Customized assembly type decoration material sorting mechanism and using method

A prefabricated and material machine technology, applied in the field of material processing, can solve the problems affecting the overall flow efficiency of materials, inability to classify various types of plates, and low utilization rate of classification equipment, achieving high utilization rate, low error rate, and high intelligence. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

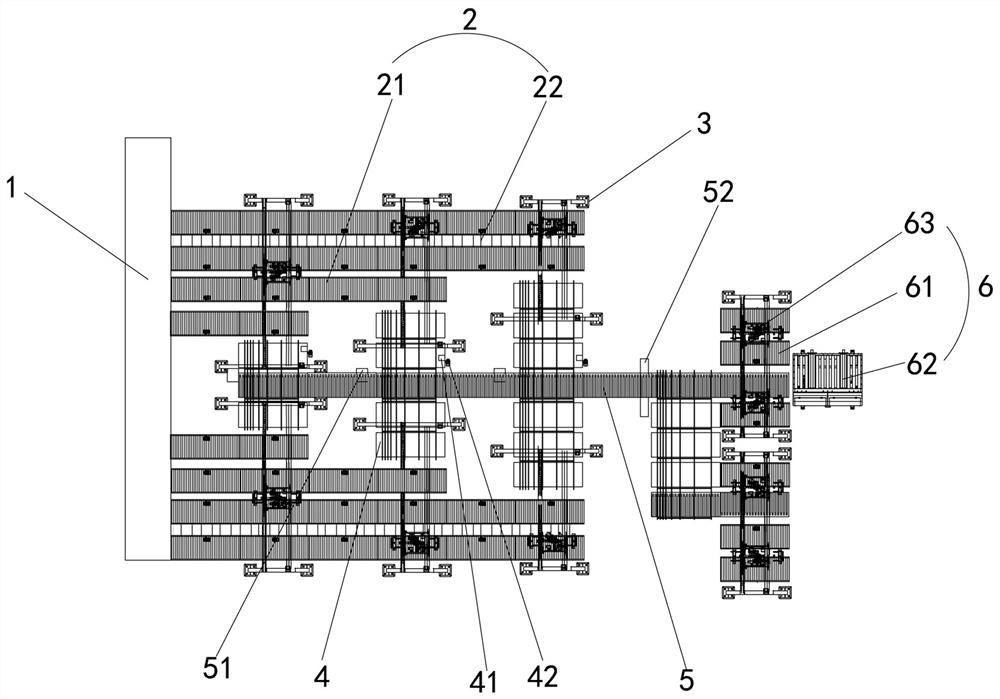

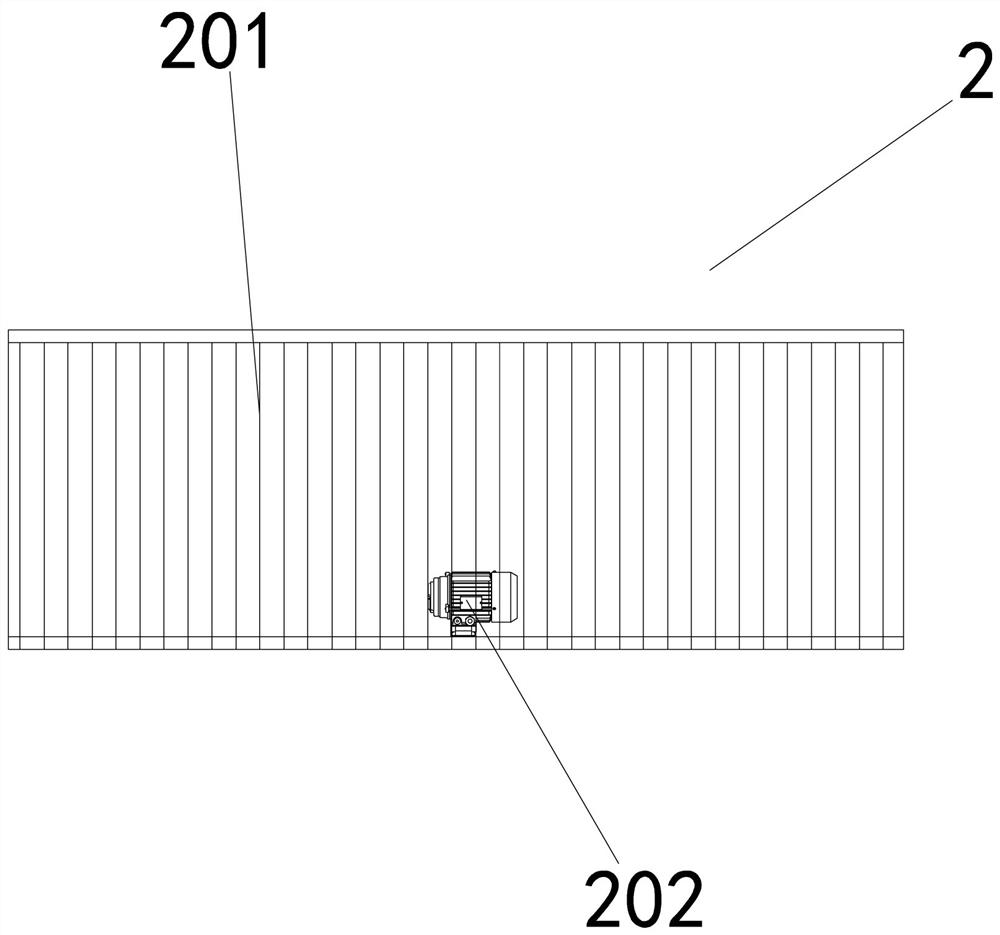

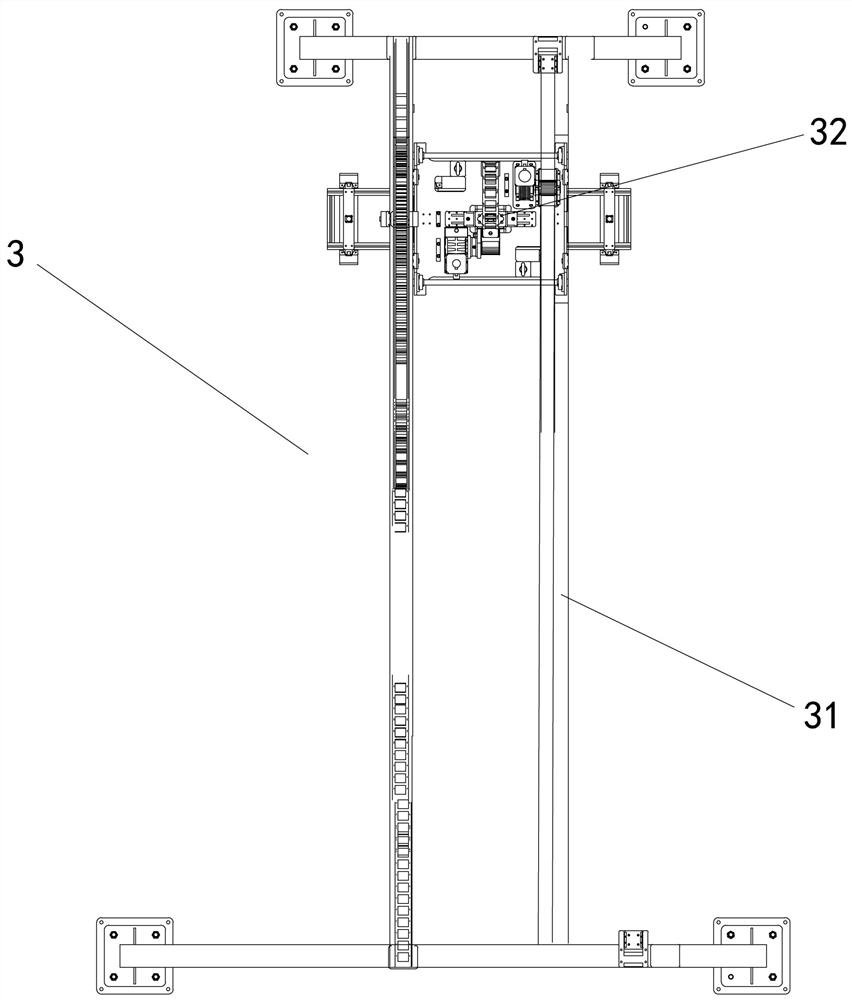

[0038] Embodiment one: if Figures 1 to 3As shown, it is only one of the embodiments of the present invention, a custom-made assembled decoration material sorting mechanism, including a main transmission line 1, a transmission line 2 connected to the main transmission line 1, and a transmission line 2 arranged at the end of the transmission line 2 The feeding machine 3 of the part, the pre-conveyor belt 4 arranged at the end of the feeding machine 3, the main conveyor belt 5 connected with the said pre-conveyor belt 4, and the sorting part 6 arranged at the end of the main conveyor belt 5, the conveying The line 2 includes a single conveying line 21 connected by at least one power roller 201 and a multiple conveying line 22 connected by at least two rows of the same number of power rollers 201, a power motor 202 is arranged below the power roller 201, and the feeder 3 includes a slide rail 31 arranged vertically to the conveying line 2 and a loading handle 32 arranged on the s...

Embodiment 2

