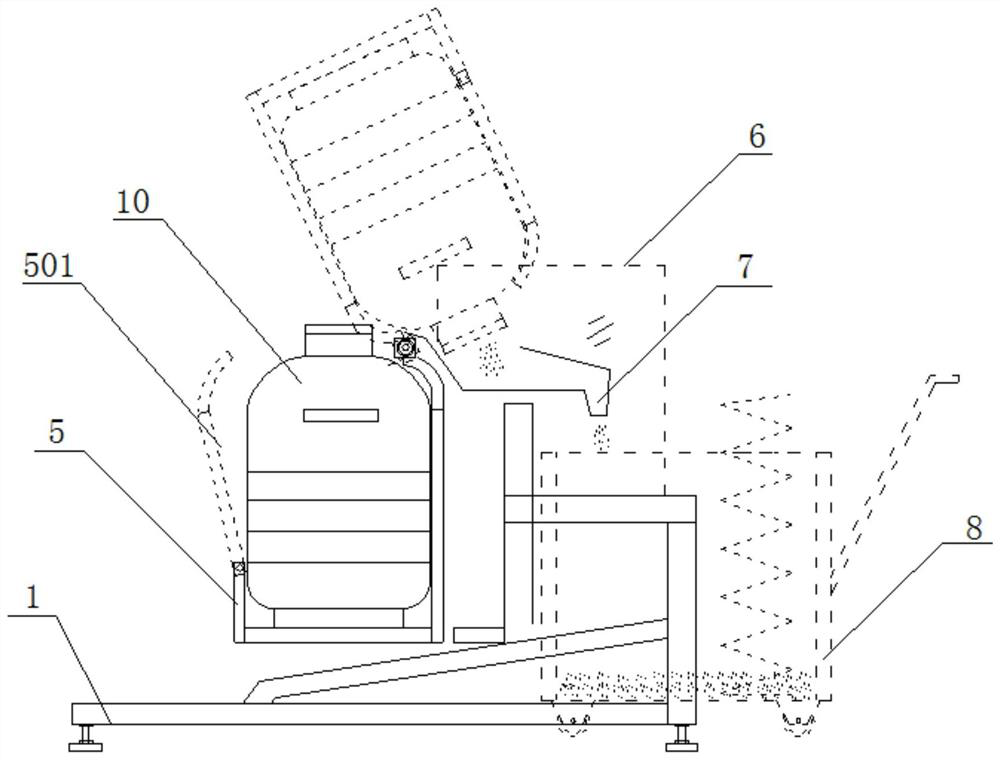

[0026] This embodiment discloses a liquid nitrogen pouring device, see figure 1 and figure 2 , the dumping device includes a frame 1, a driving mechanism, a rotating shaft 4, a liquid nitrogen tank hoop locking mechanism 5, a plexiglass protective cover 6 and a liquid nitrogen funnel 7.

[0027] The frame 1 is equipped with a controller 9 . The frame 1 has a driving mechanism installation platform and a rotating shaft support frame 101 .

[0028] The rotating shaft 4 is rotatably installed on the rotating shaft supporting frame 101 . The drive mechanism includes a geared motor 2 and a worm gear reducer 3 .

[0029] The geared motor 2 is fixed on the drive mechanism installation platform of the frame 1 . The controller 9 is connected to the geared motor 2, and controls the forward rotation and reverse rotation of the geared motor 2 through the controller 9.

[0030] The worm gear reducer 3 is fixed on the drive mechanism installation platform of the frame 1 , and the inpu...

Embodiment 2

[0039] This embodiment provides a relatively basic implementation, a liquid nitrogen pouring device, see figure 1 and figure 2 , including a frame 1, a driving mechanism, a rotating shaft 4, a liquid nitrogen tank hoop locking mechanism 5 and a liquid nitrogen funnel 7.

[0040] The frame 1 has a driving mechanism installation platform and a rotating shaft support frame 101 .

[0041] The rotating shaft 4 is rotatably installed on the rotating shaft supporting frame 101 .

[0042] The drive mechanism is fixed on the drive mechanism installation platform. The drive mechanism drives the rotating shaft 4 to rotate.

[0043] The hoop locking mechanism 5 of the liquid nitrogen tank is a square shell as a whole, the lower end of which is closed, and the upper end is bent inward to form a constriction. A side wall of the hoop locking mechanism 5 for the liquid nitrogen tank is provided with an openable and closable pressing plate 501, the lower end of the pressing plate 501 is h...

Embodiment 3

[0047] The main steps of this embodiment are the same as those of Embodiment 2, further, the drive mechanism includes a reduction motor 2 and a worm gear reducer 3 .

[0048] The geared motor 2 is fixed on the drive mechanism installation platform of the frame 1 . The controller 9 is connected to the geared motor 2, and controls the forward rotation and reverse rotation of the geared motor 2 through the controller 9.

[0049] The worm gear reducer 3 is fixed on the drive mechanism installation platform of the frame 1 , and the input end of the worm gear reducer 3 is connected to the output shaft of the reduction motor 2 . A drive gear 301 is fixedly connected to the output shaft of the worm gear reducer 3 .

[0050] A driven gear 401 is fixedly connected to the end of the rotating shaft 4 . The driven gear 401 meshes with the driving gear 301 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com