Measuring controllable differential drilling-reaming two-purpose drill rig

A differential type, drilling rig technology, used in construction, sheet pile wall, infrastructure engineering and other directions, can solve the problems of inability to monitor and control the reaming process, the efficiency is too high, the drill bit mechanism is too large, etc., to achieve detection and procedures. Simple and easy control, simple structure, light and efficient, simple and reasonable force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

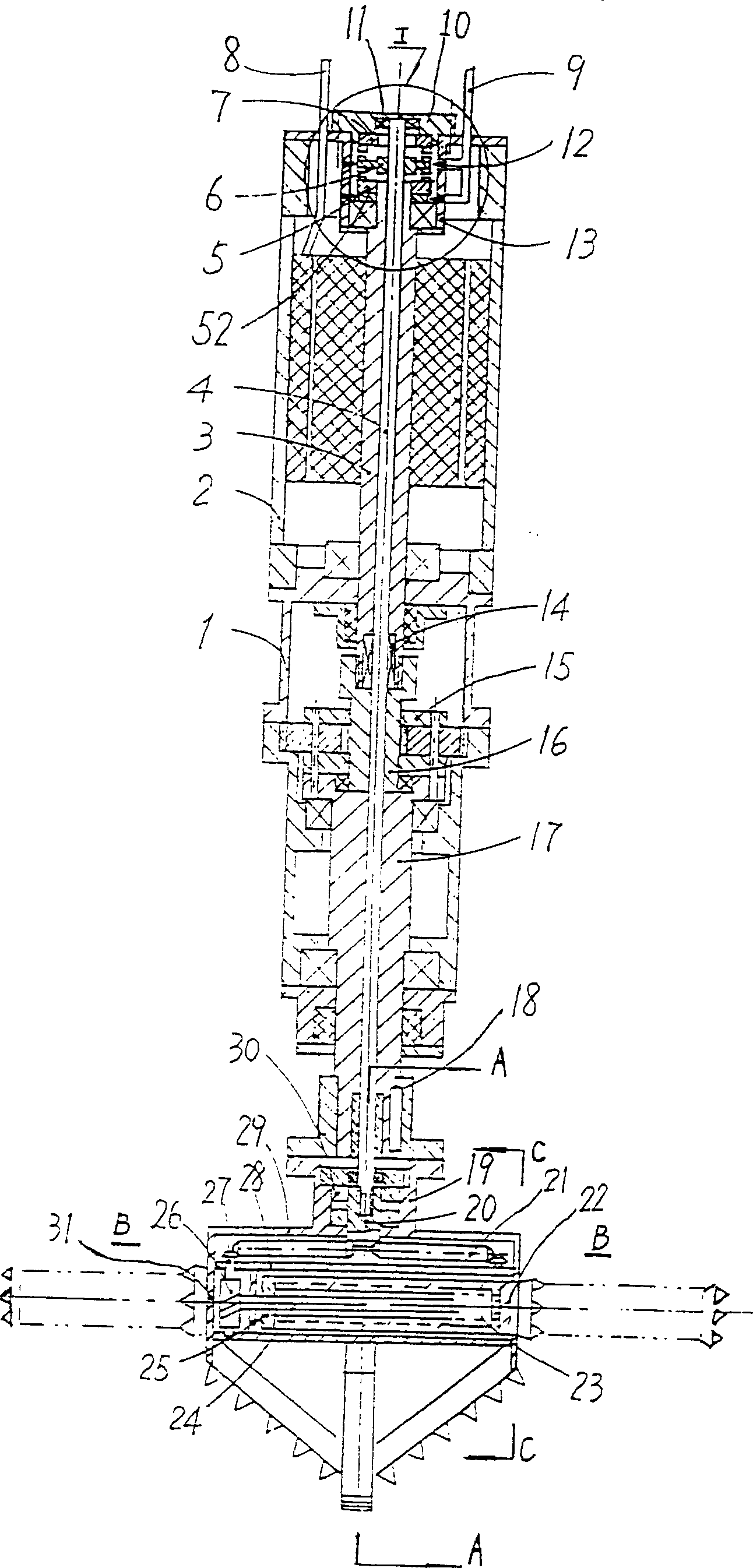

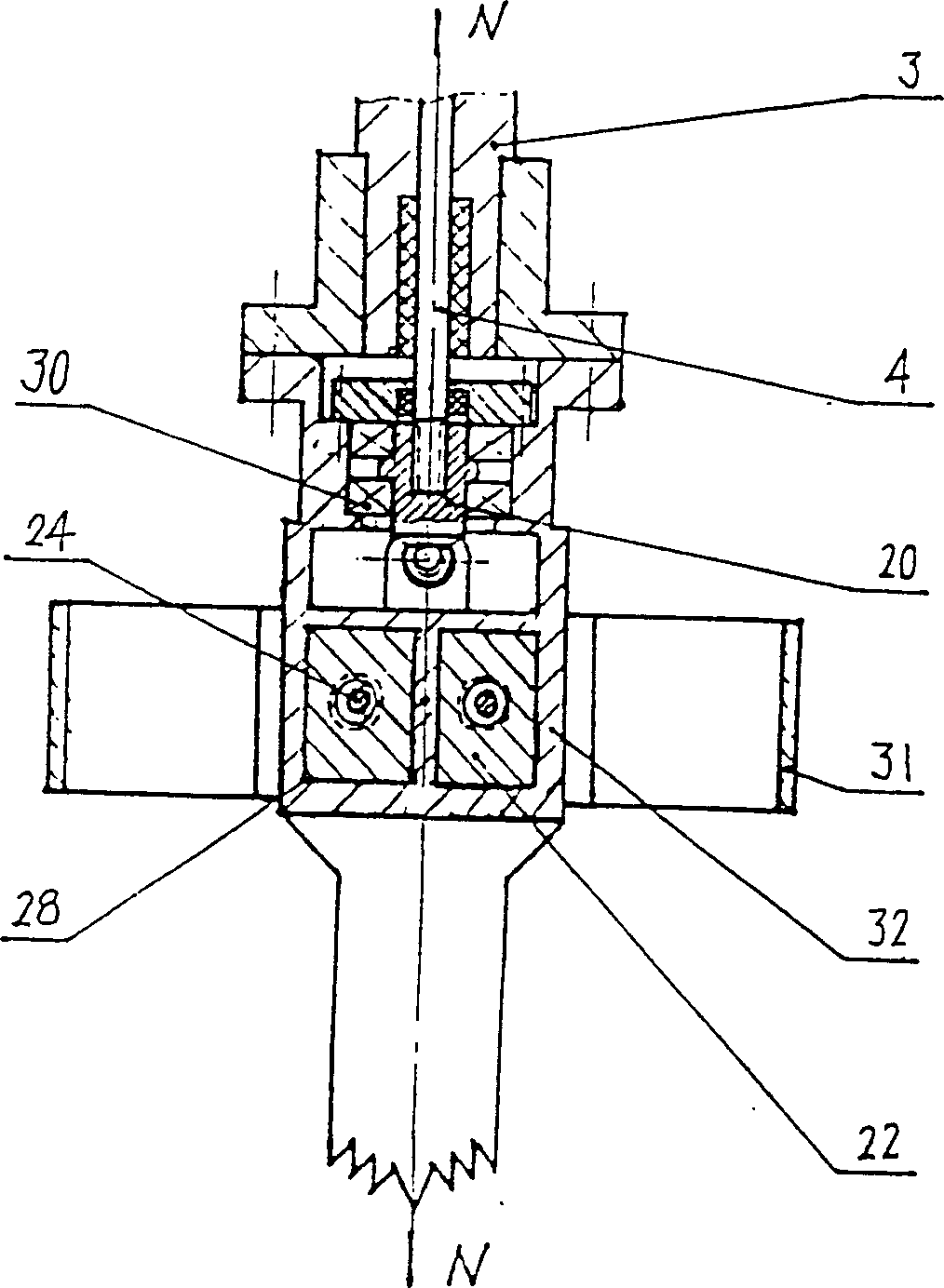

[0036] The measurable and controllable differential drilling and reaming dual-purpose drilling rig 1 shown in Fig. 1 is composed of a submersible motor 2, a planetary reducer 15, a drilling machine shaft 17 and a flange 18 on the shaft to form the power transmission route of the drilling machine 1 drilling. At this moment, the power cable 8 feeds the current into the stator coil of the submersible motor 2, and the motor rotor and the motor shaft 3 are rotated under the action of its magnetic field force, and the shaft 3 is connected to the sun gear shaft 16 and the Its star wheel and planetary gear frame rotate, and drive the drilling machine shaft 17 that is fixedly connected with the planetary wheel frame to rotate, connect the flange 18 on the drilling machine 17 with the flange of the drill bit 19, transmit power to the drill bit 19 and drive the drill bit 19 to rotate drilling.

