Automatic cloth elasticity testing device for workshop production

An automatic testing device and fabric technology, applied in the inspection of textile materials, textiles and papermaking, etc., can solve problems such as easy breaking of fabrics, arm soreness, and reduced testing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

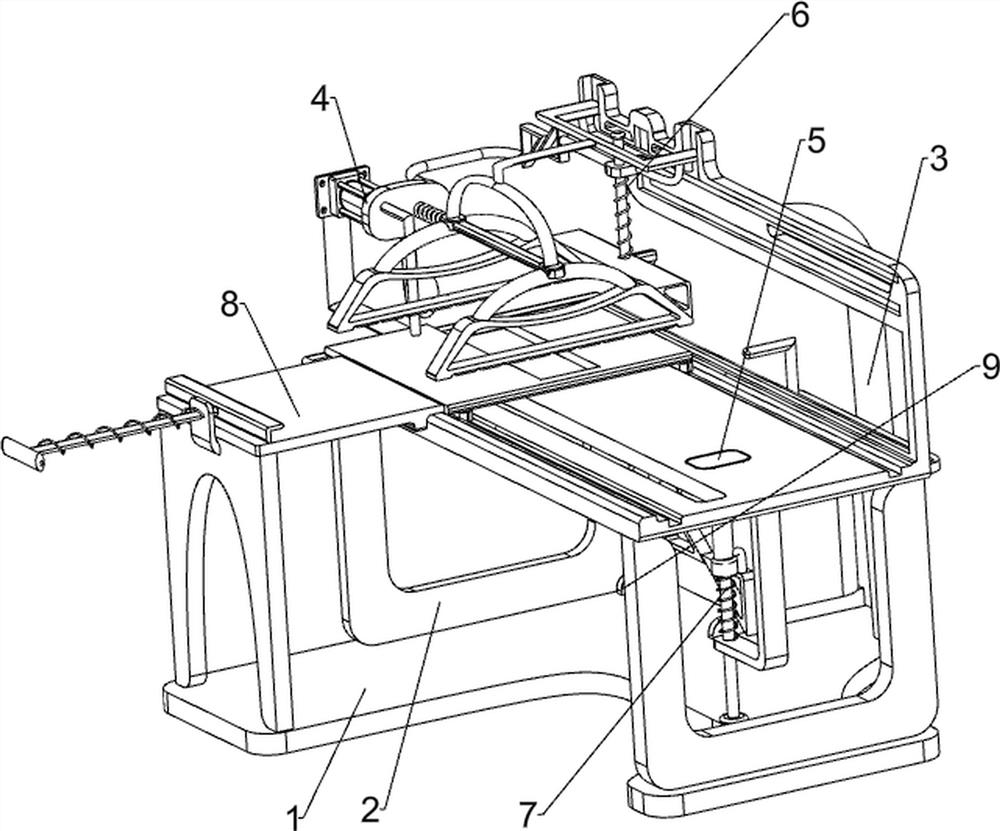

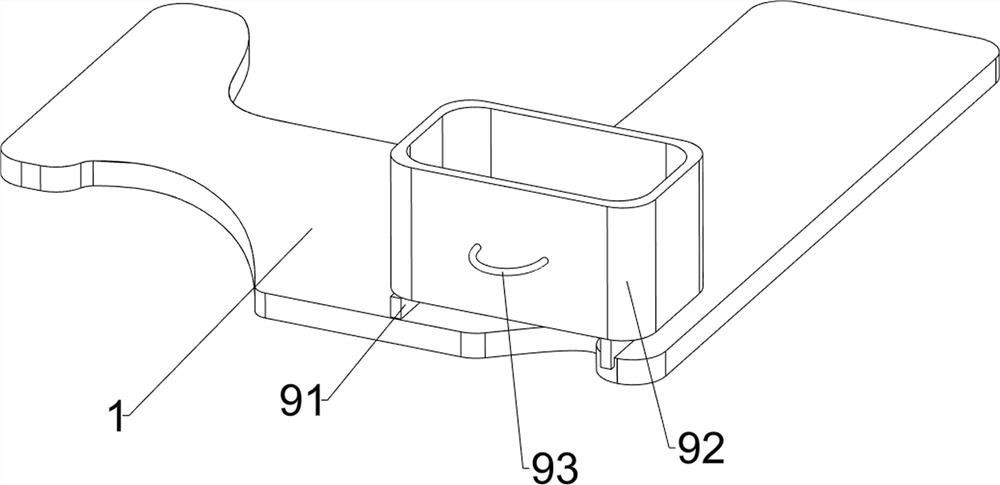

[0068] An automatic testing device for fabric elasticity in workshop production, such as figure 1 As shown, it includes a base 1, a first bracket 2, a second bracket 3, a pushing mechanism 4 and an extruding mechanism 5. The front and rear sides of the base 1 are provided with a first bracket 2, and the middle part of the right side of the base 1 is provided with a second bracket. Two brackets 3, a pushing mechanism 4 is provided between the tops of the two first brackets 2 and the second bracket 3, and an extruding mechanism 5 is arranged on the front side of the bottom of the pushing mechanism 4.

[0069]People put the elastic cloth to be detected on the push mechanism 4, start the push mechanism 4, the push mechanism 4 can push the elastic cloth forward, when the elastic cloth reaches the extrusion mechanism 5, push the extrusion mechanism 5 upward, the extrusion mechanism 5. Perform elasticity detection on the elastic cloth, then close the pushing mechanism 4 and reset the...

Embodiment 2

[0071] On the basis of Example 1, such as figure 2 and image 3 As shown, the pushing mechanism 4 includes a stand 41, a first supporting column 42, a cylinder 43, a first pushing block 44, a first sliding column 48, a discharge plate 46, a clamping block 45 and a first spring 47, two A platform 41 is connected between the tops of the first support 2 and the second support 3, the middle part of the rear side of the platform 41 is provided with a first support column 42, the top of the first support column 42 is equipped with a cylinder 43, and the output shaft of the cylinder 43 is provided with The first pushing block 44 is provided with a discharge plate 46 slidingly on the platform 41, and the rear part of the left side of the discharge plate 46 is provided with a first sliding column 48, and the top of the first pushing block 44 is slidably connected with the first sliding column 48 A clamping block 45 is slidingly provided on the top of the discharging plate 46, and the...

Embodiment 3

[0076] On the basis of Example 2, such as Figure 4-7 As shown, an automatic clamping mechanism 6 is also included, and the automatic clamping mechanism 6 includes a second support column 61, a first wedge block 62, a second wedge block 63, a third support column 64, a first slide block 65, a second support column 65, Three sliding columns 66 and the third spring 67, the first pushing block 44 rear wall is provided with the second supporting column 61, the right end of the second supporting column 61 is provided with the first wedge-shaped block 62, and the top of the clamping block 45 is provided with the first sliding block 65, the first slider 65 is slidingly connected with the upper right side of the stand 41, the bottom of the first slider 65 is provided with a third support column 64, the rear end of the third support column 64 is provided with a second wedge block 63, and the second wedge The block 63 is in contact with the first wedge block 62, and the middle part of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com