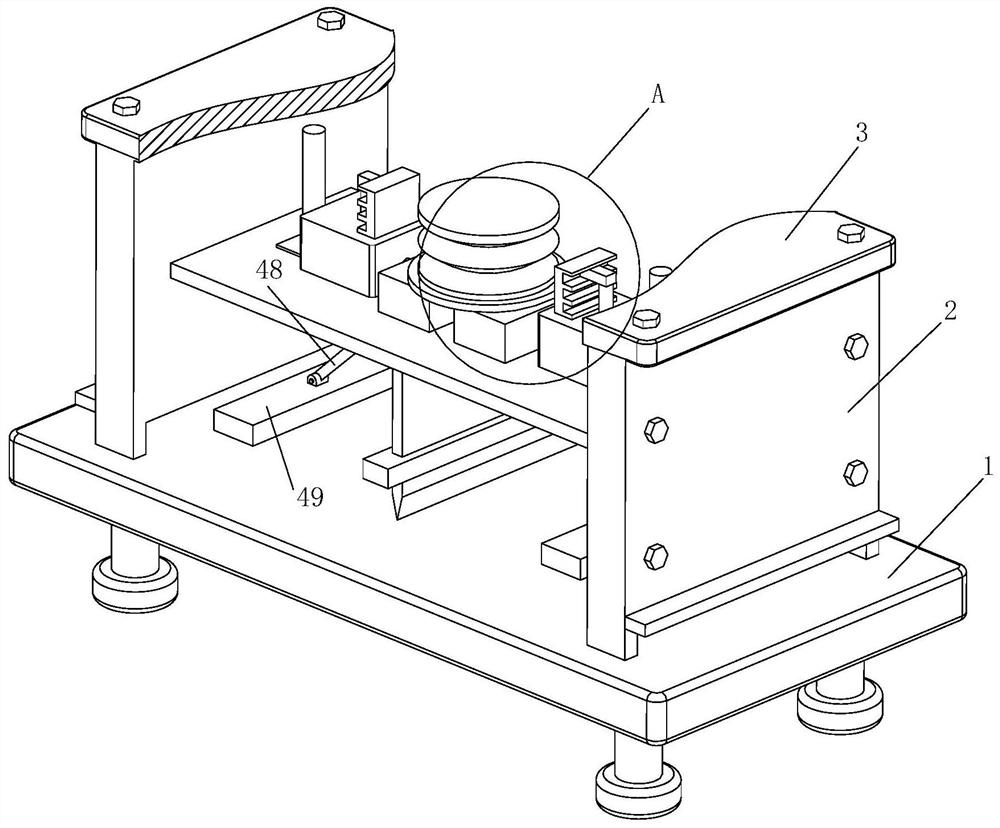

Adjustable clothing tailoring discharging tensioning structure

An adjustable and tensioning mechanism technology, applied in the field of clothing cutting, can solve the problems that the tension structure is difficult to adjust the tension force, fabric wrinkles, and affect the fabric cutting effect, so as to improve the overall use effect and avoid the reduction of tension force Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