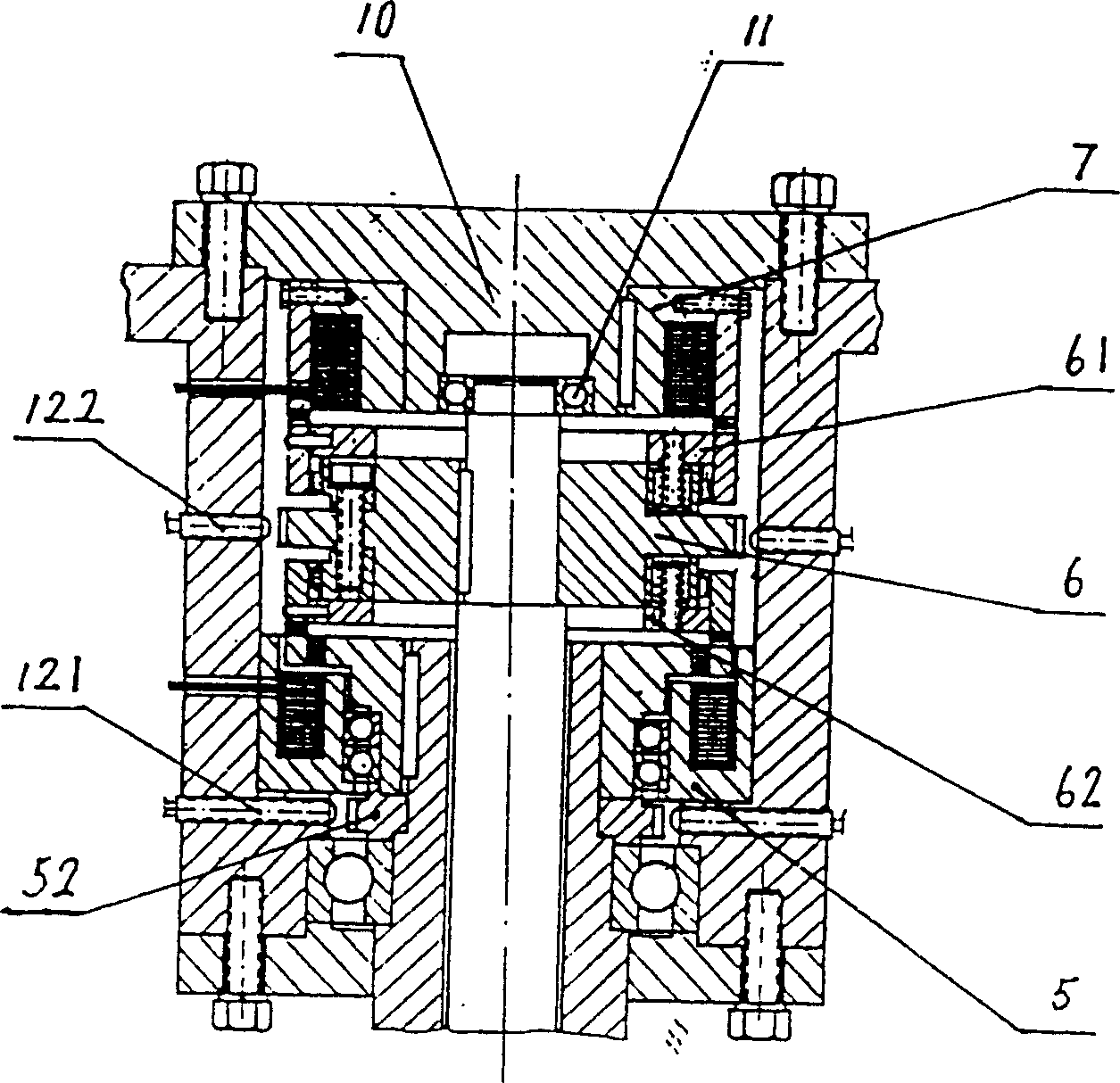

[0037]In order to make the drilling machine 1 form a differential output, the magnetic yoke 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com