Dividing wall type heat exchanger temperature self-adaptive tracking control system with fault tolerance function

A heat exchanger temperature, adaptive tracking technology, applied in the direction of temperature control, temperature control by electric means, control/regulation system, etc., can solve the loss of people's life and property safety, affect the normal operation of the device, and the failure of valve actuators and other problems, to reduce the accident rate, improve production efficiency and economic benefits, and achieve the effect of stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

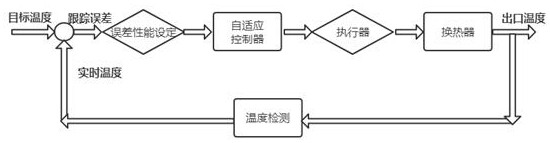

[0021] Such as figure 1 As shown, the heat exchanger temperature adaptive tracking control system is composed of an error performance setting unit, an adaptive controller, an actuator, a heat exchanger and a temperature detection unit.

[0022] Specific steps:

[0023] (1) Design the temperature error performance index according to the actual process conditions, so that the accuracy range can reach within 1%;

[0024] (2) Design a general actuator fault identification model, including two situations of stuck and failure;

[0025] (3) Adaptive controller is designed by backstepping method;

[0026] (4) After completing the above steps, the operation process of the system is as follows: firstly, set the pre-reached target temperature value of the outlet of the heat exchanger, and then feedback the actual outlet temperature of the current heat exchanger detected in real time to form a closed-loop loop to obtain the target temperature and The tracking error value of the actual ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com