Material taking and glue printing assembly, glue printing device and inner box manufacturing process of full-open type packaging box

A technology of glue printing and components, which is applied in box production, packaging, transportation and packaging, etc. It can solve the problems of deepening pollution of the glue head and the speed cannot meet the process requirements, so as to achieve high production efficiency and optimize station settings , the effect of liberating space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

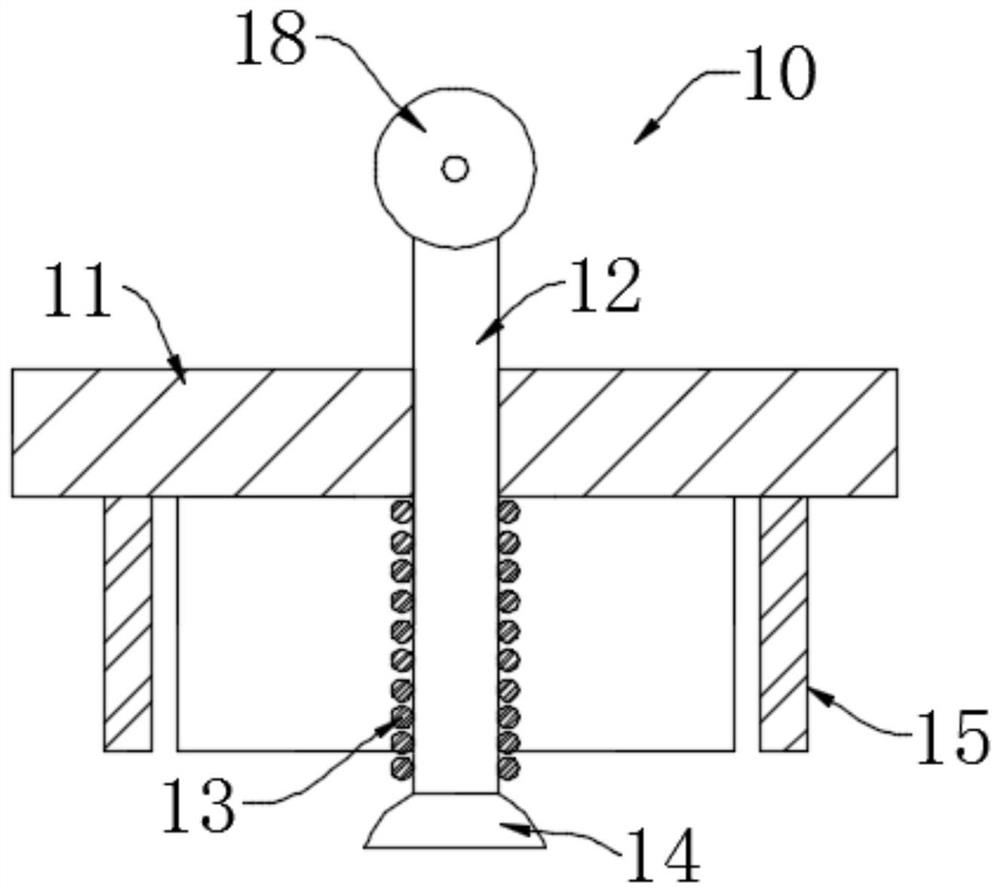

[0038] figure 2 A specific embodiment of a material-retrieving and printing glue assembly 10 provided by the present invention mainly includes a base 11, which is used to be connected to a power device so that it can move up and down automatically, and a through hole is opened in it, and a The connecting rod 12 penetrates through the hole, and the top of the rod (with reference to the paper) is indirectly connected to the upper bottom surface of the base 11 through a sliding module, so that the rod can slide relative to the base 11 under the action of an external force; The bottom end of the rod 12 is connected with a suction nozzle 14 , the gas path is opened inside the connecting rod 12 , and the spring 13 is sleeved on the rod between the bottom surface of the base 11 and the suction nozzle 14 .

[0039] The printing plate 15 is directly or indirectly installed under the base 11 , the four printing plates 15 are connected end to end to form a rectangle, and the suction noz...

