Wheel hub motor

A technology for in-wheel motors and motor shafts, which is applied in the directions of electromechanical devices, electrical components, and electric components, can solve the problems of reducing motor life, waste of resources, and difficulty in heat, and achieves the improvement of service life, reduction of waste of resources, and reduction of maintenance costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

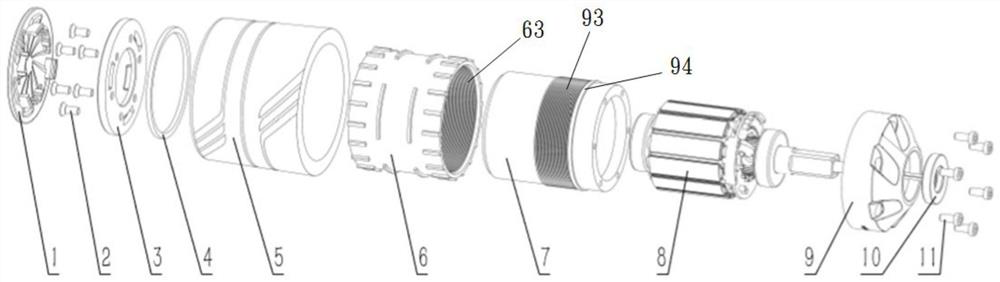

Embodiment 1

[0036] This embodiment provides a hub motor. see Figure 1 to Figure 5 , the hub motor includes a motor and a tire. The motor includes a rotor assembly, the tire includes an inner core 6 and a tire skin 5 covering the outside of the inner core 6, the inner core 6 has a fastening portion; Matching engaging part; the inner core 6 is sheathed on the rotor assembly, and the engaging part fits with the engaging part so that the inner core 6 can be driven when the rotor assembly rotates synchronous rotation; the hub motor also includes a gland 3 fixed on the left end surface of the rotor assembly, and the right side of the gland 3 presses against the left end surface of the inner core 6 .

[0037] see figure 2 and image 3 , the inner core 6 of the tire is a hollow cylindrical structure, and the tire skin 5 and the inner core 6 are directly casted.

[0038] The motor also includes a stator assembly 8, a motor shaft 12, a left side bearing 14, a right side bearing 15 and a moto...

Embodiment 2

[0049] This embodiment provides a hub motor. The difference from the first embodiment is only that the gland 3 and the inner core 6 are integrated. Compared with Embodiment 1, in the process of replacing the tire, after the first screw 2 fixing the gland 3 is loosened, there is no need to store the gland 3 additionally, which reduces the risk of parts loss .

Embodiment 3

[0051] This embodiment provides a hub motor. It differs from Embodiment 1 in that, see Figure 6 and Figure 7 , there is no protruding ring on the outer surface of the inner core 6, and the engaging portion is a plurality of protrusions 91 arranged on the left end surface of the end cap 9; the engaging portion is arranged on the inner There are a plurality of depressions 61 on the right end surface of the core 6; the inner core 6 is sleeved on the cylinder shell 7, and the plurality of protrusions 91 are embedded in the plurality of depressions 61 one by one. In this embodiment, the left end surface of the end cap 9 is provided with 6 protrusions 91 distributed at equal phase angle intervals, and the right end surface of the inner core 6 is provided with 6 depressions distributed at equal phase angle intervals. 61, so that the inner core 6 can be fixed to the rotor assembly by aligning the plurality of depressions 61 with the plurality of protrusions 91 respectively, so as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com