Logistics storage rapid unloading device and method

An unloading device and fast technology, applied in the field of storage and transportation, can solve the problems of inability to clamp and protect, and achieve the effects of convenient operation, preventing shaking and falling off, and reducing manual handling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

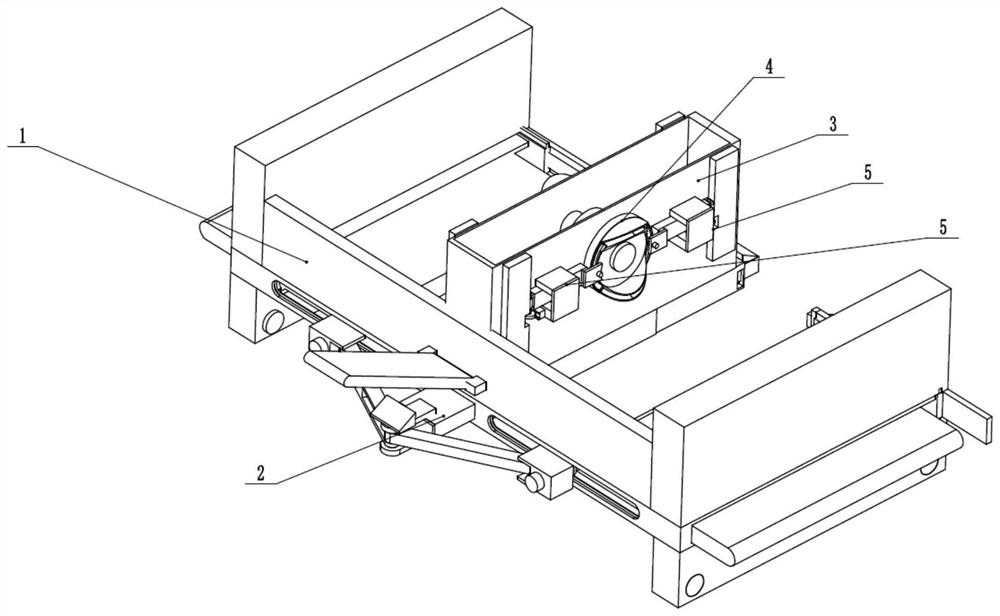

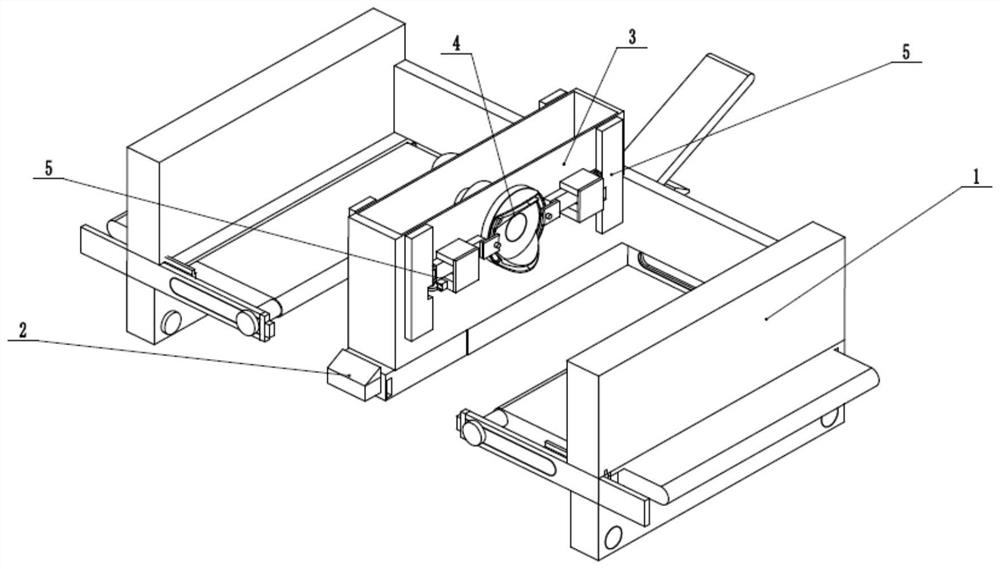

[0032] Such as Figure 1 to Figure 10 As shown, a fast unloading device for logistics storage includes a transport pull frame 1, a pedal unloading transfer device 2, a central fixed frame 3, a clamping driver 4 and four transport clamps 5, and the pedal unloading transfer device The device 2 is slidably connected to the lower end of the transport frame 1, the central fixed frame 3 is fixedly connected to the middle end of the transport frame 1, the pedal unloading transmitter 2 is engaged with the clamping driver 4 for transmission, and the clamping driver 4 is connected in rotation In the central fixed frame 3, four transport clamps 5 are evenly slidably connected in the clamping driver 4, and the four transport clamps 5 are all engaged with the central fixed frame in 3 directions for transmission. Place the goods to be transported and stacked on the transport pull frame 1 and the pedal unloading conveyor 2, and transport them to the designated position by pulling the transpo...

