Lifting electromagnet only sucking single steel plate

A lifting electromagnet and electromagnet technology, which is applied in the field of lifting electromagnet, can solve the problems of unsafe lifting operation, inability to lift by suction, and inability to accurately lift a steel plate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

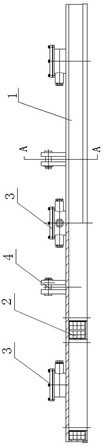

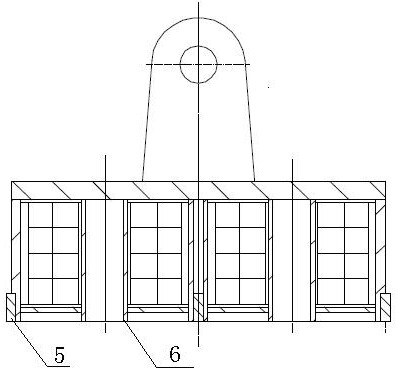

[0013] Lifting electromagnet structure of the present invention such as Figure 1-4 As shown, at least one hollow inner magnetic pole 6 is longitudinally provided inside the electromagnet 1, and the hollow inner magnetic pole 6 is a cylindrical structure bent from a steel plate whose thickness is not greater than the minimum thickness of the sucked steel plate. The two sides of the electromagnet 1 are provided with outer magnetic poles 5 , The electromagnet 1 is provided with a coil 2 inside, and the coil 2 is connected to the junction box 3 on the upper part of the electromagnet 1 . There are six coils 2 inside the electromagnet 1, the first coil 2-1, the second coil 2-2, the fifth coil 2-5 and the sixth coil 2-6 located on both sides are connected in series, and the third coil located in the middle The coil 2-3 and the fourth coil 2-4 are connected in series, and the lifting lug 4 is installed on the upper part of the electromagnet 1 .

[0014] The inner pole core of the el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com