Quick installation type ice-melting short-circuit wire clamp

A short-circuit and ice-melting technology, used in the power grid field, can solve the problems of weak connection, poor electrical conductivity, low work efficiency, etc., and achieve the effect of avoiding self-relaxation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

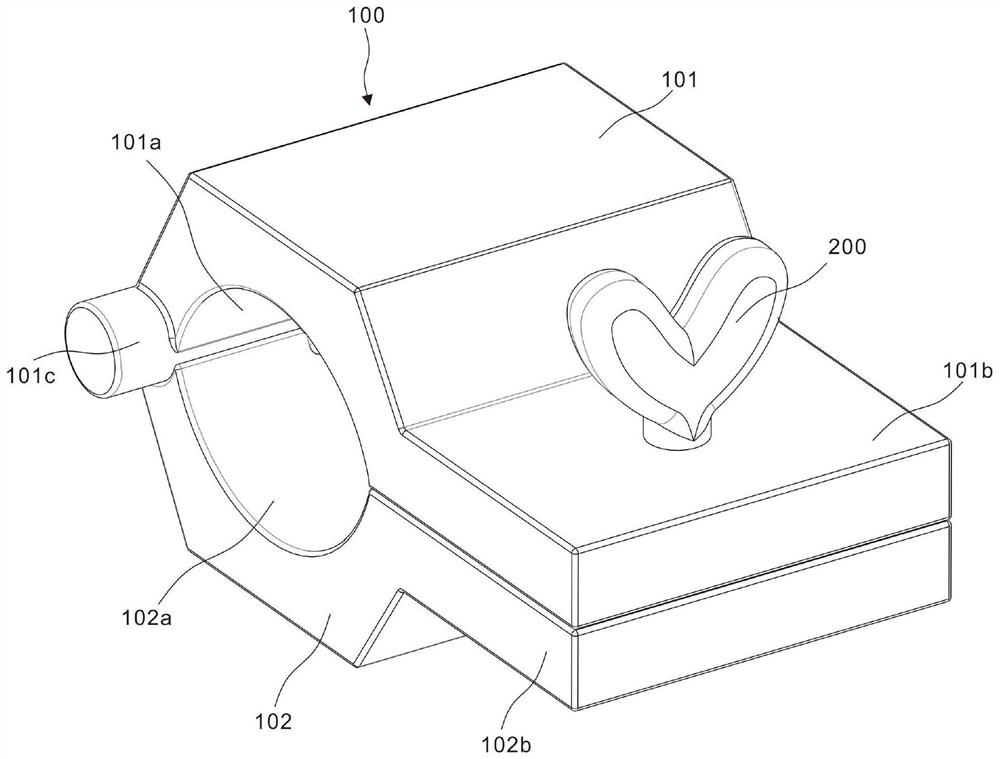

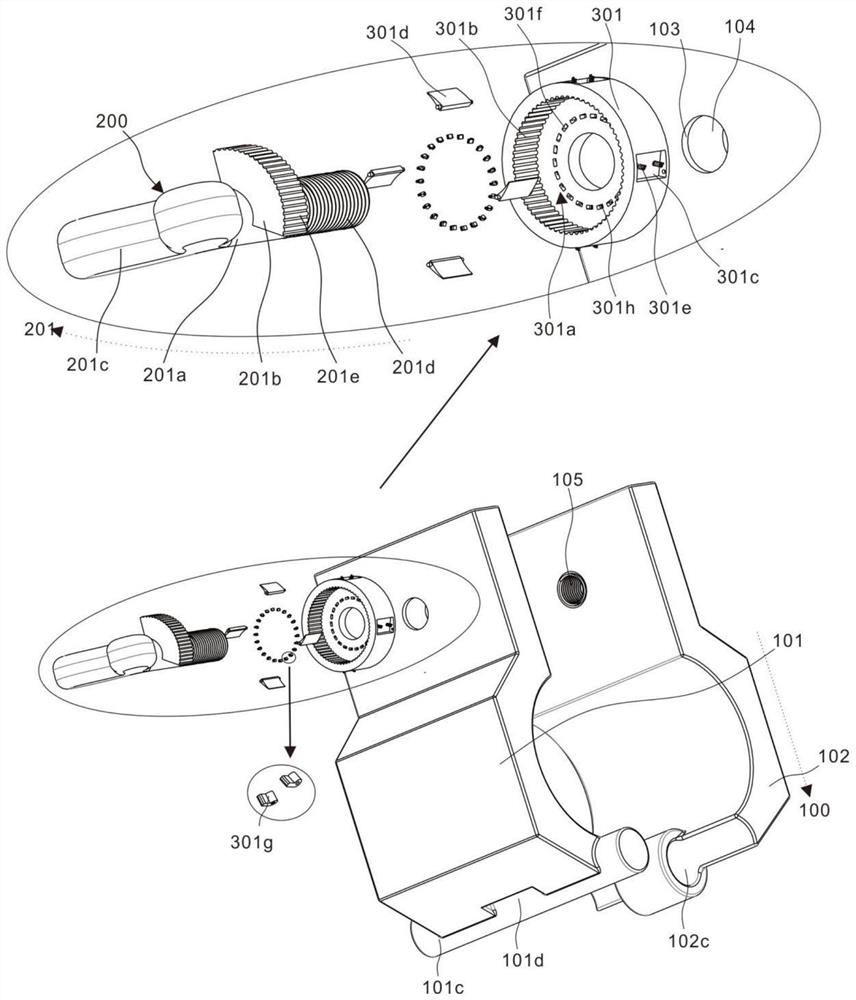

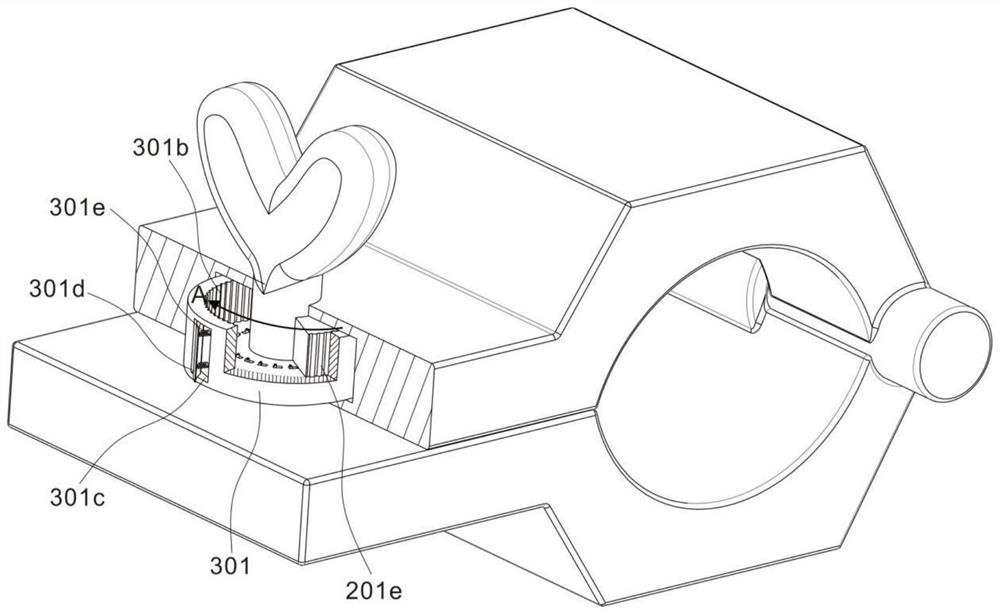

[0034] refer to Figure 1~5 , this embodiment provides a quick-installation type ice-melting short-circuit clip, including,

[0035] The clamping assembly 100 includes a first clamping plate 101 and a second clamping plate 102, one end of the first clamping plate 101 and the second clamping plate 102 are axially connected, the first clamping plate 101 is provided with a first cavity 101a, and the second clamping plate 102 is provided with a second Two concave cavities 102a, the positions of the first concave cavity 101a and the second concave cavity 102a are corresponding;

[0036] The first splint 101 is provided with a first platform 101b, and the second splint 102 is provided with a second platform 102b;

[0037] The fastening assembly 200 includes a screw joint 201, and the screw joint 201 connects the first platform 101b and the second platform 102b;

[0038] The anti-loosening component 300 and the anti-loosening component 301 are arranged at the joint between the scre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com