specific Embodiment approach 2

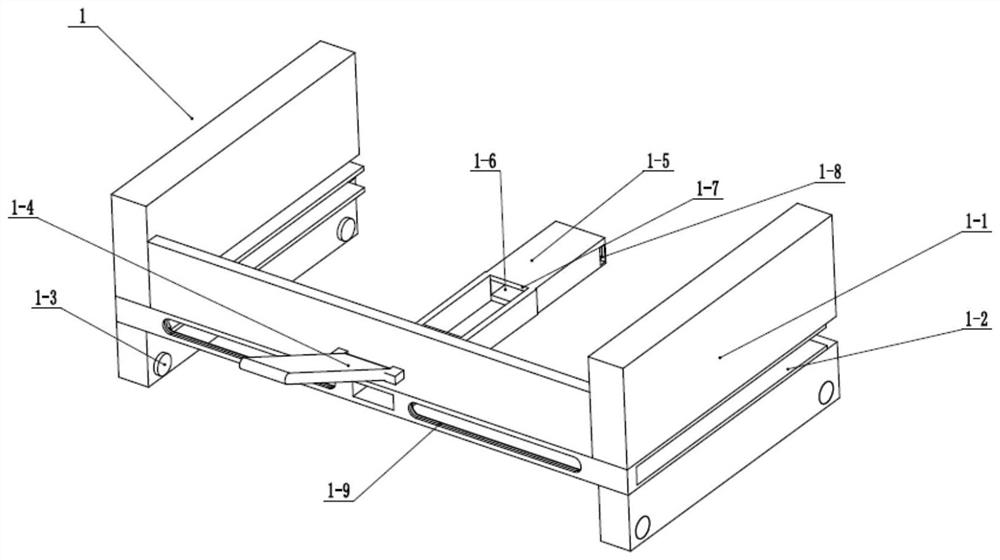

[0034] Such as Figure 1 to Figure 10As shown, this embodiment will further explain Embodiment 1. The transport pull frame 1 includes a pull frame 1-1, two side unloading plate chutes 1-2, four bottom wheels 1-3, and hinged pull rods. 1-4, center fixing seat 1-5, center rack chute 1-6, through connecting groove 1-7, two support slots 1-8 and two unloading shaft chute 1-9, two side unloading The plate chute 1-2 runs through the lower side of the two ends of the trolley frame 1-1, the four bottom wheels 1-3 are evenly rotated and connected to the lower end of the trolley frame 1-1, and the hinged pull rods 1-4 are hinged on the trolley. The rear end of the frame 1-1, the central fixed seat 1-5 is fixedly connected to the center of the inner end of the trolley frame 1-1, and the center rack chute 1-6 runs through the front and rear of the trolley frame 1-1 and the central fixed seat 1 On -5, the through communication groove 1-7 is set at the middle end of the central fixing base...

specific Embodiment approach 3

[0036] Such as Figure 1 to Figure 10 As shown, this embodiment will further explain the second embodiment. The pedal unloading transmitter 2 includes a pedal plate 2-1, a V-shaped hinged rod 2-2, a central drive rack 2-3, two hinged Seat 2-4, two unloading shafts 2-5, two unloading plates 2-6, two front connecting slide plates 2-7, two front connecting insert plates 2-8 and back pedal 2-9, pedal plate 2-1 is fixedly connected to the upper end of the V-shaped articulated rod 2-2, and the V-shaped articulated rod 2-2 is fixedly connected to the rear end of the central driving rack 2-3 through a hinged fixing seat, and the central driving rack 2-3 is slidably connected In the central rack chute 1-6, the two sides of the front end of the V-shaped hinged rod 2-2 are respectively hinged with two hinged seats 2-4, and the two hinged seats 2-4 are fixedly connected to the two unloading shafts 2-5 respectively. Two unloading shafts 2-5 are respectively slidably connected in two unloa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com