[0049] Embodiment two, still as Figures 1 to 3 As shown, it is only one of the embodiments of the present invention. On the basis of Embodiment 1, in a custom-made assembled decoration material sorting mechanism of the present invention, the conveying line 2 is arranged in parallel with the main conveying belt 5, close to The number of power rollers 201 of the conveying line 2 of the main conveyor belt 5 is smaller than the number of power rollers 201 of the conveying line 2 far away from the main conveyor belt 5, and the transmission speed of the power rollers 201 is not greater than that of the main conveyor belt 5. The transmission speed of the conveyor belt 5. Generally speaking, when the main conveyor belt 1 is on the conveyor line 2, the larger the transported piece is placed on the conveyor line 2 farther away from the main conveyor belt 5, and the longer the conveyor line 2 is, the farther it is from the main conveyor belt 5. The time to reach the main conveyor belt ...

Embodiment 3

[0051] Embodiment three, still as Figures 1 to 3 As shown, it is only one of the embodiments of the present invention. On the basis of Embodiments 1 and 2, in a custom-made assembled decoration material sorting mechanism of the present invention, the length of the feeder 3 and the pre-conveyor belt 4 can be It is known that the sum of the length of the feeder 3 and the length of the pre-conveyor belt 4 is not less than the distance between the conveyor line 2 and the main conveyor belt 5. In fact, each conveyor line 2 tail end is provided with a bridge spanning the farthest The conveyor line 2 at the end (the multi-conveyor line 22 at the farthest end) to the feeder 3 of the pre-conveyor belt 4, that is to say, the longer the conveyor line 2 is, the more the number of feeders 3 across is, and further Yes, a fourth camera is provided on the feeding gripper 32, so the longer the conveying line 2 is during the transportation of the conveying piece, the size of the conveying piec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com