Dynamic shaft hole assembling device and method based on multi-camera visual servo

A multi-camera vision and dynamic axis technology, applied in manipulators, program-controlled manipulators, metal processing, etc., can solve problems such as difficult continuous assembly hole positioning and tracking, dynamic position uncertainty of mobile assembly holes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

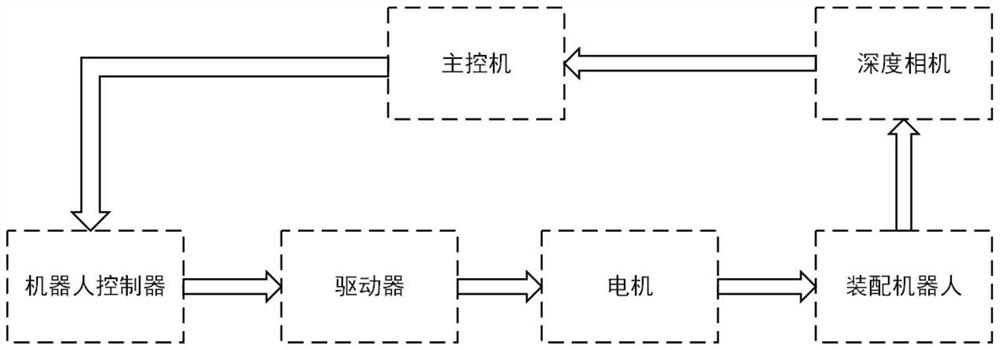

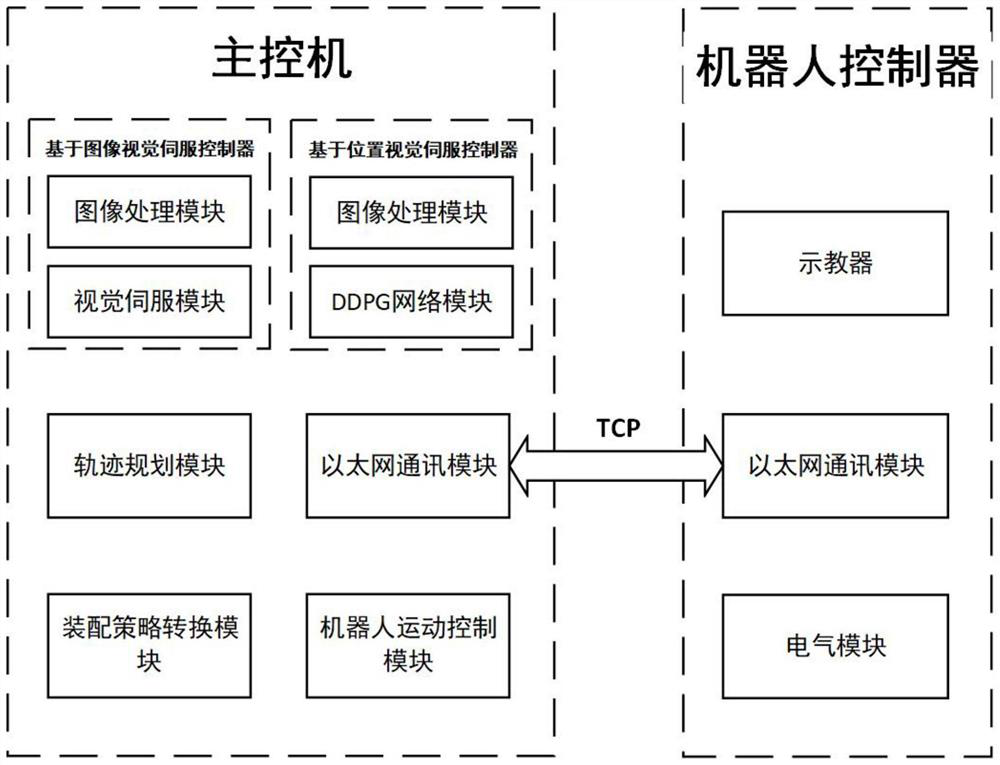

[0068] In order to make the purpose of the present invention, technical solutions and advantages clearer, now will figure 1 It is a specific embodiment that the drive shaft 6 is installed in the assembly hole 4 on the assembly platform 5 as shown in the figure, and the specific implementation mode of the present invention will be further described in detail.

[0069] Such as figure 1 , 2 As shown, the dynamic shaft hole assembly device includes a mechanical part and a control part;

[0070] The mechanical part includes operating platform 9, assembly robot 1, tool flange 2, driving shaft bracket 8, driving shaft 6, camera pan / tilt 7, tripod 12, linear guide rail 10, assembly hole 4 and assembly platform 5; the control part includes the main control machine 13, robot controller 16, depth camera A3 and depth camera B11;

[0071] The operating platform 9 and the linear guide rail 10 fixed on the operating platform and the assembly robot 1, the linear guide rail 10 is provided w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com