Method for drying pig feed in pig feed raw material storage tank

A technology for raw material storage and pig feed, applied in the field of pig feed processing, can solve the problems of mildew easily and high internal humidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

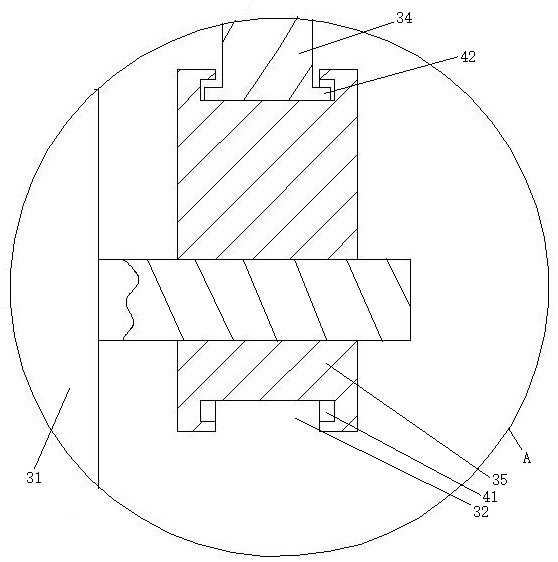

[0029] Example 1, see figure 1 with figure 2 A method for drying a pig feed in a pig feed raw material storage tank, a pig feed feed storage tank comprises a storage tank 1, a blower 2, and a blowing tube 3 extending from the top wall of the storage tank into the storage tank 3. The lower end of the blower is supported on the bottom wall of the storage tank. An discharge port 4 is provided on the bottom wall of the storage tank. A storage valve is provided on the reservoir. The storage tank is wearing a inner sleeve 5 in a blow pipe. The inner sleeve is isolated in the storage tank from the annular venting cavity 6 in which the inner sleeve extension is inserted. The annular vent cavity is provided with a vent cavity portion outlet valve 7. The inner set is provided with a number of inner-sleeves inner interior space and a ring out of the ring. The blowing tube is located on the side wall of the portion of the storage tank with a plurality of blowing pipes. The upper end of the ...

Embodiment 2

[0031] The second embodiment, the difference between the same example:

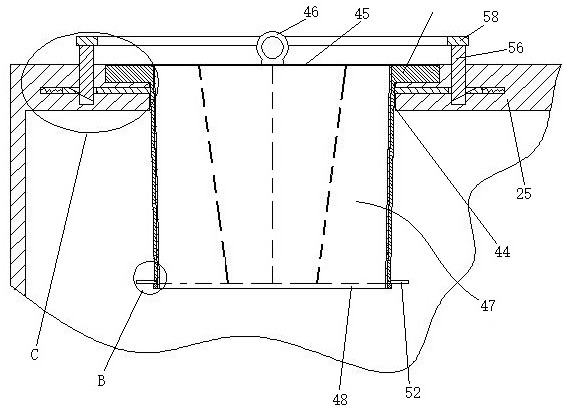

[0032] See Figure 3 to Figure 5 The pig feed raw material storage tank also includes a small feed tube at the lower end of the upper end. All wound trays and winding motors are located inside the storage tank. A feed hole 44 is provided on the top wall of the storage tank. The feed hole is provided with a feed hole cover 45. A pull ring 46 is provided on the upper end surface of the feed hole cover. The feed tube 47 can be inserted into the feed hole. The feed tube includes a rigid bottom ring 48, a conical flexible tube 49, and a plurality of rigid vertical pendulum 60, a rigid vertical pendulum rod, a rigid vertical pendulum, a ferromagnetic body. The lower end of the rigid vertical pendulum rod is hinged together with a rigid bottom ring through the horizontal axis head 50. The tapered flexible tube is unfolded, the upper end opening is small. The diameter of the feed hole is larger than the outer diameter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com