A kind of hollow box-shaped reinforcement and preparation method thereof, and preparation method of hollow box

A reinforcement and hollow technology, applied in textiles, papermaking, textiles, fabrics, etc., can solve the problems of low rigidity of hollow box-shaped structural parts, scattered box top and box body, poor mechanical properties, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

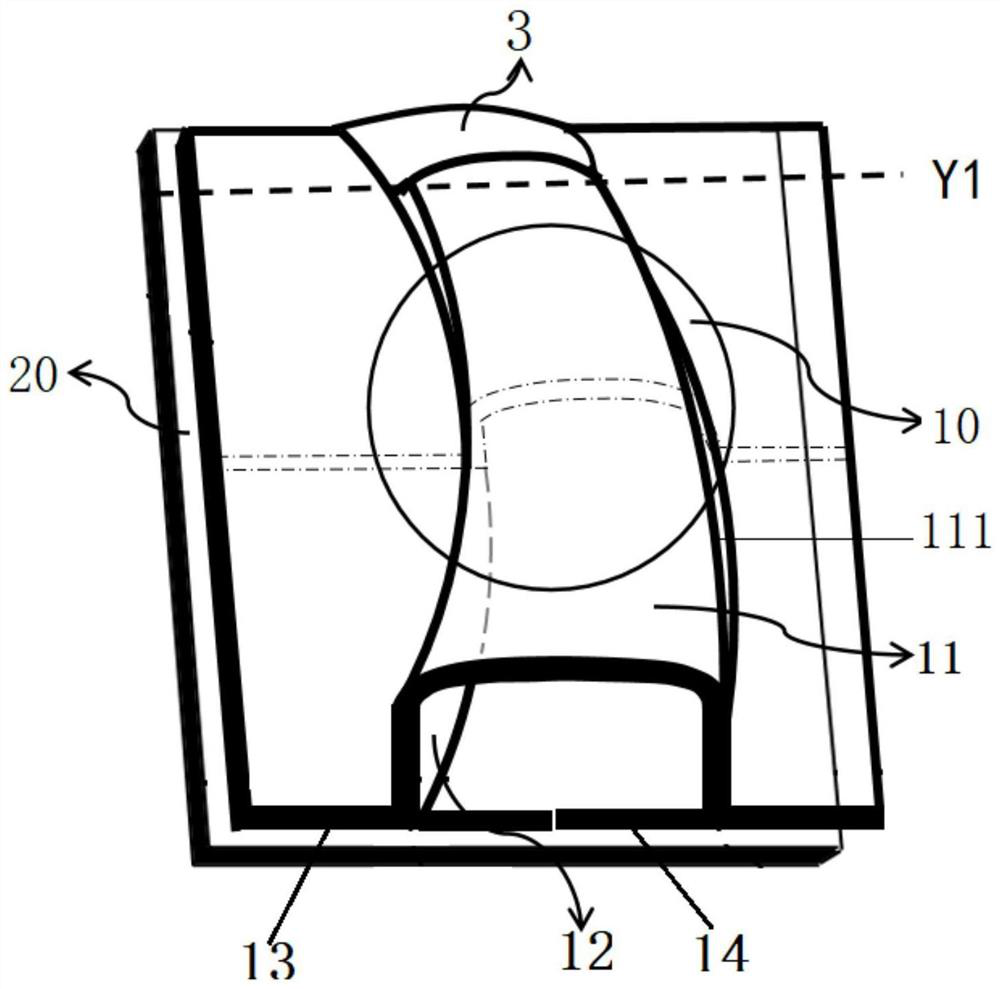

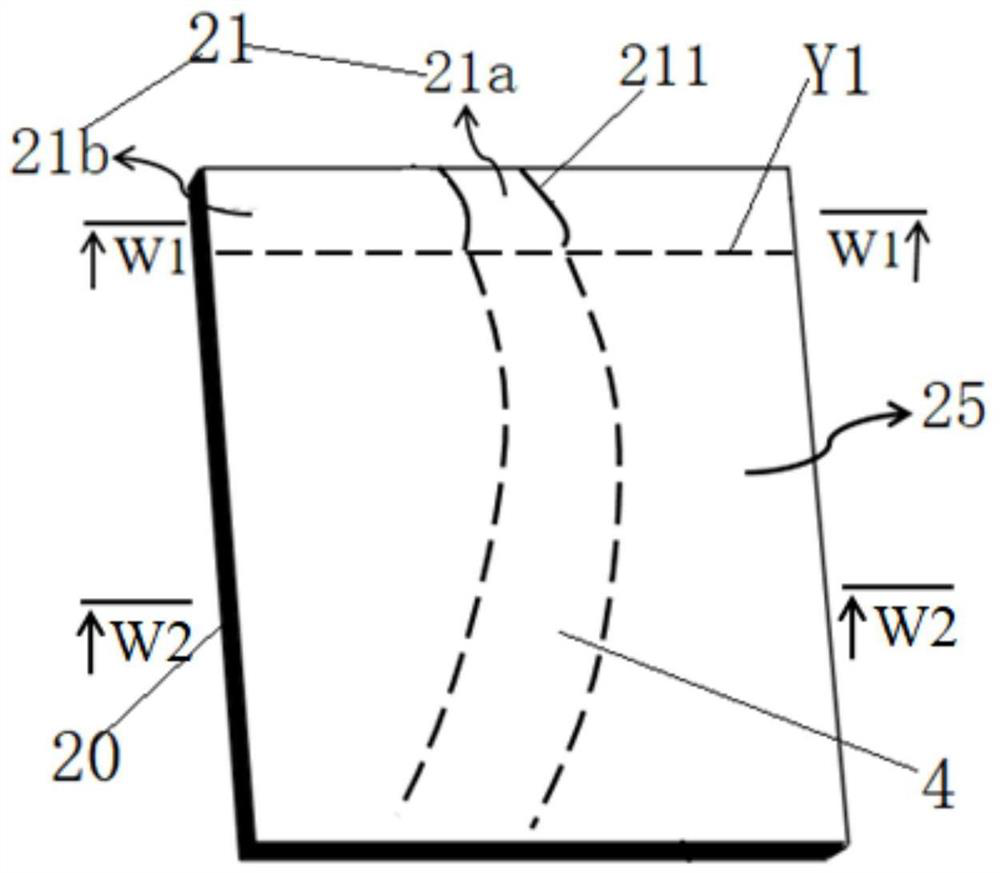

[0075] This embodiment provides a hollow box-shaped reinforcement, such as figure 1 As shown, it includes an integrally woven box bottom and an integrally woven box body; the box body includes a box top 11, two side walls 12 that are bent and extended downward from both sides of the box top 11, and the bottom of any side wall 12. The first connecting portion 13 bent outward from the top, the first connecting portion 13 is laminated and connected to the bottom of the box, and the second connecting portion woven with the first connecting portion 13 on the bottom of any side wall 12 in layers 14. The second connecting part 14 is bent inward, and the second connecting part 14 is in contact with the surface of the bottom of the box, with the side wall 12 of the box as the boundary, the first connecting part 13 and the second connecting part 14 are located at the bottom of the box. On both sides of the side wall 12, the end faces of the ends of the two second connecting parts 14 tha...

