Large-aperture telescope supporting assembly

A technology for supporting components and telescopes, applied in the field of space remote sensing, can solve the problems of low precision, damage to the mirror body, and long time consumption, and achieve the effects of ensuring accuracy, avoiding crushing, and convenient positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

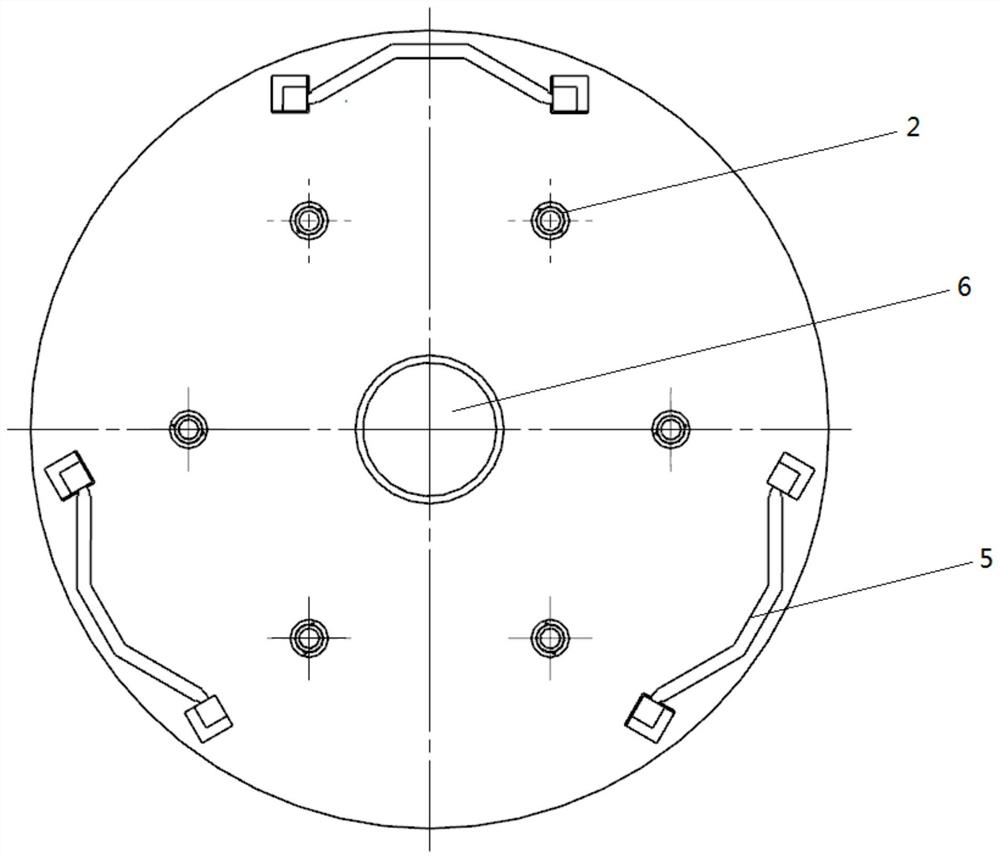

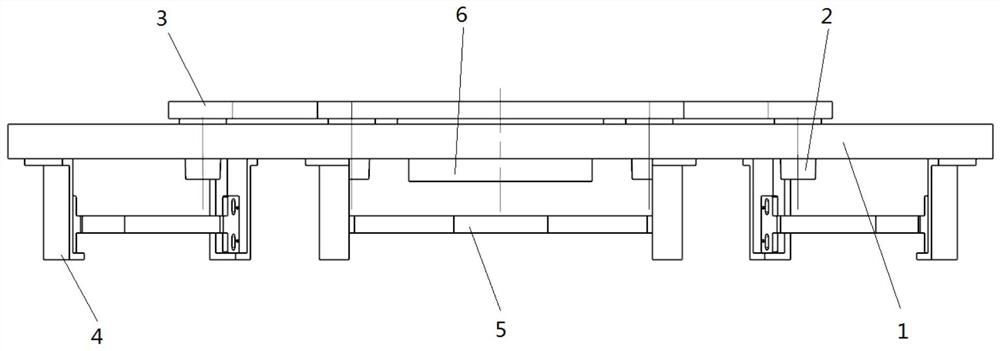

[0038] An embodiment of the present application provides a support assembly for a primary mirror of a large-aperture telescope, including a back support assembly and a peripheral support assembly. The primary mirror is arranged on the top of the back support assembly, and the peripheral support assembly is arranged on the back support assembly. At the bottom, the main mirror central positioning sleeve (6) is arranged on the back support assembly, and the main mirror central positioning sleeve (6) is coaxial with the central axis of the back support assembly.

