Pretreatment device for vegetable drying

A vegetable and rotating device technology, which is applied to the preservation of fruits and vegetables, the preservation of fruits/vegetables by heating, and the preservation of fruits/vegetables by dehydration, etc., can solve the problem that the petioles and leaves cannot be individually killed, and achieve the effect of improving the killing effect, ingenious design, The effect of preventing jamming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

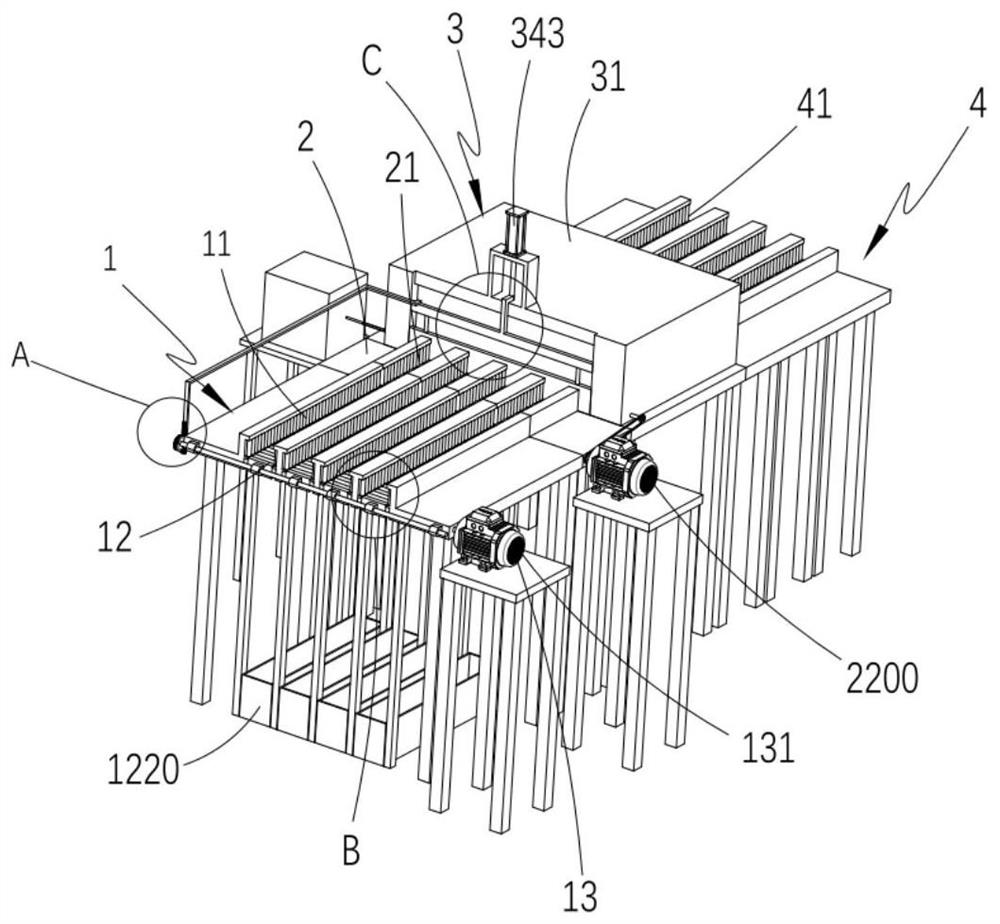

[0049] like Figure 1 to Figure 4 Shown, a kind of vegetable drying pretreatment device comprises:

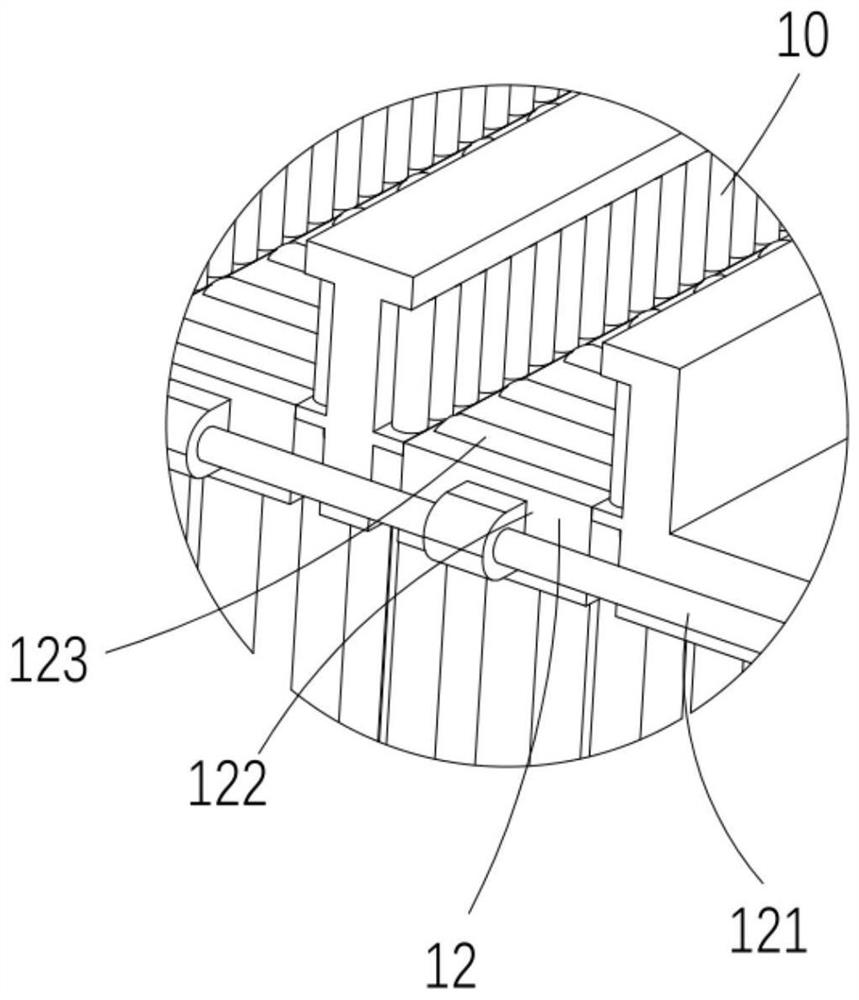

[0050] The feeding device 1, the feeding device 1 includes several sets of conveying passages a11 arranged in parallel, a rotating device 12 that is rotatably installed in the conveying passage a11 and can convey vegetable leaves forward and reverse, and is rotationally docked with the rotating device 12 And drive several groups of said rotating devices 13 to forwardly transport the driving assembly 13 of the vegetable leaves;

[0051] Sorting device 2, said sorting device 2 includes a conveying passage b21 correspondingly connected with said conveying passage a11 and several groups of rotating rollers b22 installed in said conveying passage b21 and used for conveying vegetable leaves in synchronous rotation;

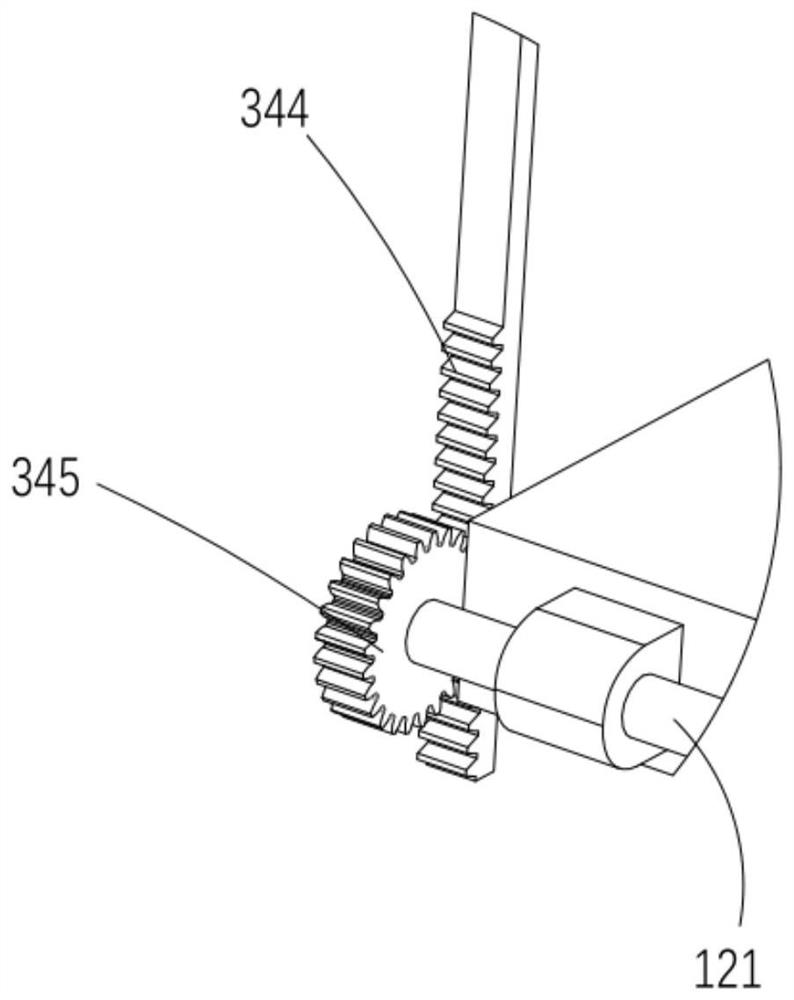

[0052] The de-enzyming device 3, the de-enzyming device 3 includes a box body 31 arranged on the rear side of the sorting device 2 along the conveying direction of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com