Embodiment 2

[0111] This embodiment provides a hollow box-shaped reinforcement, which is different from the hollow box-shaped reinforcement of Embodiment 1 in that:

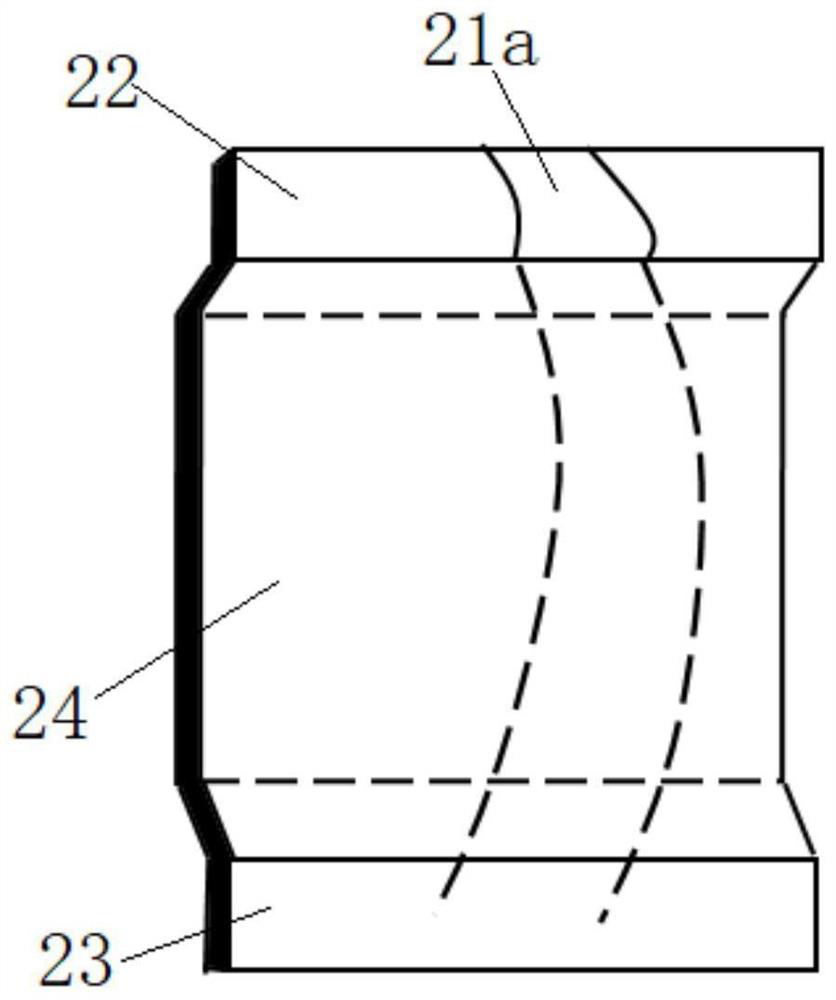

[0112] like figure 1 As shown, the bottom of the hollow channel in Embodiment 1 is a plane; while the bottom of the hollow channel in this embodiment is a groove 24, such as image 3 As shown, the shape of the hollow channel mainly depends on the shape of the middle mold, the bottom mold and the top mold.

[0113] Therefore, when the bottom of the hollow channel is the groove 24, the preparation method of the corresponding hollow box-shaped reinforcement is compared with the preparation method of the hollow box-shaped reinforcement in Example 1. The difference is:

[0114] S10 (opening the mold): the surface of the top mold of the prepared bottom mold is concave;

[0115] In the step S30 (stacking), when the box bottom preform is stacked on the top surface of the bottom mold, the bottom surface of the box bottom preform is ...

Embodiment 3

[0120] This embodiment provides a hollow box-shaped reinforcement, which is different from the hollow box-shaped reinforcement of Embodiment 1 in that:

[0121] The tail of the box bottom is not provided with a ladder, but the tail of the box top 11 is provided with a ladder, which can also make the middle of the tail of the box bottom and the middle of the tail of the top 11 abut through the ladder, so that the tail of the bottom of the box can be connected to the bottom of the box. When the tail of the box top 11 is attached and connected, the closed end 3 is formed.

[0122] Correspondingly, the difference between the preparation method of this hollow box-shaped reinforcement and the preparation method of Example 1 is:

[0123] In the weaving step of the box bottom preform 20, the multi-layer warp yarns and the multi-layer weft yarns are interwoven layer by layer to form a flat box bottom preform 20;

[0124] Before the weaving step of the box body preform 10, the preset h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com