Post-welding surface treatment device

A surface treatment device and post-welding technology, which is applied in the direction of lighting devices, lighting devices, grinding drive devices, etc., can solve the problems of splashing metal debris, increasing the labor intensity of workers, and inconvenient rapid switching of the position of grinding devices. Achieve the effect of increasing the scope of application and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

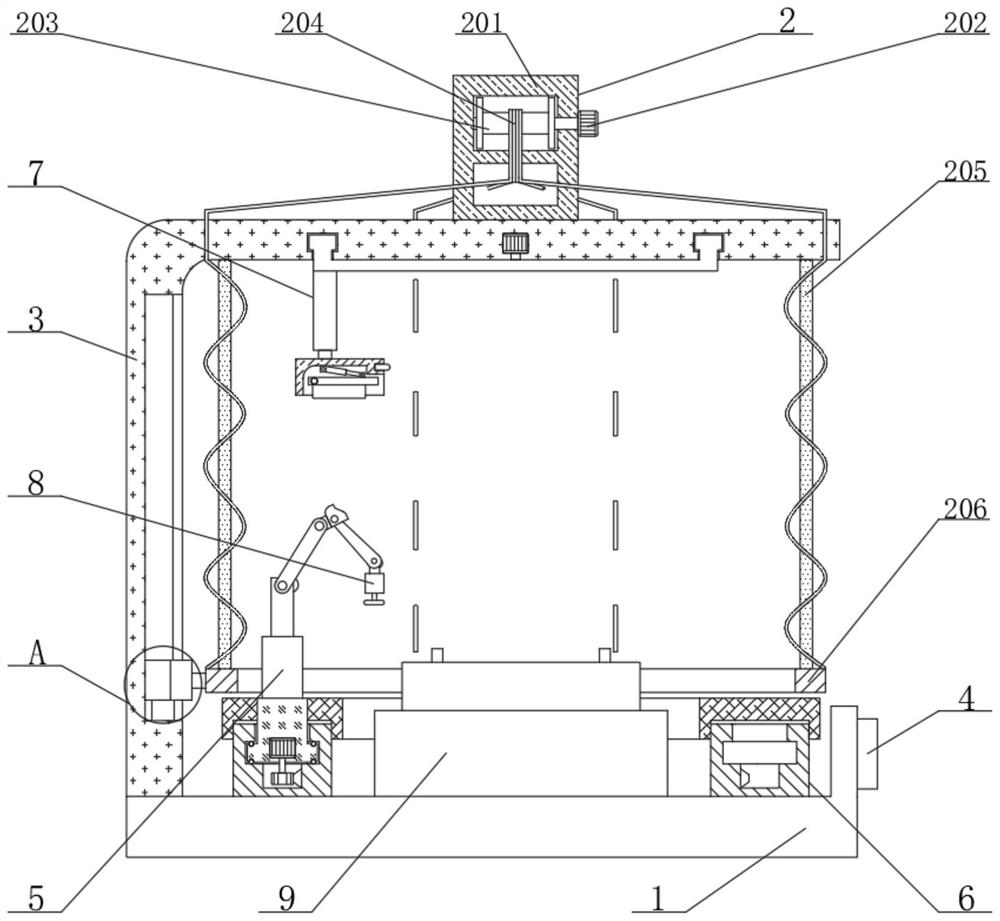

[0025] see figure 1 , figure 2 , image 3 , Figure 4 with Figure 5 , the present invention provides a technical solution:

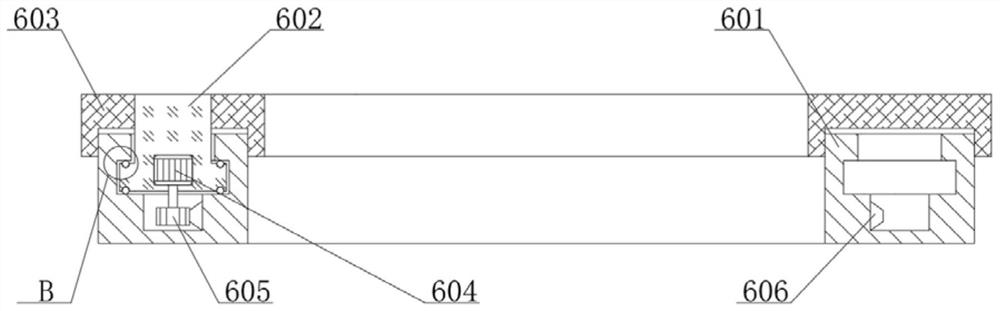

[0026]A surface treatment device after welding, comprising a base 1, a shielding device 2, a switching device 6, and a monitoring and viewing device 7, a clamp 9 is fixedly connected to the center of the top of the base 1, and a switching device 6 is provided on the outside of the clamp 9, and the switching device 6 It is fixedly connected with the base 1, the switching device 6 includes a slide rail 601, and the outside of the clamp 9 is provided with a slide rail 601, and the slide rail 601 is fixedly connected with the base 1, and the inner left end of the slide rail 601 is slidably connected with a slider 602, and the outside of the slider 602 is up and down. Ball blocks 607 are provided at both ends, and the ball blocks 607 are rotatably connected to the slider 602, and the ball blocks 607 are rotatably connected to the slide rail 601. This se...

Embodiment 2

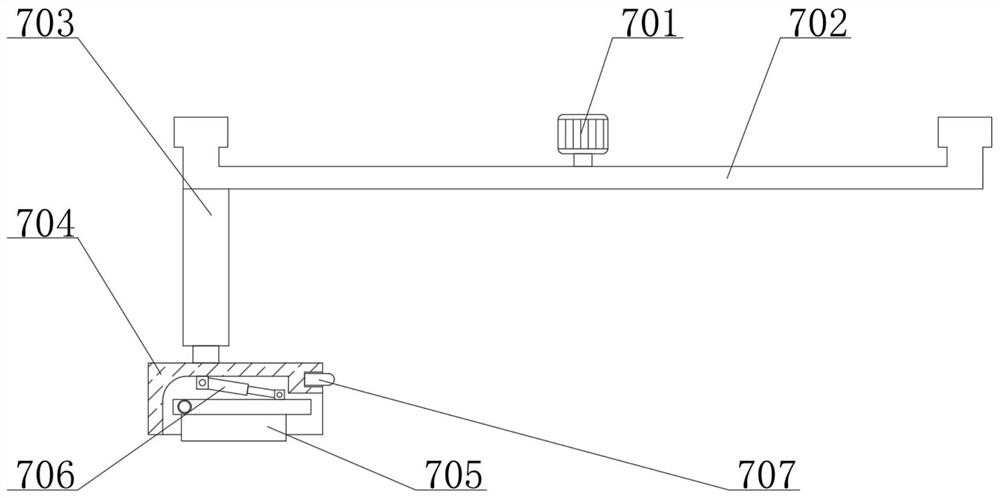

[0029] The same parts as those in Embodiment 1 will not be repeated in Embodiment 2. The difference is that the present invention provides a technical solution: a lighting lamp 707 is provided on the top right side of the fixing frame 704, and the lighting lamp 707 is fixed to the fixing frame 704. Connection, when using the device in poor light conditions, the device can be controlled by the remote control mechanism, and the grinding status of the metal can be clearly checked in real time, without going to the grinding site to check, which not only reduces the labor of the staff strength, and also increases the range of application of the device.

[0030] Workflow: When checking the grinding status, when the light is poor and the monitoring picture is not clear, the lighting lamp 707 can be activated through the controller 4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com