Method for calculating hot-spot temperature of axial double-hole copper bar rotor coil of generator

A technology of rotor coil and hot spot temperature, which is applied in the field of rotor coil hot spot temperature calculation of generator axial double-hole copper row, can solve the problems of incomplete application, inability to accurately calculate the hot spot temperature rise of rotor coil, and complicated use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0138] In order to make the present invention more comprehensible, preferred embodiments are described in detail below with accompanying drawings.

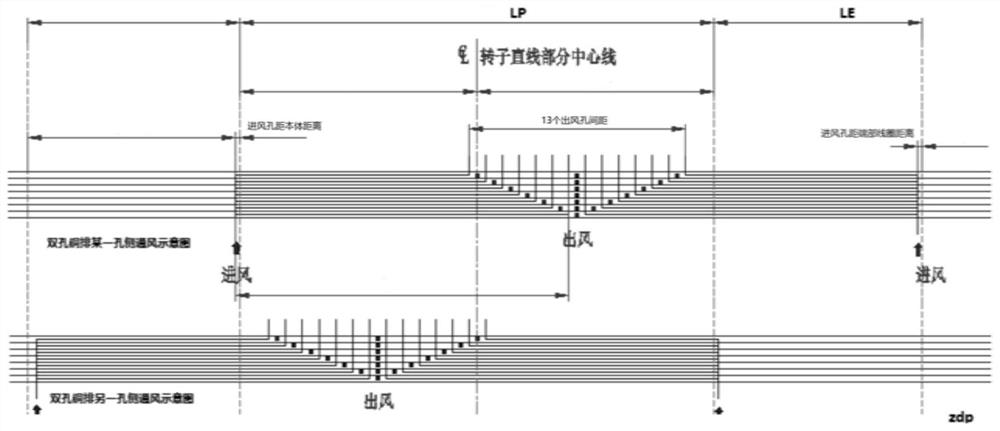

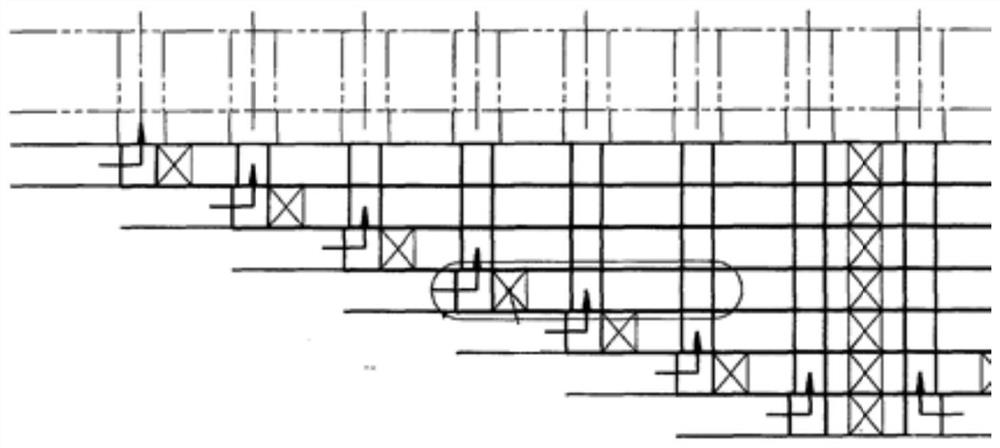

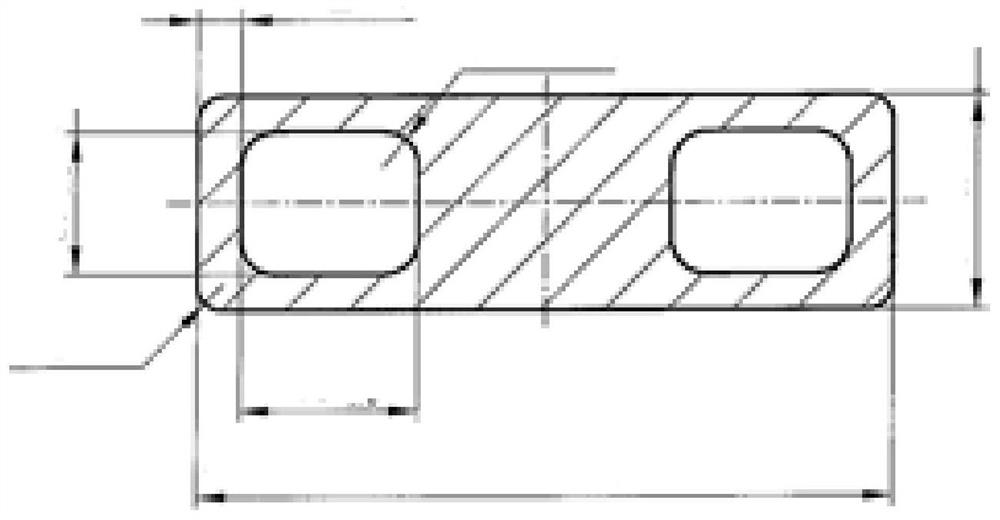

[0139] The realization of the method of the present invention is illustrated according to a large-scale steam turbine generator parameter example. A method for calculating the hot spot temperature of the axial double-hole copper row rotor coil of the generator according to the present invention is modularized according to the function, and the entire calculation process is divided into input data. Module, wind path iterative calculation module, loss and temperature rise calculation module, with clear functional modules and easy-to-use and upgrade calculation programs. From figure 1It can be seen that the copper bars on both sides are designed to be rotationally symmetrical, so one side can be taken for calculation, and then the two sides can be combined for calculation. The hot spot temperature is located on the No. 7 coil. The c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com