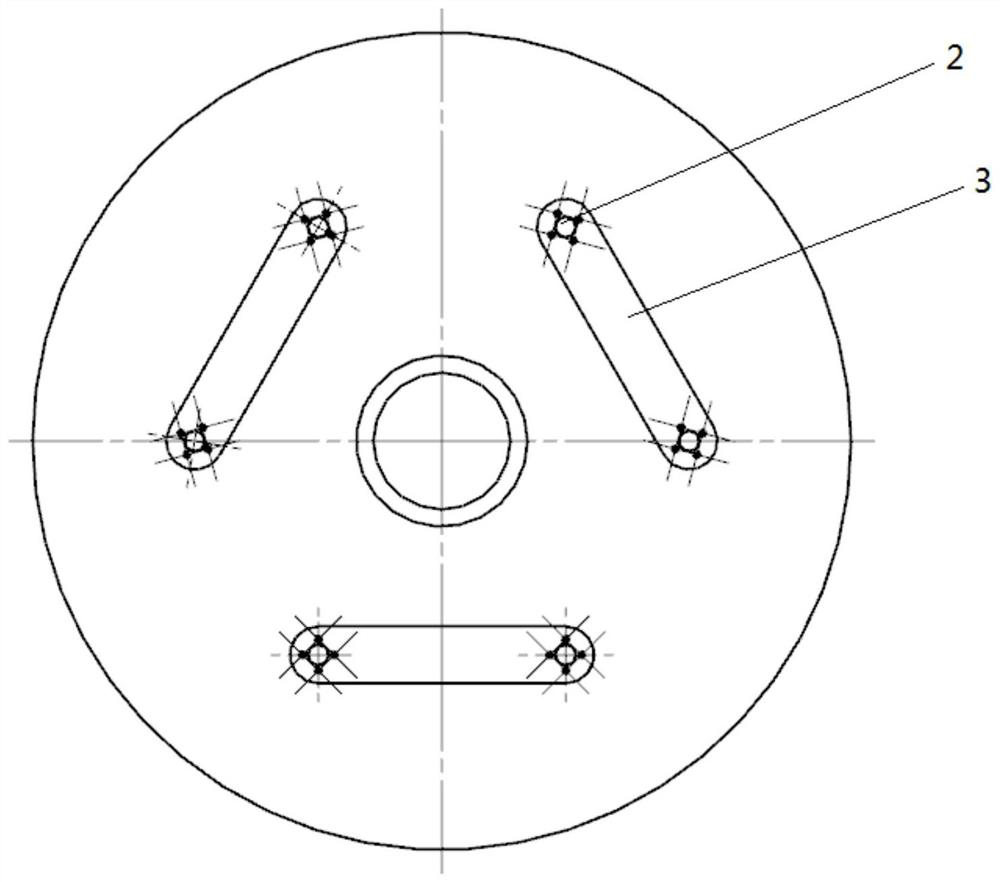

[0039] The back support assembly comprises a back cover plate (1), a back positioning bushing (2), and a back positioning bushing connecting a cross bar (3). 6 holes are evenly arranged on the back cover plate (1), and the back positioning bushings (2) matched therewith are respectively arranged in the 6 holes; the back positioning bushings (2) can avoid the main mirror The mirror body is crushed by the circular back cov...

Embodiment 2

[0045] The embodiment of the present application provides a method for positioning the main mirror support assembly of a large-aperture telescope, including the following specific steps:

[0046] 1. The positioning of the back support assembly, so that the back cover (1) and the main mirror are installed together:

[0047] 1) Place the primary mirror of the support assembly to be installed facing downward;

[0048] 2), place the back positioning bushing (2) in the positioning hole of the back cover plate (1) through the screw hole on the back positioning bushing (2);

[0049] 3) Place the back cover (1) on the back of the main mirror through the back positioning bushing (2), and then determine the relative position of the main mirror and the back cover (1) through the center positioning bushing (6) of the main mirror;

[0050] 4), connect the back positioning bushing (2) by connecting the cross bar (3) with the back positioning bushing provided with threaded holes, so as to r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com