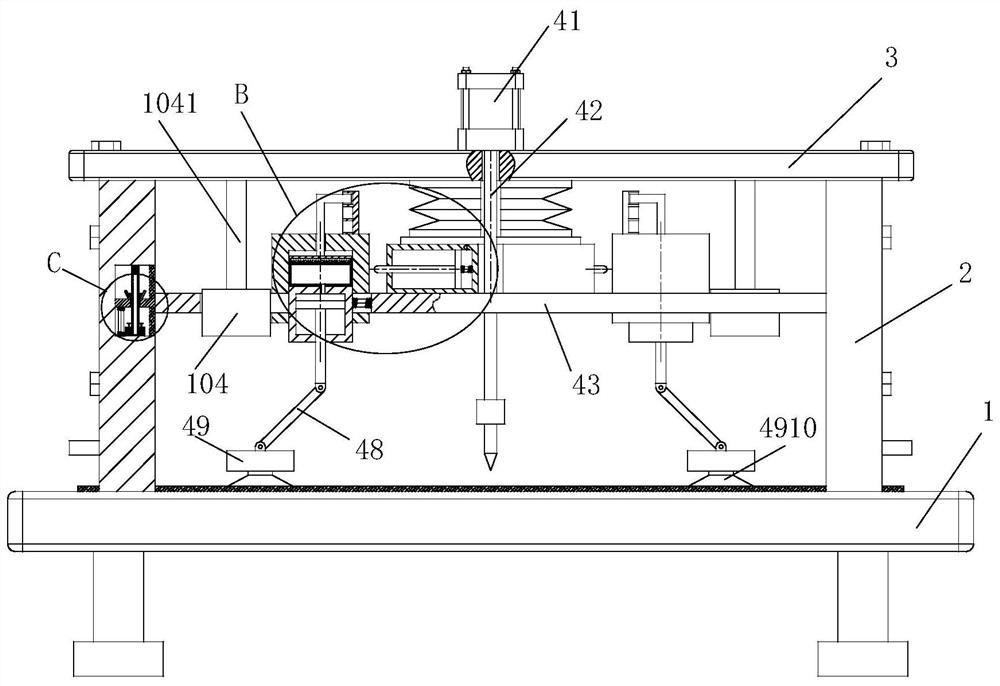

Method used

Image

Examples

Embodiment approach

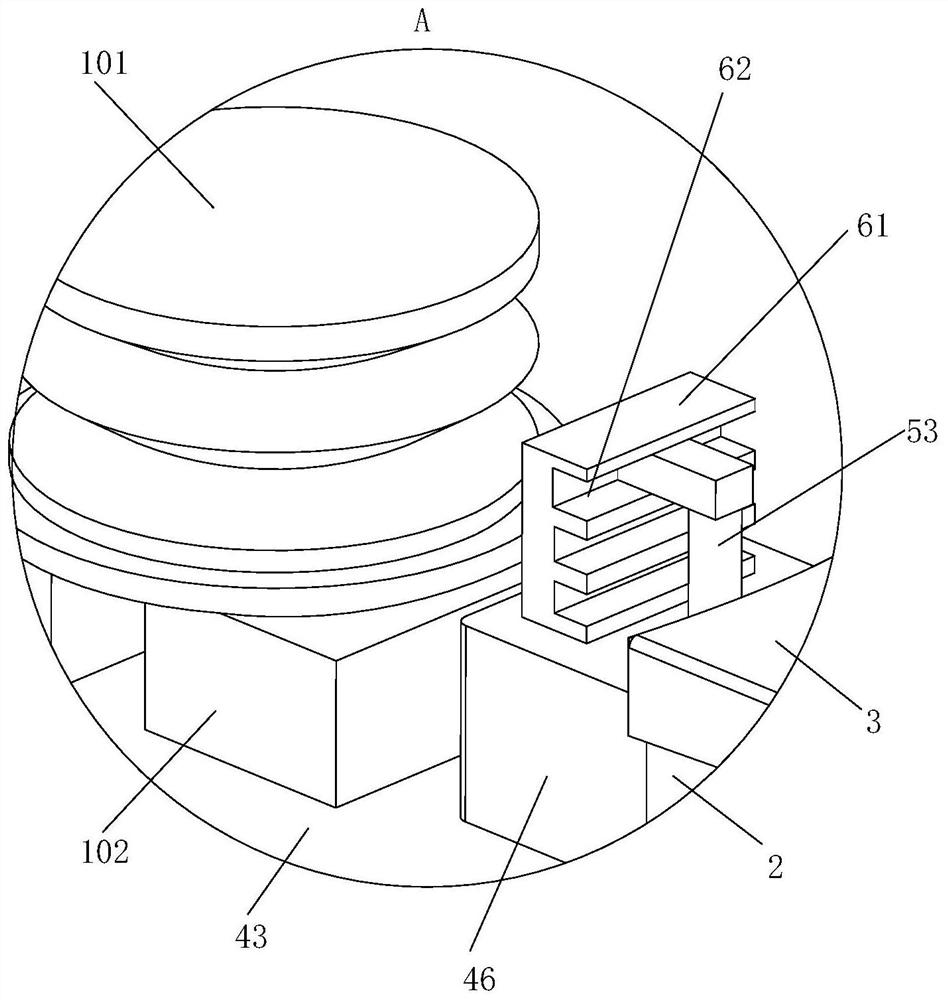

[0029] As an embodiment of the present invention, the bottom of the No. 2 push plate 52 is provided with an anti-friction assembly; the bottom of the No. 2 push plate 52 is provided with a No. 2 groove 71; the inner wall of the No. 2 groove 71 A slide plate 72 is slidably connected; an oil bag 73 is fixedly connected between the bottom of the second groove 71 and the slide plate 72; the slide plate 72 is uniformly provided with a through hole 74, and the oil bag 73 communicates with the through hole 74; During use, since the No. 2 push plate 52 constantly rubs against the upper surface of the circular airbag 51, the upper surface of the circular airbag 51 will be damaged, thereby reducing the service life of the circular airbag 51, so it can be reduced by the anti-friction assembly. The frictional force between the No. 2 push plate 52 and the circular airbag 51, at first when the No. 2 push plate 52 slides downward, when the circular airbag 51 is compressed and deformed, the sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com