Embodiment 2

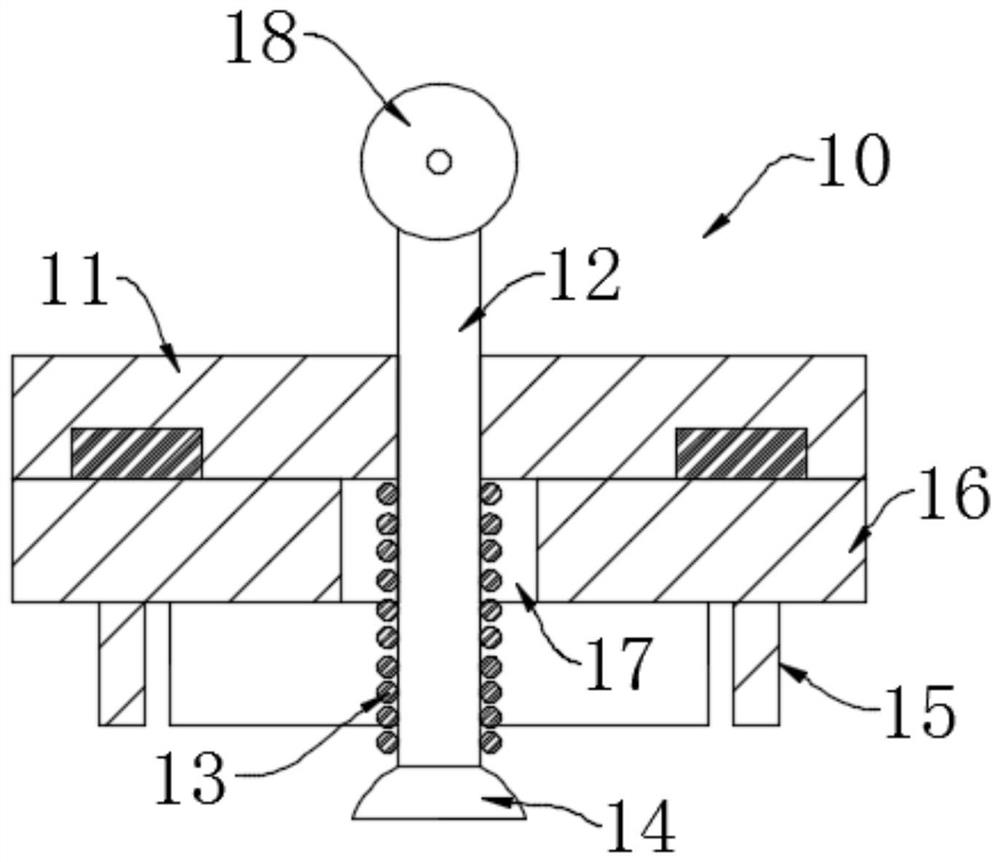

[0041] like image 3 , in order to facilitate fine-tuning and removal of the connecting rod 12, the connecting plate 16 is used to realize the indirect installation of the rubber plate 15, and the upper bottom surface of the connecting plate 16 and the lower bottom surface of the base 11 realize sliding assembly through the chute slider structure. The top of the spring 13 is still limited by the limit plate 11. It is convenient that the connecting rod 12 can be adjusted in the hole 17 to adapt to substrates of different specifications.

[0042] The above two embodiments can not only realize the two functions of taking material and printing rubber, but also the connecting rod 12 and spring 13 can also play the role of demoulding after the rubber printing plate is printed. Because of the effect of glue, the printing rubber plate 15 and the rubber printing plate There is still stickiness between the substrates, and external force is required to demould when demolding, while the c...

Embodiment 3

[0044] Figure 4 For the above-mentioned embodiment, in the automatic gluing device 50, the material-taking and printing-gluing assembly 10 is connected with a rotating main shaft 52, and the main shaft 52 is rotated, and the main shaft 52 can move up and down at the same time. A turntable 51 is arranged at the bottom of the main shaft 52 , and four extensions are arranged on the rotation shaft 51 , and the extensions are fixedly connected with the base 11 . Below the extension part, a glue dipping station 511, a suction station 512, a glue printing station 513, and a glue washing station 514 are sequentially arranged. Wherein, a printing rubber pool is set at the glue dipping station 511, and a stopper 9 is also set above the printing rubber pool, and a roller 18 is installed on the top of each corresponding connecting rod 12. When the main shaft 52 drives the turntable 51 to rotate , at the glue dipping station 511, move downwards, take out the glue printing assembly 10 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com